Glass welded metal vacuum composite insulation board with extraction opening and production method thereof

A technology of air extraction port and heat insulation board, which is applied in the direction of building components, heat preservation, sound insulation, etc., to achieve the effects of low production cost, increased mechanical strength, and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

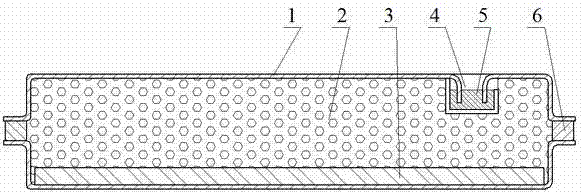

[0032]Referring to the accompanying drawings, the glass-welded metal vacuum composite insulation panel with an air outlet is composed of an outer shell 1, a core material 2 and a core plate 3, the outer shell 1 is composed of a low-carbon steel plate with a thickness of 0.3-1.0mm; the core material 2 is glass fiber, Pearl sand, perlite, vermiculite, aerogel, etc., the core material 1 is preferably dried, packed in a plastic bag, pre-vacuumized, etc.; the core plate 3 is a metal plate, glass plate, ceramic plate or high temperature resistant high polymer Object plate, preferably 3-5mm tempered glass plate or 1-2mm aluminum alloy plate or high-temperature-resistant plastic plate, directly placed in the vacuum chamber; the air extraction port 4 is an air extraction nozzle punched directly from the upper low-carbon steel plate of the shell 1 Composed with a metal cover, low-temperature solder 5 such as tin, zinc, magnesium and low-melting point alloys are placed in the suction nozz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com