Cobaltosic oxide and cobalt molybdate core-shell heterostructure nanowire array, preparation method and application thereof

A technology of cobalt trioxide nanometer and cobalt trioxide, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low energy density and power density, difficult to meet application requirements, small active area, etc. Achieve the effects of high energy density and power density, good crystal shape, and large specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

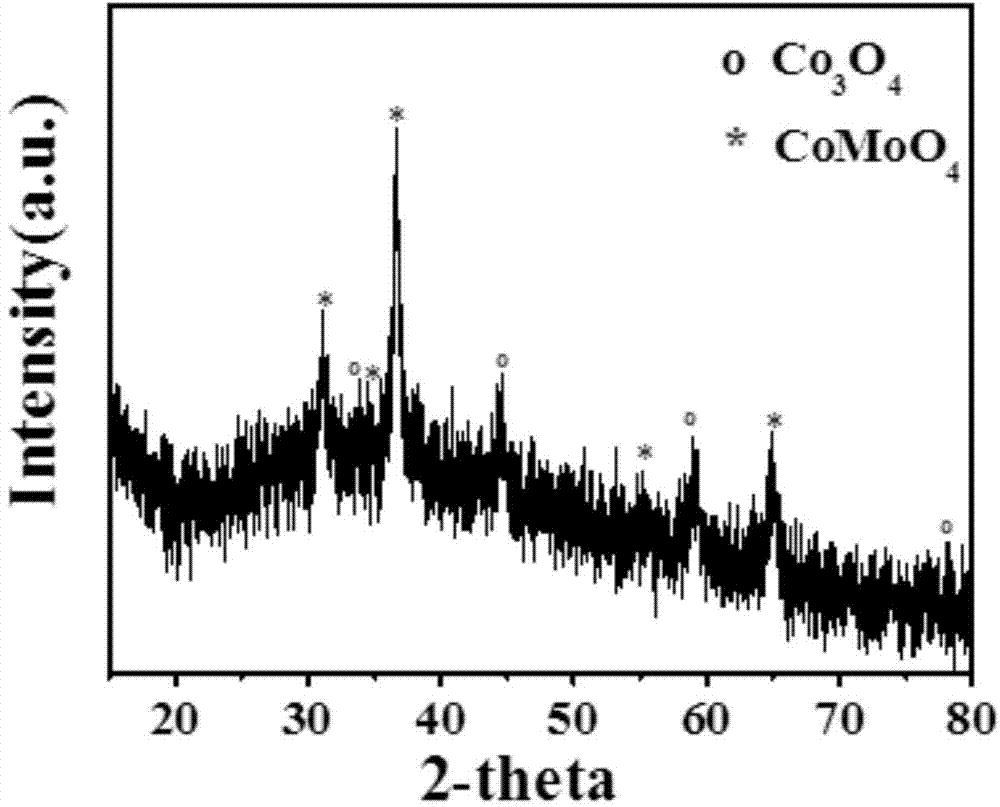

[0034] A preparation method of tricobalt tetroxide and cobalt molybdate core-shell heterostructure nanowire array, comprising the following steps:

[0035] a. Put the nickel foam with impurities on the surface into dilute hydrochloric acid, ethanol, and double distilled water in turn for ultrasonic cleaning for 20 minutes;

