Method and equipment for evaporation crystallization of high concentration salt water

A technology for evaporative crystallization and concentrated brine, which is applied in chemical instruments and methods, water/sewage treatment, heating water/sewage treatment, etc. Large land and other problems, to achieve the effect of low power consumption, low construction cost and long running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

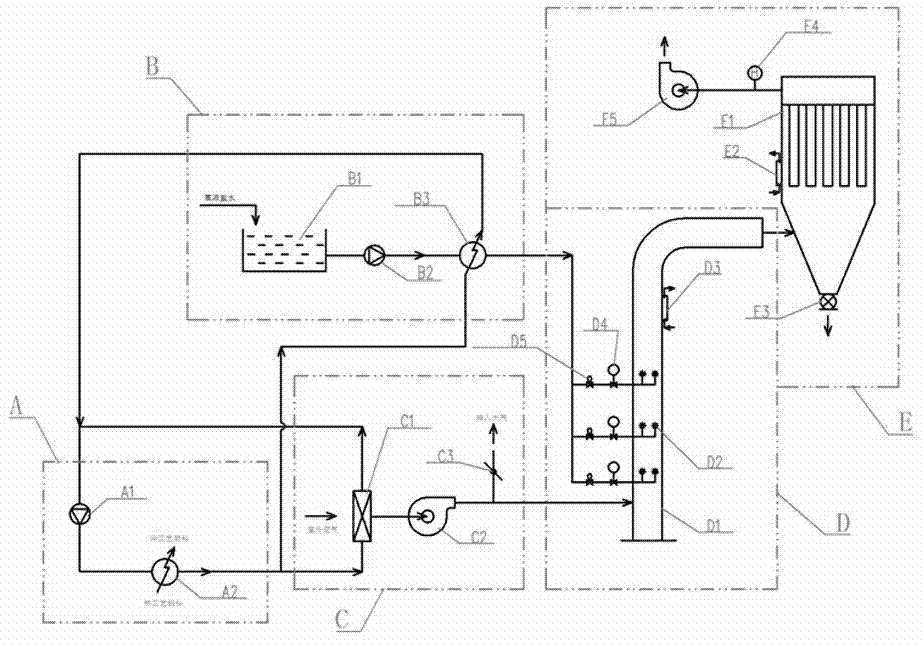

[0024] like figure 1 As shown, a method for evaporative crystallization of high-concentration brine is characterized in that: comprising the following steps:

[0025] (1) Collect the waste heat of low-temperature materials to prepare low-temperature hot water below 95°C;

[0026] (2) Heat high-concentration brine and air separately with low-temperature hot water;

[0027] (3) Atomize the heated high-concentration brine and mix it with heated air to form salt particles;

[0028] (4) Separate the salt particles from the air, collect the salt particles, and discharge the air into the atmosphere to achieve the goal of zero emissions.

[0029] The equipment for evaporating and crystallizing high-concentrated brine of the present invention includes a low-temperature heat recovery device A, a concentrated brine pressurization device B, an air heating device C, an evaporation crystallization device D, and a dust removal device E. The low-temperature heat recovery device A recovers t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com