Xanthogen-modified chloroprene rubber and production method therefor

A technology of chloroprene rubber and chloroprene, which is applied in the field of xanthan-modified chloroprene rubber and its manufacture, can solve the problems of difficult productivity and insufficient dynamic characteristics, and achieve the improvement of dynamic characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

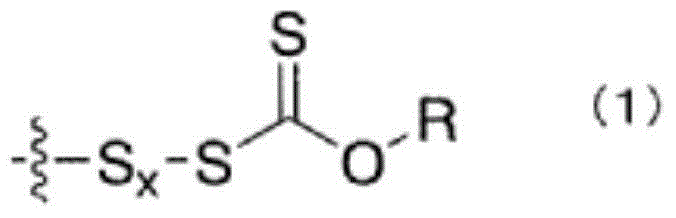

[0065] As a monomer mixture, 8 g of diisopropylxanthogen polysulfide represented by the following general formula (4) is added relative to 1000 g of chloroprene (relative to 100 parts by weight of the monomer mixture, diisopropylxanthogen polysulfide The sulfide is 0.8 parts by weight), mixed and stirred with an emulsified aqueous solution of 50 g of potassium salt of abietic acid, 10 g of sodium salt of a condensate of naphthalenesulfonic acid and formaldehyde, 3 g of sodium hydroxide, and 1000 g of water to emulsify it.

[0066]

[0067] (In the formula, x is an integer of 3 to 5.)

[0068] A polymerization catalyst comprising 1 g of potassium persulfate, 0.1 g of sodium anthraquinone-β-sulfonate, and 300 g of water was added thereto at a constant rate by a pump, and emulsion polymerization was performed at 30°C. Emulsion polymerization is carried out by adding a polymerization catalyst until the polymerization conversion rate is 70%, and then adding a polymerization term...

Embodiment 2

[0077] Change the diisopropyl xanthogen polysulfide as chain transfer agent to 5g (relative to 100 weight parts of monomer mixture, diisopropyl xanthogen polysulfide is 0.5 weight part), in addition, with the embodiment 1 was carried out in the same manner to obtain a xanthan-modified chloroprene rubber (0.10 parts by weight of diisopropylxanthogen polysulfide per 100 parts by weight of chloroprene rubber).

[0078] The obtained purified xanthogen-modified chloroprene rubber was subjected to pyrolysis GC / MS in the same manner as in Example 1, and the same results were obtained.

[0079] Mooney viscosity measurement and evaluation of dynamic properties were performed on the obtained xanthan-modified chloroprene rubber. Record the results in Table 1. The loss coefficient (tan δ) was lower than that of the comparative example, and the dynamic characteristics were excellent.

Embodiment 3

[0081] Change the diisopropylxanthogen polysulfide as a chain transfer agent to 4 g (with respect to 100 parts by weight of the monomer mixture, diisopropylxanthogen polysulfide is 0.4 parts by weight) and diethylxanthogen disulfide 1 g of the product (with respect to 100 parts by weight of the monomer mixture, diisopropyl xanthogen polysulfide is 0.1 parts by weight), except that, proceed in the same manner as in Example 1 to obtain xanthan modified chloroprene rubber ( Diisopropylxanthogen polysulfide is 0.08 parts by weight relative to 100 parts by weight of chloroprene rubber).

[0082] The obtained purified xanthogen-modified chloroprene rubber was subjected to pyrolysis GC / MS in the same manner as in Example 1, and the same results were obtained.

[0083] Mooney viscosity measurement and evaluation of dynamic properties were performed on the obtained xanthan-modified chloroprene rubber. Record the results in Table 1. The loss coefficient (tan δ) was lower than that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com