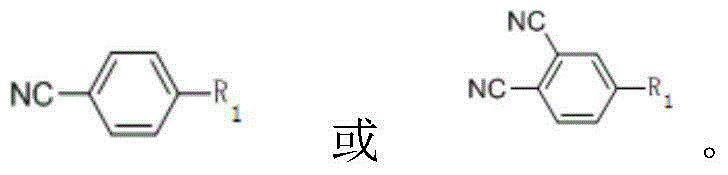

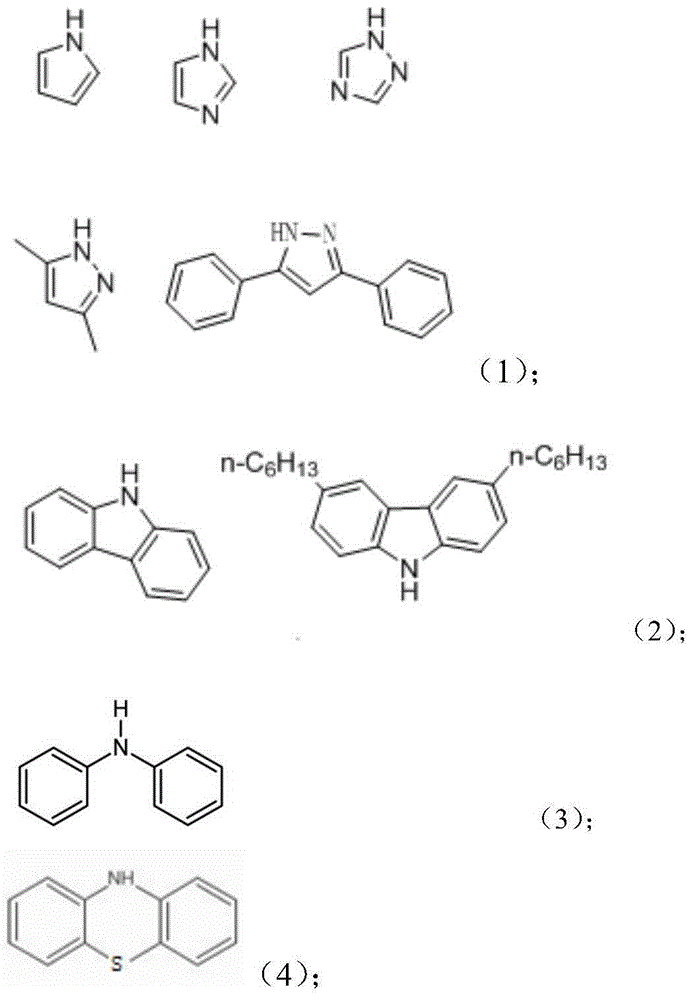

Synthetic method of nitrogen heterocyclic ring cyanophenyl or phthalonitrile compound

A nitrogen heterocyclic compound and a synthesis method technology are applied in the field of synthesis of nitrogen-containing heterocyclic benzonitrile or phthalonitrile compounds, can solve the problems of unsuitability for scale-up production, harsh synthesis conditions, expensive catalysts, etc., and achieve low cost, Easy-to-obtain, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The synthesis of 4-(1 hydrogen-pyrrol-1-yl) benzonitrile, concrete steps are as follows:

[0027] Add 0.11mol (7.5g) of pyrrole, 0.1mol (12.1g) of 4-fluorobenzonitrile, 0.16mol (22.1g) of potassium carbonate and 100ml of THF into a 250ml round-bottomed flask, replace with nitrogen 3 times, and place in an oil bath The pot was heated to reflux for 5h. Cool to room temperature, pour into 500ml of ice water, filter with suction, and dry in the air. Petroleum ether: ethyl acetate volume ratio = 20:1 was used as the developer to pass through the flash column to obtain 14.3 g of white powder with a yield of 85%. Proton NMR data of the target product: 1 H NMR (CDCl 3 ,400MHz), (TMS,ppm):7.78(m,2H),7.57-7.40(m,2H),7.13(s,1H),6.40(s,2H).

Embodiment 2

[0029] The synthesis of 4-dianiline benzonitrile, concrete steps are as follows:

[0030] Add 55mmol (9.31g) of diphenylamine, 50mmol (6.05g) of 4-fluorobenzonitrile, and 70ml of DMF into a 150ml round bottom flask, lower it to 0°C, and add 75mmol (1.8g) of NaH to the above system in 5 batches In the process, the time interval between each batch is 20min. After the addition, the system is warmed up to 80°C and stirred overnight. The system was cooled to room temperature, then poured into about 250ml of ice water, filtered with suction, and dried in the air. Petroleum ether: ethyl acetate volume ratio = 30:1 was used as the developer to pass through the flash column, and finally the target product was light yellow solid powder, 10.3g, with a yield of 76.3%. Proton NMR data of the target product: 1 H NMR (CDCl 3 ,400MHz), (TMS,ppm):7.42(d,2H),7.34(t,4H),7.16(m,6H),6.96(d,2H).

Embodiment 3

[0032] For the synthesis of 4-(2(4-methoxyphenyl)amino)benzonitrile, the specific steps are the same as in Example 2. Substrate: 14.3mmol (4.72g) bis(4-methoxyphenyl)amine, 13mmol (1.57g) 4-fluorobenzonitrile, 20mmol (0.48g) NaH, DMF 60ml. Petroleum ether: ethyl acetate volume ratio = 30:1 was used as a developer to pass through the column to obtain 3.1 g of white solid powder with a yield of 71.9%. The proton NMR data of the target product are: 1 H NMR (CDCl 3 ,400MHz), (TMS,ppm):7.37(d,2H),7.12(d,4H),6.90(d,4H),6.81(d,2H),3.83(s,6H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com