Method for preparing mineral collagen coating on surface of medical implantation body

A technology for mineralizing collagen and implants, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of affecting the bonding force of the coating, hindering clinical application, large side effects of cathode deposition, etc. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

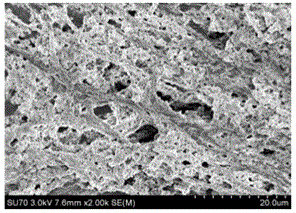

Embodiment 1

[0019] Preparation of electrolyte: Ca(NO 3 ) 2 ·6H 2 O was dissolved in water and prepared as Ca(NO 3 ) 2 aqueous solution, the NH 4 h 2 PO 4 Dissolved in water, prepared as NH with a phosphorus concentration of 80mM 4 h 2 PO 4 aqueous solution, the Ca(NO 3 ) 2 Aqueous solution and NH 4 h 2 PO 4 The aqueous solution is stirred and mixed to obtain a calcium-phosphorus mixed solution. Dissolve Beiling liquid collagen in 0.005mol / L acetic acid, stir to form a collagen acetic acid solution with a collagen concentration of 0.5g / L, add the collagen acetic acid solution to the calcium-phosphorus mixed solution, and make the concentrations of calcium, phosphorus, and collagen respectively 8mmol / L, 8mmol / L, 0.4g / L, then use NH 3 ·H 2 O solution to adjust the pH of the electrolyte to 4.4.

[0020] The titanium plate after surface cleaning is used as the cathode, and the platinum electrode is used as the anode. The distance between the cathode and the anode is 1cm. Take ...

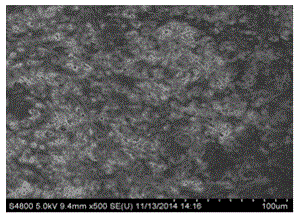

Embodiment 2

[0024] Preparation of electrolyte: CaCl 2 Dissolved in water, formulated as CaCl with a calcium concentration of 80mM 2 aqueous solution, the NaH 2 PO 4 Dissolved in water, prepared as NaH with a phosphorus concentration of 80mM 2 PO 4 aqueous solution, the CaCl 2 Aqueous solution and NaH 2 PO 4 The aqueous solution is stirred and mixed to obtain a calcium-phosphorus mixed solution. Dissolve Beiling liquid collagen in 0.005mol / L acetic acid, stir to form a collagen acetic acid solution with a collagen concentration of 0.5g / L, add the collagen acetic acid solution to the calcium-phosphorus mixed solution, and make the concentrations of calcium, phosphorus, and collagen respectively 8mmol / L, 8mmol / L, 0.4g / L, then use NH 3 ·H 2 O solution to adjust the pH of the electrolyte to 4.4.

[0025] The titanium plate after surface cleaning is used as the cathode, and the platinum electrode is used as the anode. The distance between the cathode and the anode is 1cm. Take 15ml of...

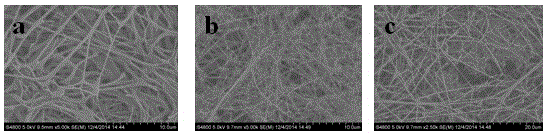

Embodiment 3

[0029] Preparation of electrolyte: Ca(NO 3 ) 2 ·6H 2 O was dissolved in water and prepared as Ca(NO 3 ) 2aqueous solution, the NH 4 h 2 PO 4 Dissolved in water, prepared as NH with a phosphorus concentration of 80mM 4 h 2 PO 4 aqueous solution, the Ca(NO 3 ) 2 Aqueous solution and NH 4 h 2 PO 4 The aqueous solution is stirred and mixed to obtain a calcium-phosphorus mixed solution. Dissolve Beiling liquid collagen in 0.005mol / L acetic acid, stir to form a collagen acetic acid solution with a collagen concentration of 0.5g / L, add the collagen acetic acid solution to the calcium-phosphorus mixed solution, and make the concentrations of calcium, phosphorus, and collagen respectively 10mmol / L, 10mmol / L, 0.4g / L, then use NH 3 ·H 2 O solution to adjust the pH of the electrolyte to 4.4.

[0030] The titanium plate after surface cleaning is used as the cathode, and the platinum electrode is used as the anode. The distance between the cathode and the anode is 1cm. Take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com