Method for forming epitaxial silicon layer

A silicon layer, vapor phase epitaxy technology, applied in chemical instruments and methods, coatings, metal material coating processes, etc., can solve problems such as unfavorable material yield, no grain size, etc., to reduce auxiliary heating requirements, high Energy conversion yield, effect of increasing material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

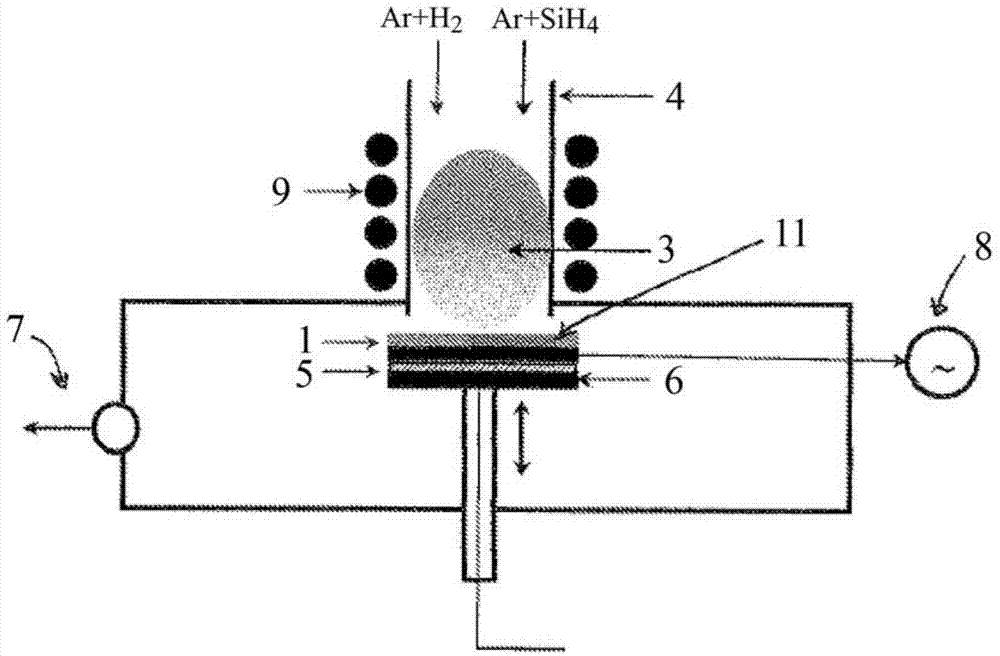

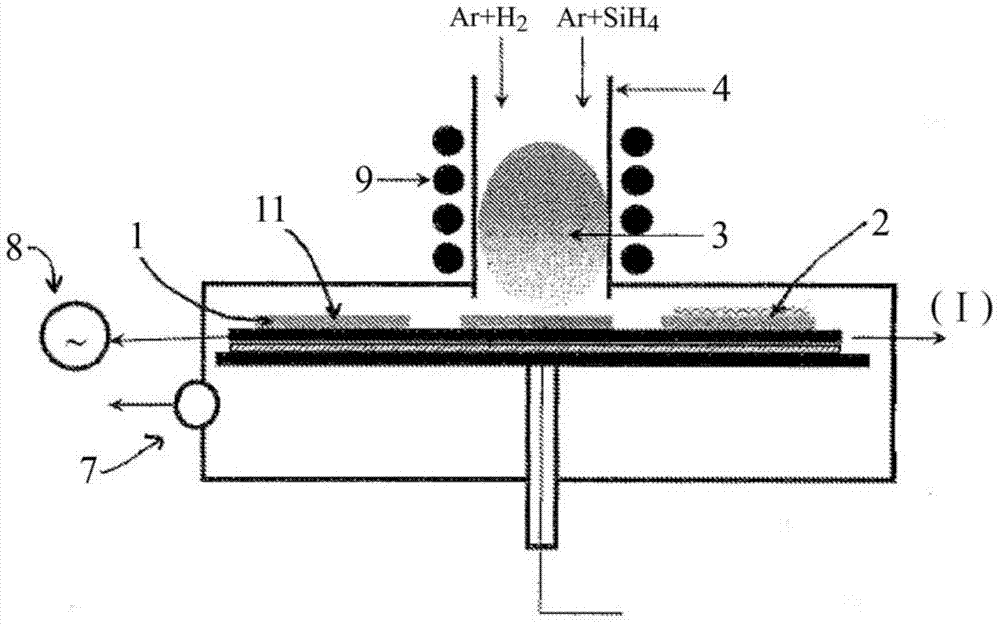

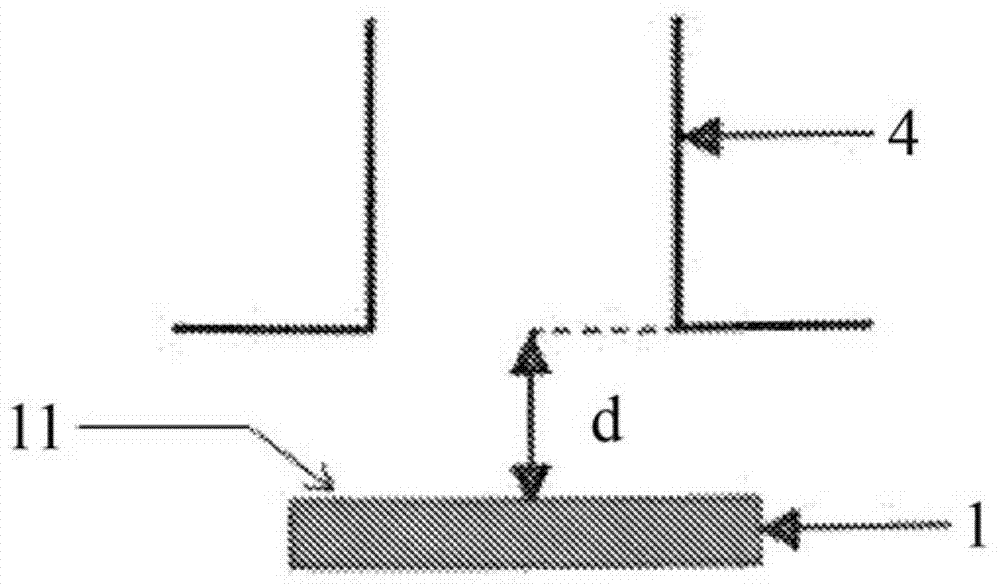

[0123] The thin silicon layers were obtained with an experimental setup consisting of a water-cooled stainless steel chamber, a cold cage plasma torch 4, and a substrate holder also water-cooled.

[0124] ( i) UMG silicon substrate

[0125] Substrate 1 is a UMG silicon substrate with a thickness of 400 μm and an average grain size of 8 mm. It includes metallic impurities at a level of 500ppb, boron at a level of 30ppm, and phosphorus at a level of 10ppm.

[0126] (ii) Thermal plasma chemical vapor deposition

[0127] The UMG silicon substrate was placed on a substrate holder equipped with a graphite resistance heating device 6 in order to reach a temperature of about 1100°C. The temperature is controlled using a thermocouple coupled to the generator.

[0128] The pressure of the chamber is reduced to 1 mbar by means of a suction device 7 . At this pressure, a plasma discharge was initiated by a radio frequency generator operating at a frequency of 4 MHz and a power of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com