Electrochromic material and electrochromic device

A technology of electrochromic materials and electrochromic devices, which is applied in the direction of color-changing fluorescent materials, instruments, chemical instruments and methods, etc., can solve the problems of shortened life and long fading time of electrochromic devices, and achieve fast discoloration and fading speed , long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

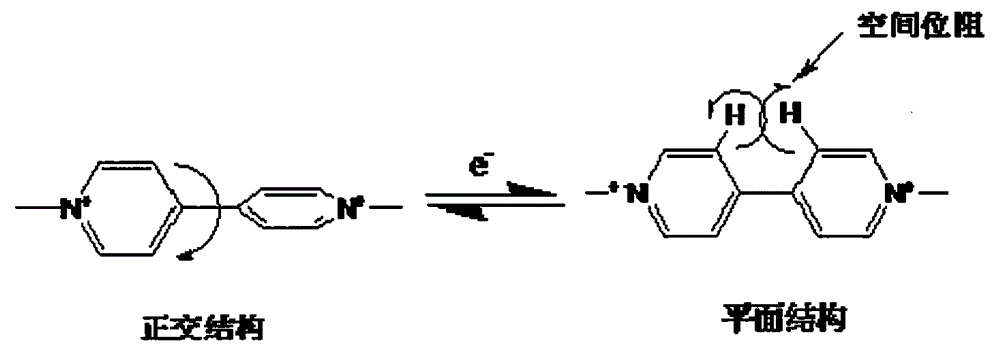

Problems solved by technology

Method used

Image

Examples

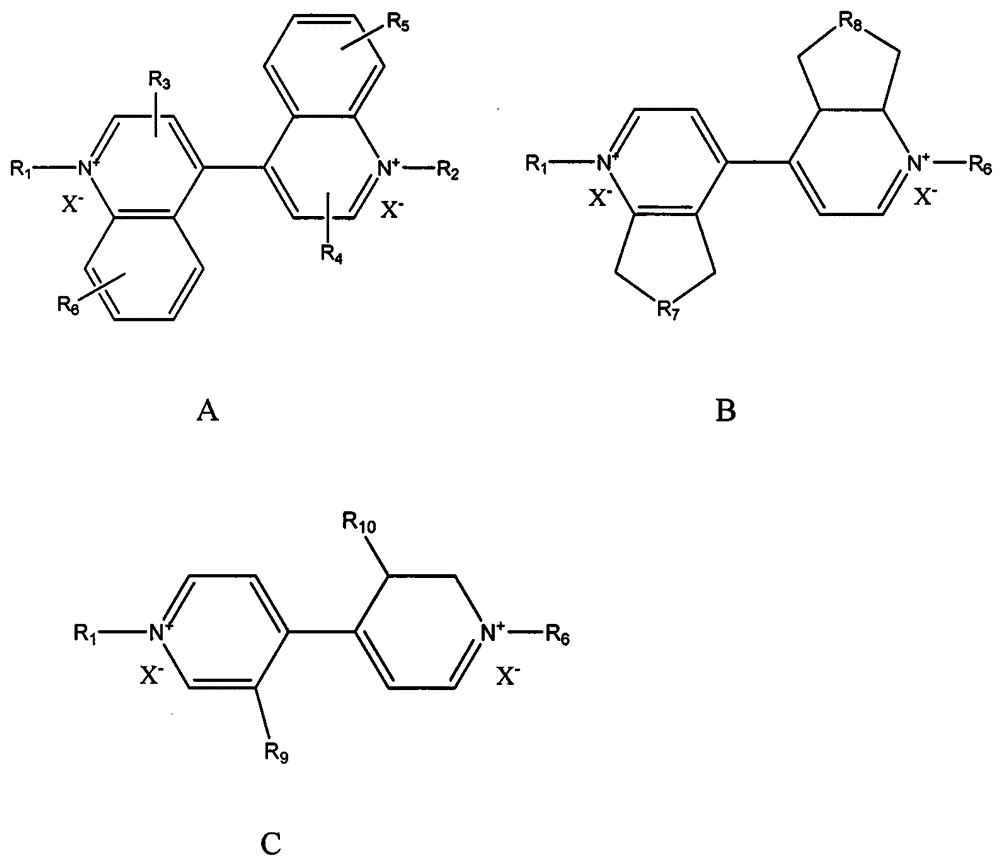

Embodiment 1

[0038] Add 0.1mol of 3-methylpyridine and 0.025mol of sodium metal into the reaction flask, heat to 110°C and reflux for 24 hours. After the reaction is completed, cool to room temperature and pour the mixture into ice cubes to remove excess sodium metal. The reaction is complete. An oil-water mixture is obtained, and the oil-water separation is carried out. Add anhydrous sodium sulfate to the obtained oily matter, let it stand overnight, and then rotary evaporate under reduced pressure to remove excess 3-picoline. The product obtained after rotary evaporation is recrystallized in ethanol solution to obtain a white or light yellow product, namely 3,3-dimethyl-4,4-bipyridine. Take 0.02 mol of 3,3-dimethyl-4,4-bipyridine and dissolve it in 20 mL of acetonitrile solution, then add 0.05 mol of bromoethane, and reflux for 8 hours. After the reaction, the obtained mixed solution was filtered, and the filter cake was dissolved in deionized water, and sodium fluoroborate was added, ...

Embodiment 2

[0041]Add 0.1mol of 3-phenylpyridine and 0.025mol of sodium metal into the reaction flask, heat to 110°C and reflux for 24 hours, after the reaction is completed, cool to room temperature, and pour the mixture into ice cubes to make the excess sodium metal The reaction is complete. An oil-water mixture is obtained, and the oil-water separation is carried out. Add anhydrous sodium sulfate to the obtained oily matter, let it stand overnight, and then rotary evaporate under reduced pressure to remove excess 3-phenylpyridine. The product obtained after rotary evaporation is recrystallized in ethanol solution to obtain a white or light yellow product, namely 3,3-diphenyl-4,4-bipyridine. Take 0.02 mol of 3,3-diphenyl-4,4-bipyridine and dissolve it in 20 mL of acetonitrile solution, then add 0.05 mol of heptane bromide, and react under reflux for 8 hours. After the reaction, the obtained mixed solution was filtered, and the filter cake was dissolved in deionized water, and sodium p...

Embodiment 3

[0044] Add 0.1mol of quinoline and 0.025mol of sodium metal into the reaction flask, heat to 120°C and reflux for 24 hours. After the reaction is completed, cool to room temperature and pour the mixture into ice cubes to complete the reaction of excess sodium metal. An oil-water mixture is obtained, and the oil-water separation is carried out. Add anhydrous sodium sulfate to the obtained oily matter, let stand overnight, and then remove excess quinoline by rotary evaporation under reduced pressure. The product obtained after rotary evaporation is recrystallized in ethanol solution to obtain a white or light yellow product, namely 4-(quinolin-4-y1)quinoline. Take 0.02 mol of 4-(quinolin-4-yl)quinoline and dissolve it in 20 mL of acetonitrile solution, then add 0.05 mol of n-dodecane bromide, and react under reflux for 8 hours. After the reaction, the obtained mixed solution was filtered, and the filter cake was dissolved in deionized water, and sodium dodecylbenzenesulfonate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com