Method and device for pattering nano carbon material film

A material thin film, nano-carbon technology, applied in nanotechnology, electrical components, circuits, etc., can solve problems such as complex processes and easy pollution, and achieve the effects of broad application prospects, short processing time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

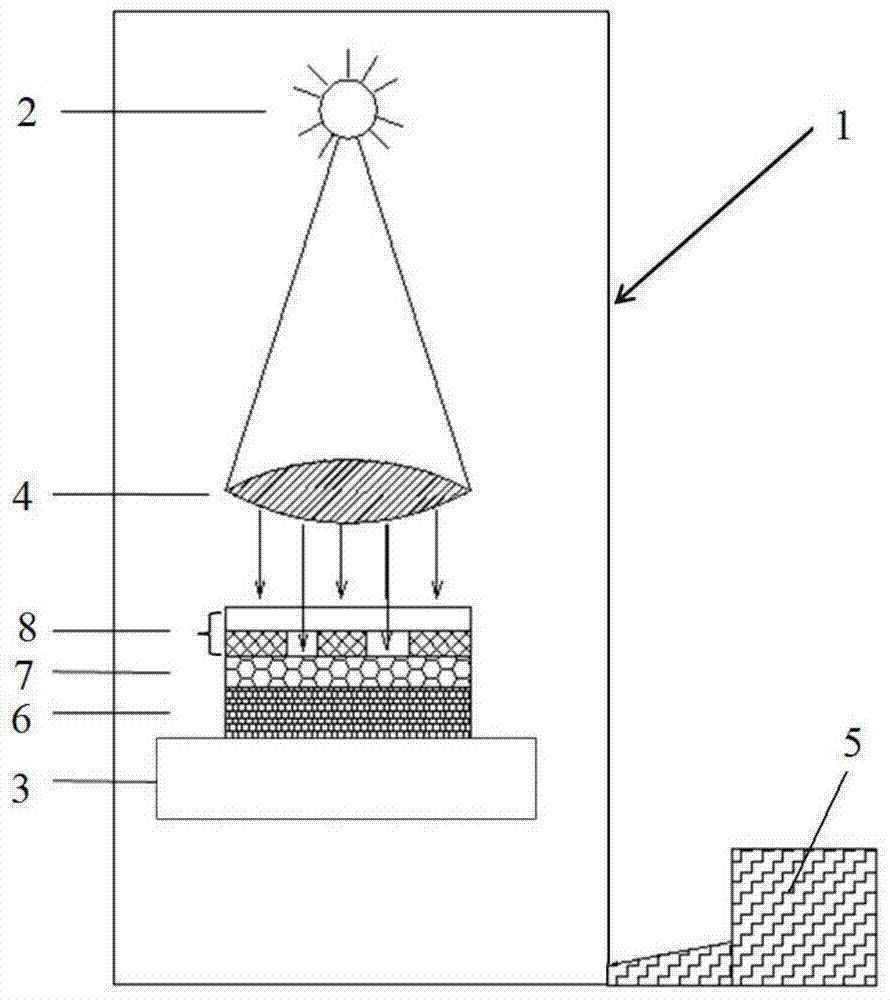

[0034] This embodiment provides a device for patterning nano-carbon material thin films, such as figure 1 As shown, it includes a closed working chamber 1, and the working chamber 1 is provided with an ultraviolet light source 2 and an operating table 3. The ultraviolet light source 2 is used to emit ultraviolet light with a wavelength band of 10-240nm and a wavelength band of 240-400nm. The operating table 3 is used for placing the nano-carbon material film 7 to be etched.

[0035] In this embodiment, an optical path collimation device 4 for optical path collimation is also arranged in the working chamber 1 , and the ultraviolet light is irradiated on the operation table 3 through the optical path collimation device 4 . The working chamber 1 is also connected with an ozone generator 5 , and the ozone generator 5 injects ozone into the sealed working chamber 1 .

[0036] The optical path collimation device 4 is similar to the exposure machine, and is selected from but not lim...

