Preparation and release method of a composite inhibitor containing oxidized self-heating temperature-controlled cell coat

A technology of inhibitors and aftercoats, which is applied in mining equipment, earthwork drilling, safety devices, etc., can solve the problems of short inhibitory function time, inability to effectively control spontaneous combustion areas in goafs, and strong fluidity of inhibitors. No toxic and side effects, maintain the inhibitory function for a long time, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

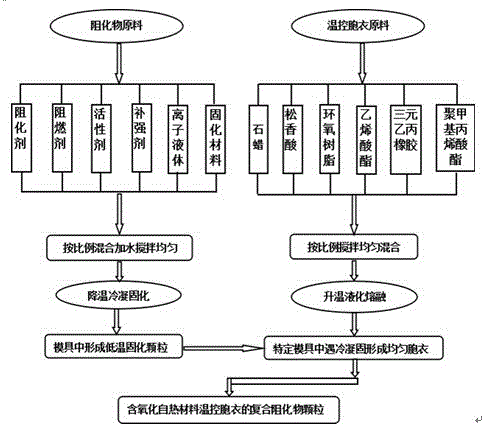

[0034] The preparation method: first, put the inhibitor, flame retardant, active reinforcing agent, functionalized ionic liquid, and solidified material into the container according to the mass ratio, add water in a specified proportion and stir, and wait to mix evenly; secondly , put the composite barrier compound material into the cooling and cooling process to form low-temperature solidified particles in the mold; at the same time, put the organic polymer temperature-controlled aftercoating material into the container in proportion, and stir it until it is evenly mixed and heated to a molten state ; Finally, put the low-temperature cured inhibitor particles into a specific mold containing the polymer temperature-controlled coating material in the molten state, and the temperature-controlled coating material will solidify when cooled, forming a uniform temperature-controlled coating on the surface of the low-temperature inhibitor particles, and finally forming Composite inhib...

Embodiment 1

[0041] Embodiment 1: The inhibitor includes high water-containing composite inhibitor particles and temperature-controlled coating material and preparation method:

[0042] The high-water-containing composite retardant particles include: chemical retardant, flame retardant, active reinforcing agent, functionalized ionic liquid, solidified material and moisture; its mass percentage is: chemical retardant accounts for 35%, flame retardant Accounted for 13%, active reinforcing agent accounted for 8%, functionalized ionic liquid accounted for %, cured material accounted for 6% and water accounted for 28%;

[0043] Described inhibitor is: calcium chloride, magnesium chloride and ammonium chloride;

[0044] Described flame retardant is: magnesium hydroxide;

[0045] The active reinforcing agent is: aliphatic sodium sulfamate and light calcium carbonate;

[0046] The functionalized ionic liquid is: tributylphosphine diethyl phosphate and tributylphosphine methylsulfate;

[0047] T...

Embodiment 2

[0055] Embodiment 2: The inhibitor includes high water-containing composite inhibitor particles and temperature-controlled coating material and preparation method:

[0056] The high-water-containing composite retardant particles include: chemical retardant, flame retardant, active reinforcing agent, functionalized ionic liquid, solidified material and moisture; its mass percentage is: chemical retardant accounts for 30%, flame retardant 10%, active reinforcing agent 5%, functional ionic liquid 5%, curing material 5% and water 25%;

[0057] Described inhibitor is: water glass and sodium percarbonate;

[0058] Described flame retardant is: magnesium hydroxide;

[0059] The active reinforcing agent is: ash calcium powder;

[0060] The functionalized ionic liquid: functionalized 1-acetate ethyl-3-methylimidazolium borate tetrafluoride;

[0061] Described curing material: dicalcium silicate;

[0062] The temperature-controlling coating material consists of piperic acid, epoxy r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com