A kind of chromium-free passivation solution for galvanized layer and using method thereof

A chrome-free passivation, galvanized sheet technology, applied in the direction of metal material coating process, can solve the problem of lack of chromate self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

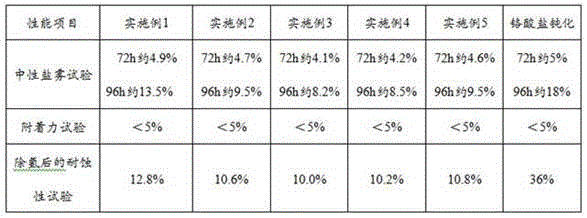

Examples

Embodiment approach

[0045] As a preferred embodiment of the present invention, the chromium-free passivation solution also includes trimethylolpropane trimethacrylate TMPTMA used as a cross-linking agent, the amount of the cross-linking agent being the water-based alkyd 12~25% of the total mass of the resin.

[0046] As a preferred embodiment of the present invention, the water-based alkyd resin is a hyperbranched alkyd resin, which is based on trimethylolpropane, dimethylol propionic acid, linolenic acid, phthalic anhydride, maleic acid Diene acid anhydride is synthesized as a raw material, and the degree of branching of the hyperbranched alkyd resin is 0.5~0.6, and the number average molecular weight M n =4.68×10 3 g / mol, mass average molecular mass M w =5.4×10 3 g / mol, polydispersity index M w / M n =1.15.

[0047] As another preferred embodiment of the present invention, the water-based alkyd resin is a hyperbranched alkyd resin, which is based on dipentaerythritol, dimethylol propionic ...

Embodiment 1

[0059] A chromium-free passivation solution for zinc plating and a method for using the same, wherein the chromium-free passivation solution includes the following raw materials in weight percent:

[0060] Waterborne Alkyd 25%

[0061] Sodium molybdate 1%

[0063] The balance is water

[0064] Phosphoric acid to adjust pH to 1~3

[0065] The water-based alkyd resin is prepared through the following steps: in a 500ml four-necked flask equipped with a stirrer, a thermometer, and an oil-water separator, add 1.073mol of linoleic acid, 1.016mol of glycerol, and xylene (accounting for the total amount of the formula) at one time. 5~10% of mass), 1 mol of phthalic anhydride, and catalyst LiOH (0.02% of linoleic acid), CO 2 , stir, heat up to 160°C within 40~50min, then gradually raise the temperature to 220~230°C within 1~3h, keep the esterification until the acid value is below 10 mgKOH / g, and the viscosity (Gargerian tube) reaches 10s as the reac...

Embodiment 2

[0069] A kind of chromium-free passivation solution for galvanized layer, described chromium-free passivation solution comprises the raw material of following percentage by weight:

[0070] TMPTMA modified water-based alkyd resin 20%

[0071] Potassium molybdate 3%

[0073] The balance is water

[0074] Phosphoric acid to adjust pH to 1~3

[0075] The TMPTMA modified water-based alkyd resin is prepared through the following steps: according to the same method as in Example 1, the water-based alkyd resin with an acid value of 55 ~ 65mgKOH / g is prepared, and 20% of the alkyd resin quality is added to it by titration The TMPTMA, control the titration time for 2h, and then react at 170°C for 2h. Infrared spectrum detection shows that the TMPTMA modified water-based alkyd resin has been synthesized.

[0076] The preparation method and usage method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com