Embodiment 2

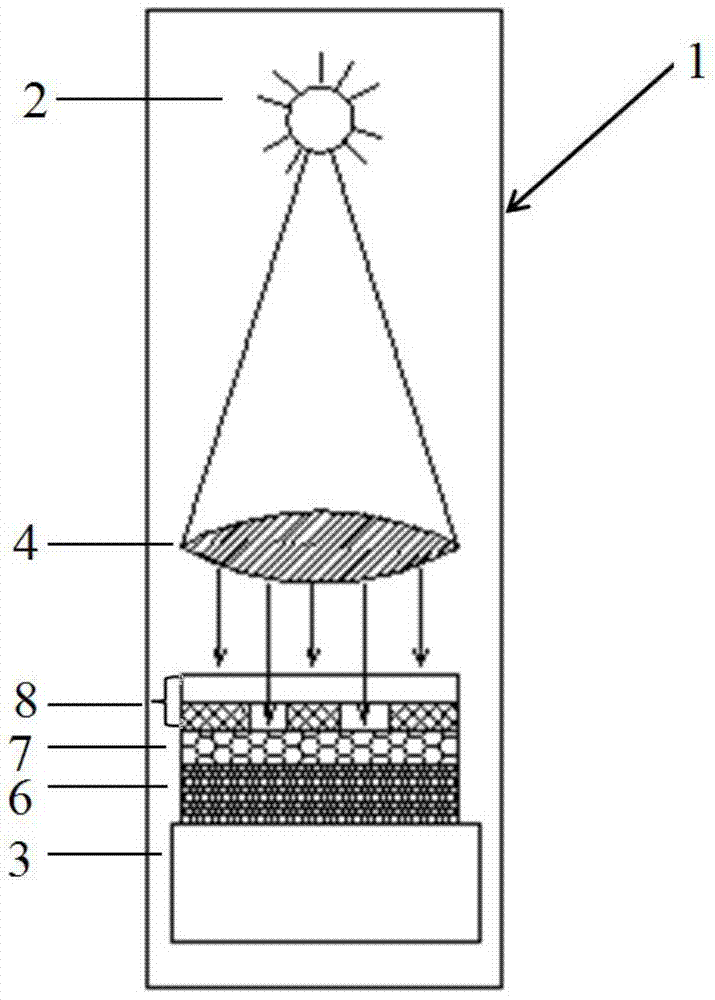

[0051] This embodiment provides a device for patterning nano-carbon material thin films, such as figure 2 As shown, the structure is the same as in Embodiment 1, except that the ozone generator 5 is not provided.

Embodiment 3

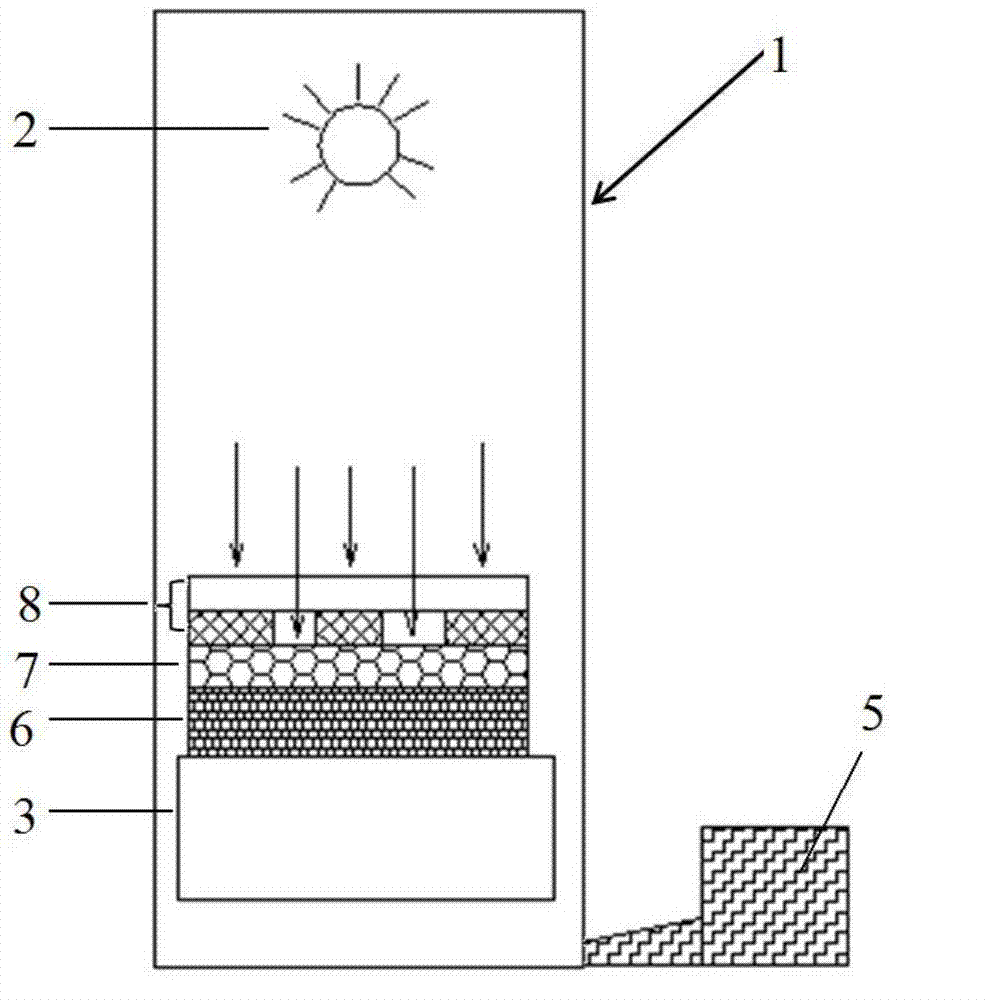

[0053] This embodiment provides a device for patterning nano-carbon material thin films, such as image 3 As shown, the structure is the same as that of Embodiment 1, except that the optical path collimation device 4 is not provided.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com