A special slow and controlled release formula fertilizer for citrus crops and its preparation and application method

An application method and a technology of formula fertilizer, applied in the direction of fertilization method, application, fertilization device, etc., can solve the problems of not being able to meet the comprehensive nutrient needs of citrus crops in red soil areas, the number of fertilization times, and the high cost of manpower and material resources, so as to overcome the ability of fertilizer storage poor, high nutrient use efficiency, and the effect of increasing nitrogen use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

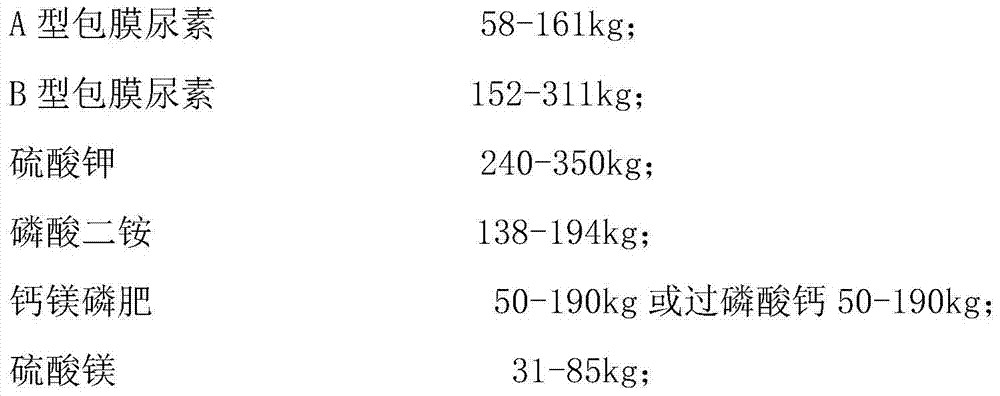

[0050] The special slow and controlled release formula fertilizer for citrus crops provided in this example first weighed

[0051] 13% sulfur-coated type A coated urea 54kg; 9% resin-coated type B coated urea 161kg; potassium sulfate 240kg; diammonium phosphate 179kg; calcium magnesium phosphate fertilizer 190kg; magnesium sulfate 31kg; borax 10kg; zinc sulfate 10kg ; Synergist 10kg; Bentonite 115kg. Then the above-mentioned raw materials are put into a mixer and stirred until completely mixed uniformly, thereby preparing the formula fertilizer containing 12% nitrogen, 12% phosphorus pentoxide, 12% potassium oxide, and 4.0% calcium as a percentage of the total mass of the formula fertilizer. 1.4% magnesium, 4.8% sulfur, 0.11% boron, 0.22% zinc, 1.0% synergist and a slow and controlled release formula fertilizer with a total mass of 1 ton.

[0052] In this example, Type A coated urea is prepared by fluidized bed coating method by using commercially available urea and sulfur at...

Embodiment 2

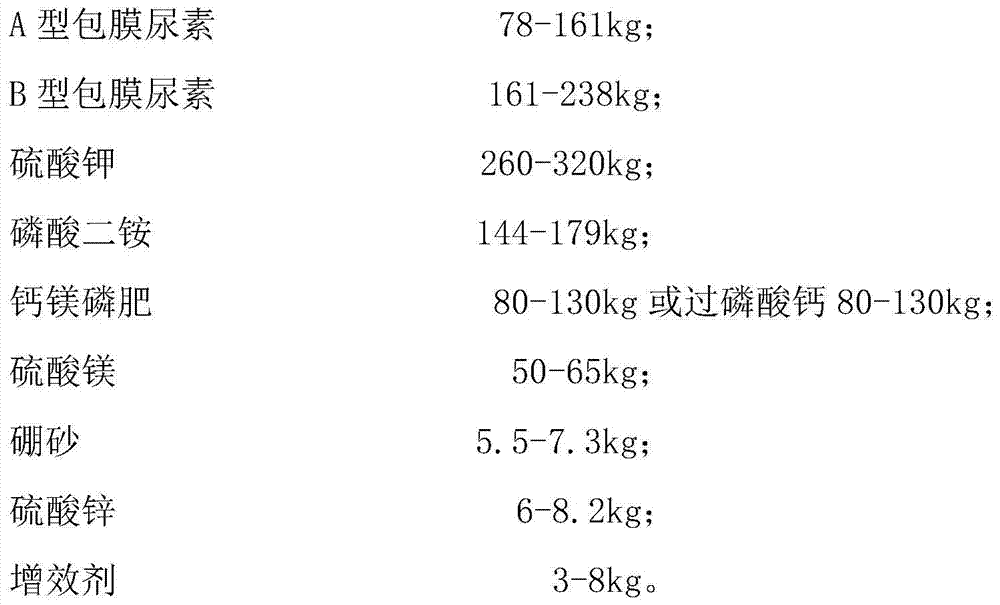

[0054] The special slow and controlled release formula fertilizer for citrus crops provided in this example first weighed

[0055] 4% resin-coated type A coated urea 194kg; 10% resin-coated type B coated urea 238kg; potassium sulfate 320kg; diammonium phosphate 144kg; superphosphate 50kg; magnesium sulfate 31kg; borax 4.5kg; zinc sulfate 5kg; synergist 2kg; attapulgite 11.5kg. Then the above-mentioned raw materials are put into a mixer and stirred until they are completely mixed, thereby preparing the formula fertilizer containing 20% nitrogen, 8% phosphorus pentoxide, 16% potassium oxide, and 1.0% calcium as a percentage of the total mass of the formula fertilizer. 0.3% magnesium, 6.7% sulfur, 0.05% boron, 0.11% zinc, 0.2% synergist, and a slow and controlled release formula fertilizer with a total mass of 1 ton.

[0056] In this example, type A coated urea is prepared by drum method using commercially available urea and resin at a mass ratio of 96:4; type B coated urea is...

Embodiment 3

[0058] The special slow and controlled release formula fertilizer for citrus crops provided in this example first weighed

[0059] 4% resin-coated type A coated urea 101kg, 10% resin-coated type B coated urea 152kg; potassium sulfate 360kg; diammonium phosphate 99kg; superphosphate 190kg; magnesium sulfate 50kg; borax 7.3kg; zinc sulfate 8.2kg; synergist 8kg; attapulgite 24.5kg. Then above-mentioned raw material is put into stirrer and stirs, until completely mix uniformly, thereby prepares and accounts for the percentage of described formula fertilizer total mass and contains nitrogen 12%, phosphorus pentoxide 8%, potassium oxide 18%, calcium 4.0%, 0.5% magnesium, 9.2% sulfur, 0.08% boron, 0.18% zinc, 0.8% synergist, and a slow and controlled release formula fertilizer with a total mass of 1 ton.

[0060] In this example, type A coated urea is prepared by disc spray coating method by using commercially available urea and resin at a mass ratio of 96:4; type B coated urea is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com