Preparation method of fucoxanthol

A technology of fucoxanthin and fucoxanthin is applied in the field of preparation of high-purity fucoxanthin, and can solve the problems of high-value development and application of fucoxanthin series products that cannot be fucoxanthin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

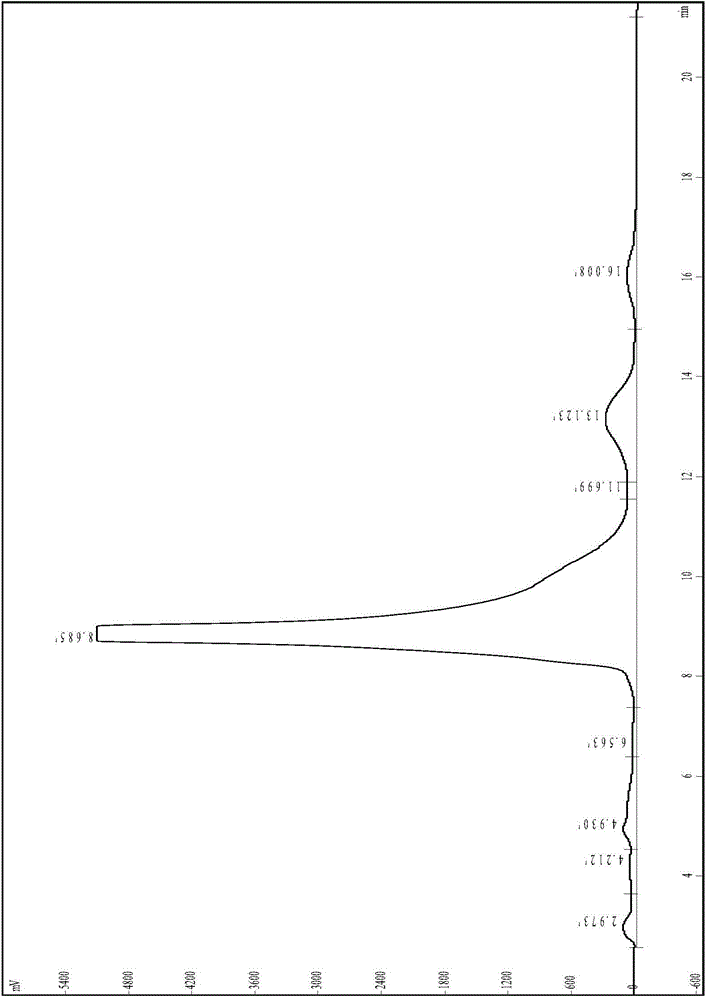

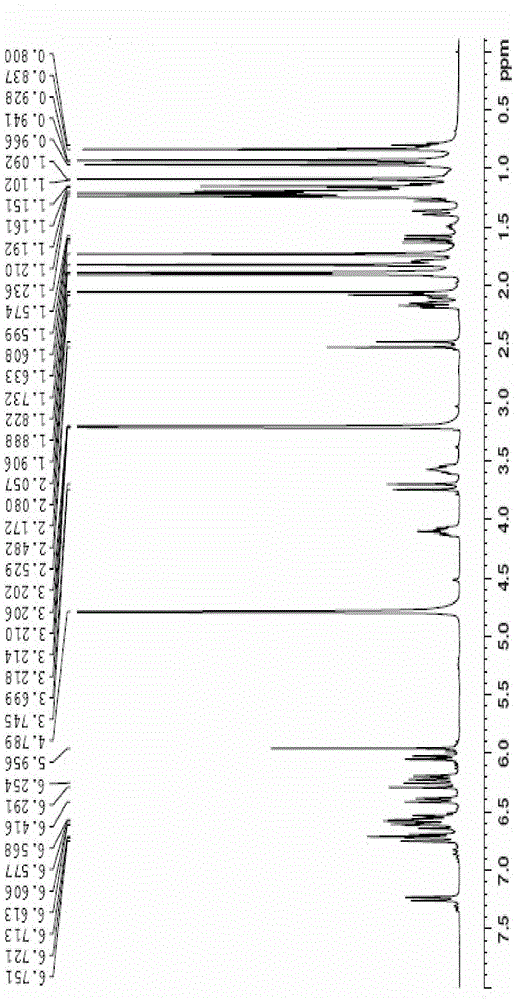

[0034] 1) Enzymolysis reaction: Take 50 mg of fucoxanthin (purity: 99%), add 50 mg of lipase, 50 mg of sodium taurocholate, dissolve in 0.1M PBS buffer solution with pH=3, and react at 20°C for 1 hour Afterwards, concentrate to dryness, add 50mL of methanol for ultrasonic extraction, filter, and concentrate the filtrate to dryness to obtain 55 mg of fucoxanthol reactant, and the conversion rate of fucoxanthol is 23%;

