Building glass thermal-insulation antifouling paint and preparation method thereof

An anti-fouling paint, architectural glass technology, applied in the direction of coating, can solve problems such as harmful substances, and achieve the effect of reducing solar radiation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

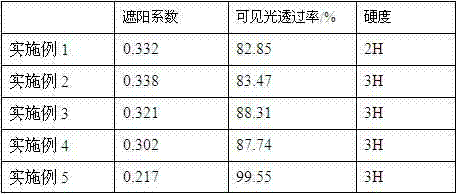

Examples

Embodiment 1

[0022] A thermal insulation and antifouling coating for architectural glass, the components and the parts by mass of each component are as follows: 15 parts of methyl methacrylate, 5 parts of styrene, 10 parts of tricresyl phosphate, 5 parts of cellulose acetate butyrate, acetic acid 20 parts of butyl ester, 8 parts of xylene, 6 parts of dipentene, 4 parts of linolenic acid, 4 parts of corn starch sulfosuccinate, 6 parts of phthalic anhydride, 0.46 parts of methyl hydroxypropyl cellulose , 10 parts of chlorinated paraffin, 5 parts of benzoyl peroxide, 7 parts of propylene glycol methyl ether, 1 part of antioxidant dibutyl hydroxytoluene, 6 parts of light stabilizer phenyl hydroxybenzoate, surfactant dodecane 8 parts of sodium base benzene sulfonate, 5 parts of dispersant triethylhexyl phosphoric acid.

[0023] The preparation method comprises the following steps:

[0024] 1) Add methyl methacrylate, styrene and tricresyl phosphate into the reactor, stir and heat up to 40°C; ...

Embodiment 2

[0028] A thermal insulation and antifouling coating for architectural glass, the components and the parts by mass of each component are as follows: 7 parts of methyl methacrylate, 3 parts of styrene, 6 parts of tricresyl phosphate, 1 part of cellulose acetate butyrate, acetic acid 10 parts of butyl ester, 3 parts of xylene, 1 part of dipentene, 1 part of linolenic acid, 1 part of corn starch sulfosuccinate, 2 parts of phthalic anhydride, 0.08 part of methyl hydroxypropyl cellulose , 4 parts of chlorinated paraffin, 2 parts of benzoyl peroxide, 1 part of propylene glycol methyl ether, 0.1 part of antioxidant dibutyl hydroxytoluene, 3 parts of light stabilizer phenyl hydroxybenzoate, surfactant dodecane 4 parts of sodium base benzene sulfonate, 1 part of dispersant triethylhexyl phosphoric acid.

[0029] The preparation method comprises the following steps:

[0030] 1) Add methyl methacrylate, styrene and tricresyl phosphate into the reactor, stir and heat up to 40°C;

[0031]...

Embodiment 3

[0034] A thermal insulation and antifouling coating for architectural glass, the components and the parts by mass of each component are as follows: 10 parts of methyl methacrylate, 4 parts of styrene, 7 parts of tricresyl phosphate, 2 parts of cellulose acetate butyrate, acetic acid 13 parts of butyl ester, 5 parts of xylene, 3 parts of dipentene, 2 parts of linolenic acid, 2 parts of corn starch sulfosuccinate, 3 parts of phthalic anhydride, 0.18 parts of methyl hydroxypropyl cellulose , 5 parts of chlorinated paraffin, 3 parts of benzoyl peroxide, 3 parts of propylene glycol methyl ether, 0.1 part of antioxidant dibutyl hydroxytoluene, 4 parts of light stabilizer 2,4-dihydroxybenzophenone, surface active Agent sodium dodecylbenzene sulfonate 5 parts, dispersant 2 parts methyl pentanol.

[0035] The preparation method comprises the following steps:

[0036] 1) Add methyl methacrylate, styrene and tricresyl phosphate into the reactor, stir and heat up to 40°C;

[0037] 2) Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com