MnOx/graphene low-temperature SCR flue gas denitration catalyst, preparation method and applications thereof

A denitrification catalyst and graphene technology, which is applied in the field of environmental protection and environmental catalysis, can solve the problems of wasting energy consumption and achieve reasonable cost, excellent low-temperature SCR flue gas denitrification performance, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

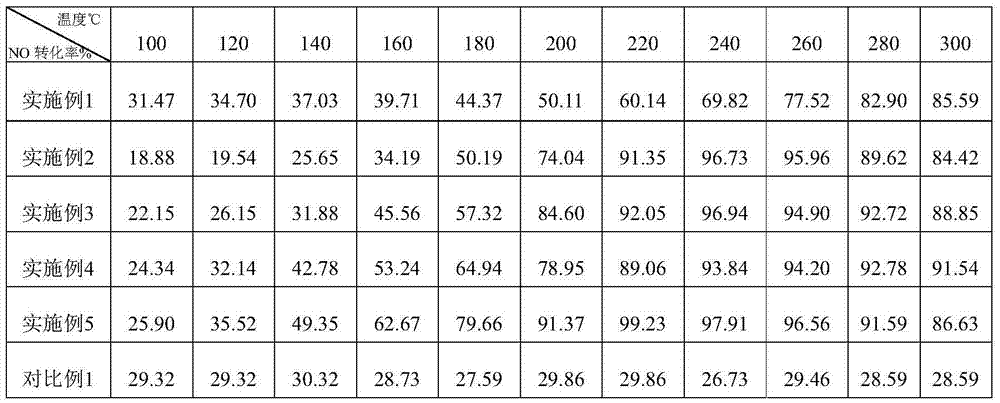

Examples

Embodiment 1

[0030] (1) Preparation of graphene oxide: disperse the prepared graphite oxide into deionized water, and obtain a graphene oxide suspension with a concentration of 2.0 mg / ml after ultrasonication for 120 min;

[0031] (2) Water bath heating reaction: dissolve 1.0 mmol of manganese acetate in 10 ml of deionized water and slowly add it dropwise to the above graphene oxide suspension with a rubber dropper, stir at room temperature for 20 min, and react in a water bath at 80 ° C for 5 h After the reaction, add ammonia water dropwise to the solution, adjust the pH of the solution to 10, and continue to stir for 30 minutes;

[0032] (3) Hydrothermal synthesis reaction: transfer the reacted solution in step (2) to a reactor for hydrothermal reaction at 120°C for 12 hours. After the reaction is completed, filter the solution and wash it with a large amount of deionized water. The filter cake was dried in a blast drying oven at 60°C for 12 hours;

[0033] (4) Activation: The sample ob...

Embodiment 2

[0035] (1) Preparation of graphene oxide: disperse the prepared graphite oxide into deionized water, and obtain a graphene oxide suspension with a concentration of 2.0 mg / ml after ultrasonication for 120 min;

[0036] (2) Water-bath heating reaction: dissolve 2.0 mmol of manganese acetate in 10 ml of deionized water and slowly add it dropwise to the above graphene oxide suspension with a rubber dropper, stir at room temperature for 20 min, and react in a water bath at 80 °C for 4 h After the reaction, add ammonia water dropwise to the solution, adjust the pH of the solution to 10, and continue to stir for 30 minutes;

[0037] (3) Hydrothermal synthesis reaction: transfer the solution after the reaction in step (2) to a 200ml reactor and place it in an oven for hydrothermal reaction at 140°C for 12 hours. After the reaction is completed, filter the solution, and use a large amount of deionized water After washing, place the filtered filter cake in a blast drying oven at 60°C fo...

Embodiment 3

[0040] (1) Preparation of graphene oxide: disperse the prepared graphite oxide into deionized water, and obtain a graphene oxide suspension with a concentration of 2.0 mg / ml after ultrasonication for 120 min;

[0041](2) Water-bath heating reaction: dissolve 3.0 mmol of manganese acetate in 10 ml of deionized water and slowly add it dropwise to the above graphene oxide suspension with a rubber dropper, stir at room temperature for 20 min, and react in a water bath at 80 °C for 3 h After the reaction, add ammonia water dropwise to the solution to adjust the pH of the solution to 10, and continue to stir for 30 minutes;

[0042] (3) Hydrothermal synthesis reaction: transfer the reacted solution in step (2) to the reaction kettle for hydrothermal reaction at 160°C for 12 hours, filter the solution after the reaction is completed, and wash with a large amount of deionized water, and the filtered The filter cake was dried in a blast drying oven at 60°C for 12 hours;

[0043] (4) A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com