[0035] 2) Fucoxanthol refining:

[0036] a) Configuration of raw materials: the crude product of fucoxanthin is configured into a 6 mg / mL solution;

[0037] b) Instrument: semi-preparative high performance liquid chromatography;

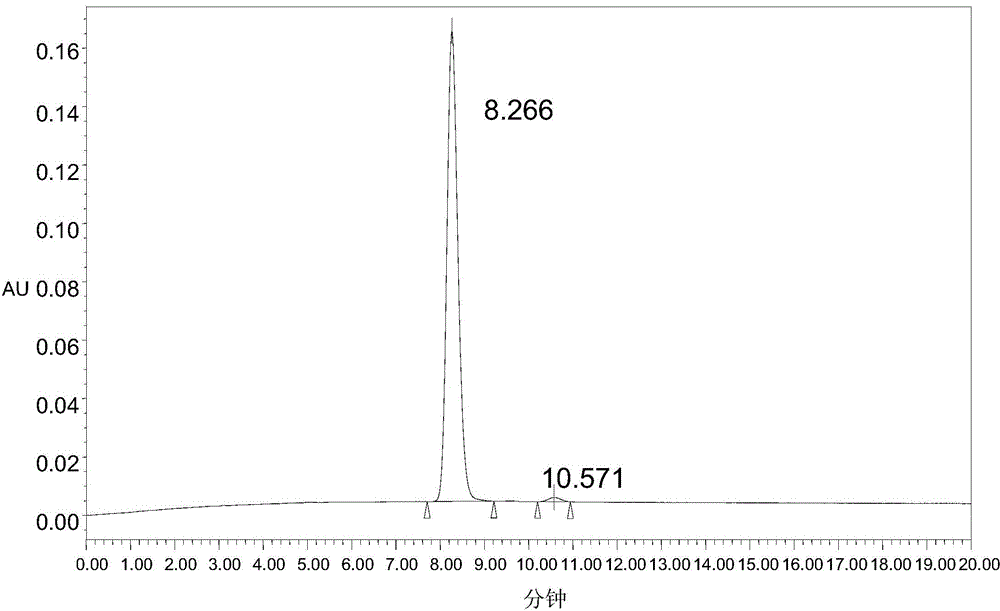

[0038] c) Chromatographic conditions: the semi-preparative chromatographic column is a C8 column (250mm×10mm), and the mobile phase system is

[0039] 70% methanol aqueous solution, the mobile phase flow rate is 5mL / min, and the detection wavelength is 450nm;

[0040] d) Injection volume: 100 μL;

[0041] 100 mL of fucoxanthol prep...

Embodiment 2

[0042] 1) Enzymolysis reaction: take 50 mg of fucoxanthin (purity: 99%), add 150 mg of lipase, 100 mg of sodium taurocholate, dissolve in 0.1M PBS buffer solution with pH=7, and react at 37°C for 1 hour Afterwards, concentrate to dryness, add 50 mL of methanol for ultrasonic extraction, filter, and concentrate the filtrate to dryness to obtain 85 mg of fucoxanthol reactant, and the conversion rate of fucoxanthol is 88%;

[0043] 2) Fucoxanthol refining:

[0044] a) Configuration of raw materials: the crude product of fucoxanthol is configured into a 6 mg / mL solution;

[0045] b) Instrument: semi-preparative high performance liquid chromatography;

[0046]c) Chromatographic conditions: the semi-preparative chromatographic column is a C8 column (250mm×10mm), the mobile phase system is 80% aqueous methanol, the flow rate of the mobile phase is 6mL / min, and the detection wavelength is 450nm;

[0047] d) Injection volume: 300 μL;

[0048] 150 mL of fucoxanthol preparation soluti...

Embodiment 3

[0050] 1) Enzymolysis reaction: Take 50 mg of fucoxanthin (purity: 99%), add 500 mg of lipase, 500 mg of sodium taurocholate, dissolve in 0.1M PBS buffer solution with pH=11, and react at 70°C for 0.5 After h, concentrate to dryness, add 50mL of methanol for ultrasonic extraction, filter, and concentrate the filtrate to dryness to obtain 88mg of fucoxanthol reactant, the conversion rate of fucoxanthol is 55%;

[0051] 2) Fucoxanthol refining:

[0052] a) Configuration of raw materials: the crude product of fucoxanthol is configured into a 6 mg / mL solution;

[0053] b) Instrument: semi-preparative high performance liquid chromatography;

[0054] c) Chromatographic conditions: the semi-preparative chromatographic column is a C18 column (250mm×10mm), the mobile phase system is 90% methanol water-soluble, the flow rate of the mobile phase is 6mL / min, and the detection wavelength is 450nm;

[0055] d) Injection volume: 300 μL;

[0056] 70 mL of fucoxanthol preparation solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com