Solid sample direct introduction device of microwave plasma torch spectrometer

A microwave plasma and sampling device technology, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problems of high water content in samples, slow speed, large energy and time consumption, etc., and achieve low material state requirements and reasonable device design , The effect of facilitating user needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

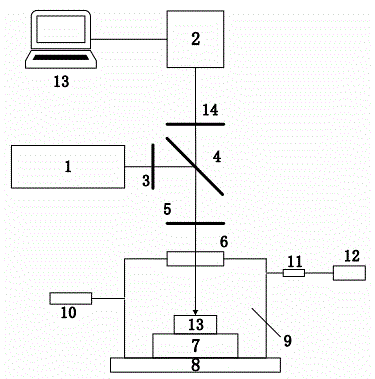

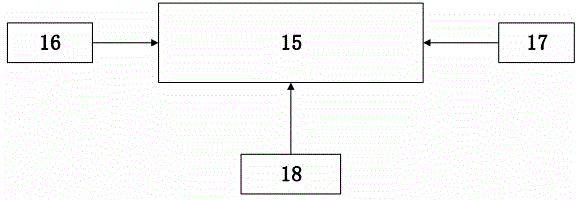

[0025]The present invention consists of a pulsed laser system, an imaging positioning system, a sample processing system, a position adjustment system and a gas path transfer system, specifically consisting of a laser 1, an imaging camera 2, a front optical path group 3, a dichroic mirror 4, and a laser focusing mirror 5 , sample skylight 6, sample rack 7, position adjustment system 8, sample cell 9, helium (or other inert gas) transfer line 10, aerosol transfer line, MPT ion source system 11, MPT ion source system 12, control Computer 13 is formed. The laser beam emitted by the laser 1 is focused on the surface of the sample 13 through optical path adjustment to form an aerosol, which is blown into the aerosol transfer line 11 by helium (or other inert gas) and connected to the MPT; the sample cell 9 is connected to the MPT through the aerosol transfer port 11 The MPT torch 12 of the ion source system is connected.

[0026] attached by figure 1 It can be seen that a sol...

Embodiment 2

[0037] With the device of the present invention, the specific solid sample direct sampling operation steps are as follows:

[0038] 1. Determine the solid sample analysis area

[0039] The sample is moved by the position adjustment system 8 to be imaged in the positioning imaging system, and the movement of the sample 13 is adjusted to determine its position.

[0040] 2. Sampling parameter setting

[0041] The exposure time and focus position of the imaging camera 2 are controlled by the control computer 13, and the laser energy and focus position of the laser are set at the same time.

[0042] 3. Set the gas state of the carrier gas helium (or other inert gas)

[0043] Set the gas flow rate and pressure of helium (or other inert gas), and then bring the solid sample aerosol formed after laser ablation into the MPT torch of the MPT ion source system.

[0044] 4. Sample ablation, status monitoring

[0045] After the laser is focused on the surface of the sample to form an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com