Solid phase extraction column for separating different hydrocarbon components in diesel oil and application method

A technology of solid phase extraction column and hydrocarbon components, which is applied in the direction of material separation, analysis materials, measuring devices, etc., can solve the problems of long time-consuming separation of olefins and low recovery rate of olefins, so as to improve separation efficiency and recovery rate of olefins, improve The effect of the detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The above SiO 2 -Al 2 o 3 The preparation method of the stationary phase is as follows: drying silica gel at 100-200°C for 3-8 hours to obtain activated silica gel, and roasting alumina at 300-500°C, preferably 350-450°C for 2-6 hours to obtain activated alumina. Mix the activated silica gel and alumina according to the required ratio to get SiO 2 -Al 2 o 3 Stationary Phase.

[0021] Ag-SiO treated with water 2 The preparation method is as follows: add silver salt solution into silica gel, stir evenly and let it stand for 1-24 hours, preferably 3-10 hours, so that silver ions are evenly adsorbed on the surface of silica gel, and dry at 100-200°C for 1-10 hours to obtain Ag -SiO 2 Stationary Phase. Described silver salt is preferably silver nitrate. Take appropriate amount of Ag-SiO 2 Stationary phase, add water and mix well, let it stand for 12 to 24 hours to get water-treated Ag-SiO 2 .

[0022] The method for separating different hydrocarbon components in ...

example 1

[0037] The silica gel stationary phase and silica gel-alumina stationary phase loaded with silver ions described in the present invention are prepared.

[0038] Dry fine-pore silica gel at 150°C for 5 hours to obtain activated silica gel (SG), which is stored in a desiccator for later use. Activated alumina (SAL) was obtained by calcining neutral alumina at 400°C for 4 hours. Weigh SG and SAL in proportion, mix them evenly, and prepare a certain mass fraction of silica gel-alumina stationary phase. Put in a desiccator for later use.

[0039] Take 3g of silver nitrate and dissolve it in 50g of water to make a solution, take 50g of silica gel, add the silica gel to the silver nitrate solution while stirring, after stirring evenly, let it stand for 5 hours, and dry at 150°C for 5 hours to obtain a silver solution with a silver content of 3.8% by mass. Ag-SiO 2 stationary phase (ASG). Take out a part and weigh the mass accurately, add a certain weight of distilled water, shake...

example 2

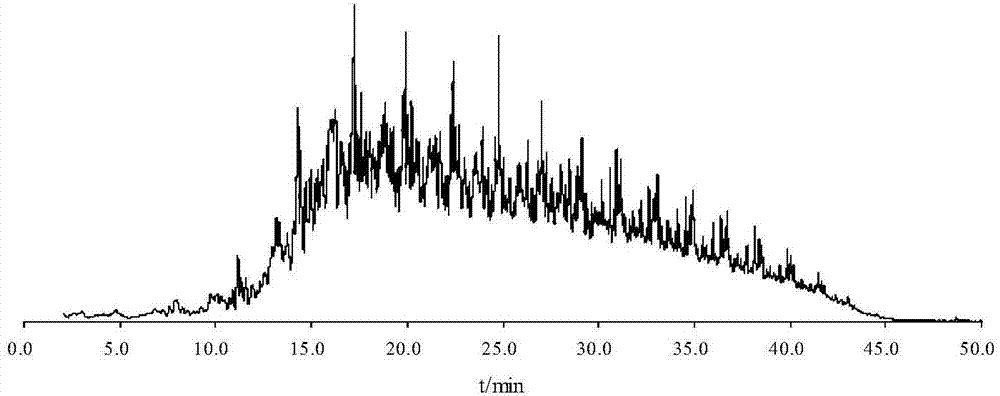

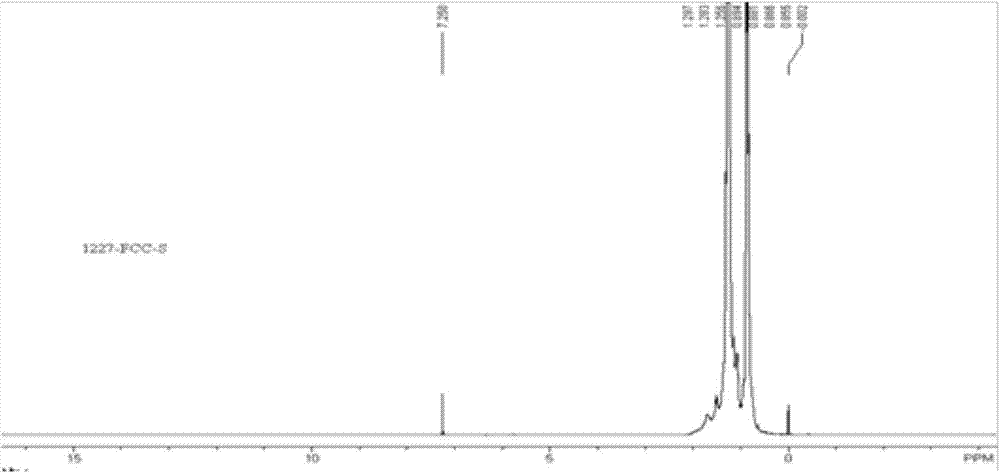

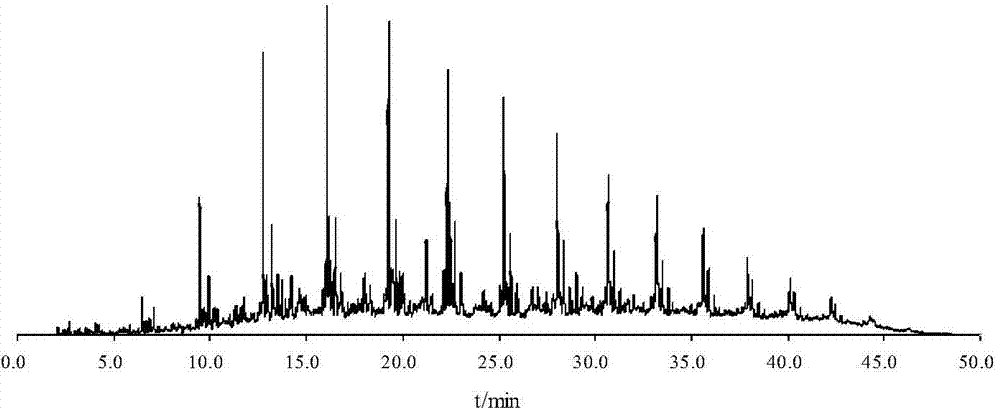

[0041] The aromatic hydrocarbons, olefins and saturated hydrocarbons in the catalytic cracking diesel oil are separated by the solid phase extraction method of the present invention.

[0042] The upper column of the solid phase extraction column is filled with 1.5g of silica gel-alumina stationary phase with an alumina content of 15% by mass, and the lower column is filled with 1.5g of Ag-SiO with a water content of 8% by mass. 2 Stationary phase (ASG-1). Moisten with 1.5 mL of n-pentane, respectively.

[0043] Take 60 μL of catalytically cracked diesel oil with a distillation range of 180-350°C and add it to the column. Use 3 mL of n-pentane to wash the saturated hydrocarbon and olefin components to the lower column, and then separate the two columns. The upper column was washed with 4 mL of dichloromethane-ethanol solution with a volume ratio of 5:1 to obtain an aromatic hydrocarbon solution. The lower column was washed with 2 mL of n-pentane to obtain a saturated hydroca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com