Glass reinforced UV adhesive and preparation method thereof

A technology of glass reinforcement and oligomers, applied in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve performance stability and operability to be improved, glass strength improvement does not help, colloidal bonding Insufficient strength and other problems, to achieve the effect of beautiful appearance, good colloidal strength and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

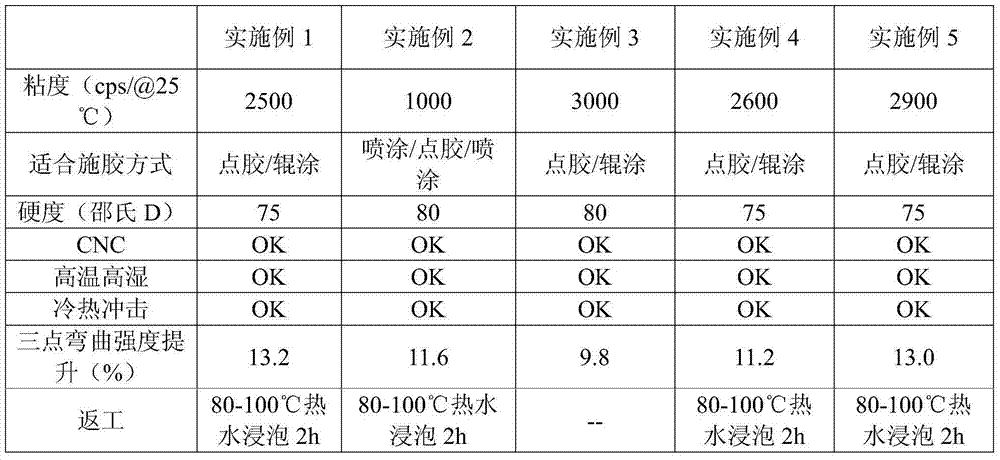

Examples

Embodiment 1

[0037] This example is a control example of colorless and transparent UV light curing. This embodiment provides a glass reinforced UV adhesive.

[0038] A glass-reinforced UV adhesive consisting of the following raw materials:

[0039] Oligomer: polybutadiene acrylate 32g;

[0040] Active monomer: 28g of monofunctional acrylate active monomer isobornyl methacrylate (IBOMA), 23g of bifunctional acrylate active monomer tricyclodecane dimethanol diacrylate (DCPDA), multifunctional The reactive monomer trimethylolpropane triacrylate (TMPTA) 9g of acrylate;

[0041] Photoinitiator, 4.8g of 2-hydroxy-2-methyl-1-phenyl-1-propanone;

[0042] Additives are: adhesion promoter (model: BYK-C8000) 2.6g, defoamer (model: BYK-066N) 0.2g, leveling agent (model: SIVEL 5525) 0.2g, antioxidant ( The model is: hydroquinone) 0.2g, additives 3.2g in total.

[0043] The preparation method of the glass-reinforced UV glue described in this embodiment is prepared as follows: put all the oligomers ...

Embodiment 2

[0046] This example is a colorless and transparent UV light curing control example. This embodiment provides a glass reinforced UV adhesive.

[0047] A glass-reinforced UV adhesive consisting of the following raw materials:

[0048] Oligomer: polyester acrylate 47g;

[0049] Active monomer: 28g of tripropylene glycol diacrylate (TPGDA) active monomer of difunctional acrylate, 19g of active monomer trimethylolpropane triacrylate (TMPTA) of multifunctional acrylate;

[0050] Photoinitiator, 2.8g of 2-hydroxy-2-methyl-1-phenyl-1-propanone;

[0051] The additives are: adhesion promoter (BYK-C8000) 2.6g, defoamer (BYK-066N00.2g, leveling agent (sivel 5525) 0.2g, antioxidant (hydroquinone) 0.2g, additive A total of 3.2g.

[0052] The preparation method of the glass-reinforced UV glue described in this embodiment is prepared as follows: drop all oligomers (polyester acrylate 47g) into the charging kettle, heat to 50°C for preheating; adjust and maintain the temperature as 50 DEG...

Embodiment 3

[0055] This example is a control example of colorless and transparent UV light curing. This embodiment provides a glass reinforced UV adhesive.

[0056] A glass-reinforced UV adhesive consisting of the following raw materials:

[0057] Oligomer: epoxy acrylate 56g;

[0058] Reactive monomer: monofunctional acrylate reactive monomer 2 (2-ethoxyethoxy) ethacrylic acid (EOEOEA) 9g, bifunctional acrylate reactive monomer tricyclodecane dimethanol diacrylate (DCPDA) 19g, active monomer pentaerythritol triacrylate (PET3A) 9g of polyfunctional acrylate;

[0059] Photoinitiator, 2-hydroxy-2-methyl-1-phenyl-1-propanone 4g;

[0060] The additives are: adhesion promoter (BYK-C8000) 2.4g, defoamer (BYK-066N) 0.2g, leveling agent (SIVEL 5525) 0.2g, antioxidant (hydroquinone) 0.2g, auxiliary A total of 3g.

[0061] The preparation method of the glass-reinforced UV glue described in this embodiment is formulated as follows: drop all oligomers (56 g of epoxy acrylate) into the charging k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com