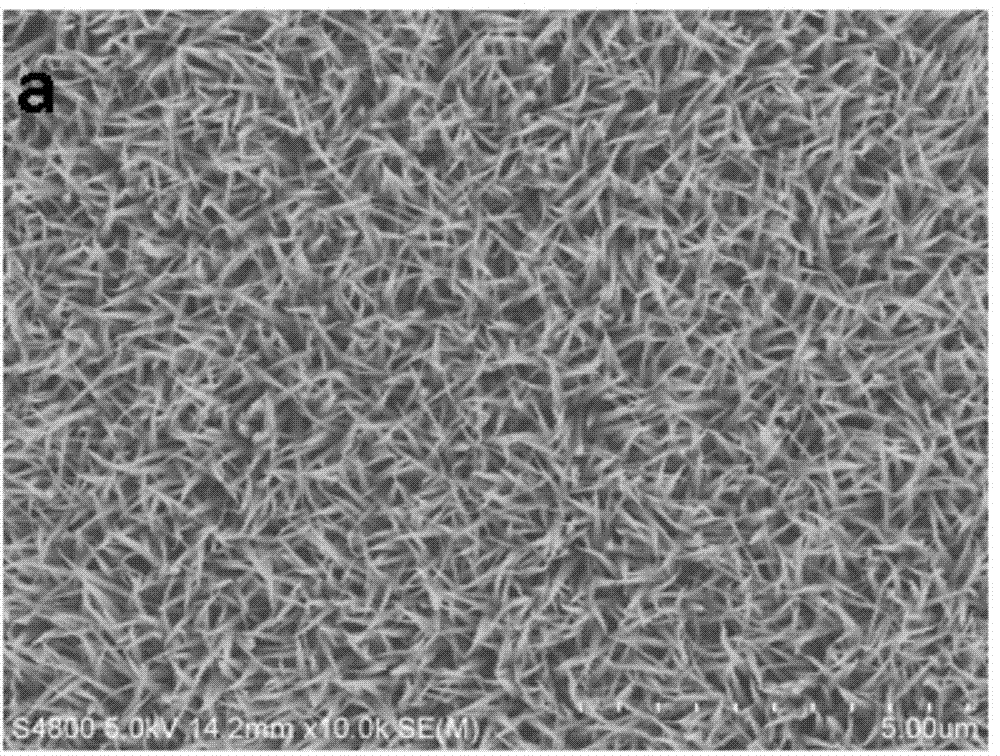

[0036] b. Mix 40mL double-distilled water, 2mmol cobalt chloride hexahydrate, 4mmol ammonium fluoride and 10mmol urea evenly and add them into a 60mL reaction kettle, immerse the treated foamed nickel into the mixture, pour it into the reaction kettle, and tighten the kettle Cover, react at 100°C for 8 hours, take out the reactor and cool it down to room temperature naturally, rinse with ethanol and double distilled water successively, dry at room temperature, and calcinate at 400°C for 3 hours in an air atmosphere to prepare cobalt trioxide nanowire materials.

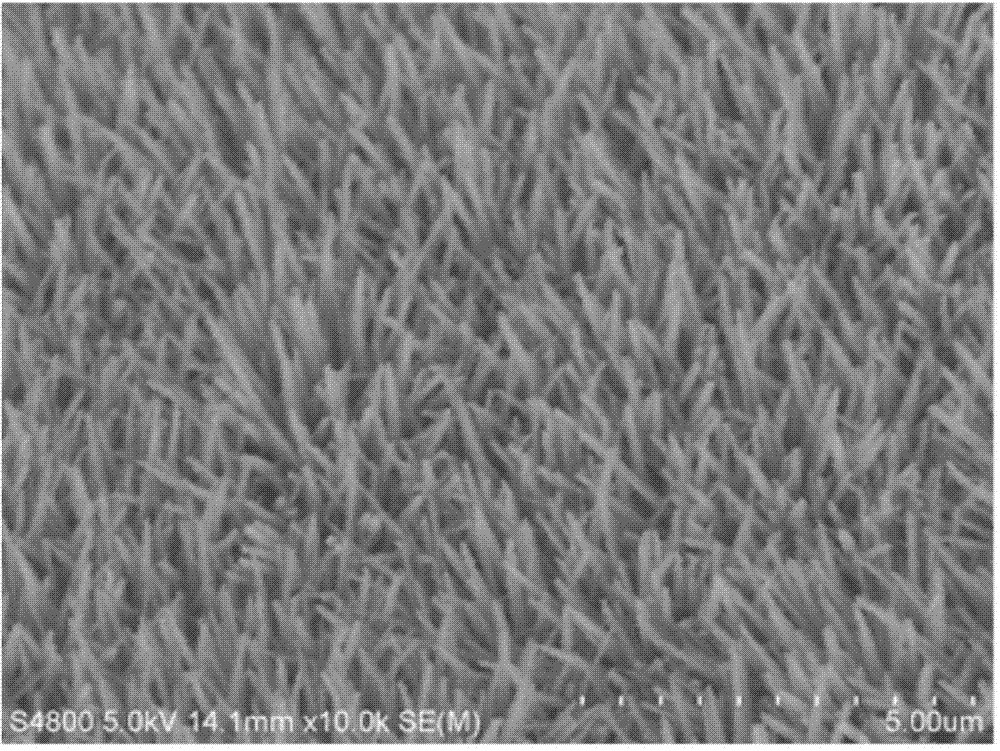

[0037] c. Dissolve 1mmol sodium molybdate dihydrate and 10mmol urea in 40mL double-distilled w...

Embodiment 2

[0043] A preparation method of tricobalt tetroxide and cobalt molybdate core-shell heterostructure nanowire array, comprising the following steps:

[0044] a. Put the nickel foam with impurities on the surface into dilute hydrochloric acid, ethanol, and double distilled water in turn for ultrasonic cleaning for 20 minutes;

[0045] b. Mix 40mL double-distilled water, 2mmol cobalt chloride hexahydrate, 4mmol ammonium fluoride and 10mmol urea evenly and add them into a 60mL reaction kettle, immerse the treated foamed nickel into the mixture, pour it into the reaction kettle, and tighten the kettle Cover, react at 100°C for 8 hours, take out the reactor and cool it down to room temperature naturally, rinse with ethanol and double distilled water successively, dry at room temperature, and calcinate at 400°C for 3 hours in an air atmosphere to prepare cobalt trioxide nanowire materials.

[0046] c. Dissolve 1mmol sodium molybdate dihydrate and 10mmol urea in 40mL double-distilled w...

Embodiment 3

[0049] A preparation method of tricobalt tetroxide and cobalt molybdate core-shell heterostructure nanowire array, comprising the following steps:

[0050] a. Put the nickel foam with impurities on the surface into dilute hydrochloric acid, ethanol, and double distilled water in turn for ultrasonic cleaning for 20 minutes;

[0051] b. Mix 40mL double-distilled water, 2mmol cobalt chloride hexahydrate, 4mmol ammonium fluoride and 10mmol urea evenly and add them into a 60mL reaction kettle, immerse the treated foamed nickel into the mixture, pour it into the reaction kettle, and tighten the kettle Cover, react at 100°C for 8 hours, take out the reactor and cool it down to room temperature naturally, rinse with ethanol and double distilled water successively, dry at room temperature, and calcinate at 300°C for 3 hours in an air atmosphere to prepare the cobalt trioxide nanowire material.

[0052] c. Dissolve 1mmol sodium molybdate dihydrate and 10mmol urea in 40mL double-distille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com