Method for coproduction of dicumyl peroxide (DCP) and epoxybutane (CHPBO)

A technology of dicumyl peroxide and butylene oxide, applied in the preparation of peroxy compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of consumption of reducing agent and hydrogen, low CHP conversion rate, BO selection In order to achieve the effect of reducing waste water discharge treatment, shortening process flow and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

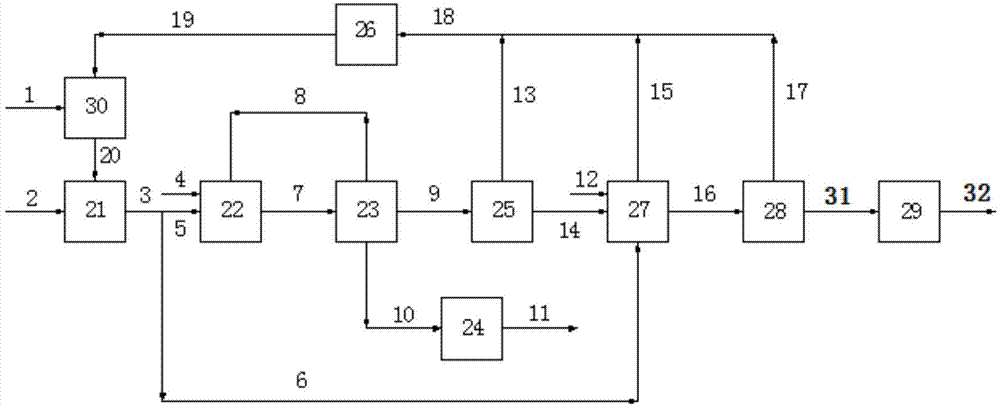

[0022] in such as figure 1 In the shown process flow, the fresh raw material cumene (1) and the recycled cumene (19) reclaimed by the combined unit enter the alkali cleaning device (30) for alkali cleaning, and the cumene (20) and air after the alkali cleaning (2) gas-liquid two-phase oxidation reaction occurs in the cumene oxidation unit (21), generates CHP oxidation liquid (3), wherein a part of CHP oxidation liquid (5) enters the epoxidation reaction unit (22) of the BO device and Butene (4) undergoes an epoxidation reaction, and the epoxidation reaction product (7) enters the butene and BO separation unit (23), and the separated butene (8) returns to the epoxidation reaction unit (22) for recycling . From the thick dimethyl benzyl alcohol (9) flowing from butene and BO separation unit (23), the dimethyl benzyl alcohol rectification unit (25) of the DCP device separates the refined dimethyl benzyl alcohol (14) and Cumene (13). Refined dimethyl benzyl alcohol (14) enters ...

Embodiment 2

[0025] According to the conditions described in Example 1, only the production scale of the DCP industrial plant was changed to 1000 tons / year. As a result, the CHP conversion rate reaches 99.6%, and the BO selectivity reaches 99.1%. While producing 1,000 tons / year of DCP products, 266.7 tons / year of BO products are co-produced, and materials such as cumene, CHP and DMCA are recycled without vulcanization. The consumption of reducing agent and hydrogen raw material and the discharge of sulfur-containing wastewater.

Embodiment 3

[0027] According to the conditions described in Example 1, only the production scale of the DCP industrial plant was changed to 10,000 tons / year. As a result, the conversion rate of CHP reaches 99.7%, and the selectivity of BO reaches 99.2%. While producing 10,000 tons / year of DCP products, 2,666.7 tons / year of BO products are co-produced, and materials such as cumene, CHP and DMCA are recycled, and there is no Consumption of sulfide reducing agent and hydrogen feedstock and discharge of sulfur-containing wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com