Preparation method of oil-extended oxygenated graphene solution co-coagulation rubber

An oil-filled, oxygen-filled, and gelatinized rubber technology is applied in the field of polymer-based nanocomposite materials, which can solve the problems of uneven dispersion, flying dust, and poor composite material performance, and achieve excellent antistatic performance, strong operability, and ease of use. effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

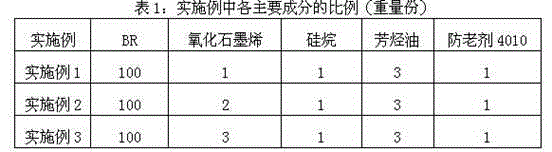

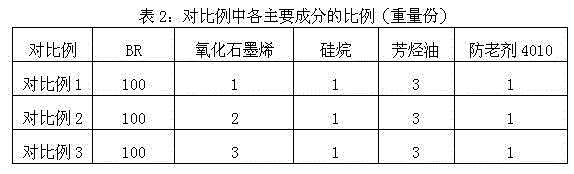

[0019] Examples 1-3: Taking aromatic hydrocarbon oil-filled graphene oxide solution co-coagulated butadiene rubber as an example, the preparation method and properties of oil-filled graphene oxide solution co-coagulated rubber of the present invention are illustrated.

[0020] (1) Preparation of graphene oxide: add graphite to sulfuric acid with a concentration of 98%, stir for 20 minutes, then add potassium permanganate, control the reaction temperature to less than 10°C and stir in a water bath for 3 hours. Add a certain amount of deionized water to the reaction system for dilution, and continue stirring in a water bath. 20% hydrogen peroxide was added to the system, and after 15 minutes of ultrasonic stripping, centrifugation, washing and drying, graphene oxide was prepared.

[0021] (2) Preparation of oil-filled graphene oxide solution co-coagulated rubber: add graphene oxide, oil, coupling agent, and anti-aging agent to the butadiene rubber solution in a certain ratio, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com