Phosphate lithium fast ion conductor material and preparation method thereof

A technology of conductor materials and ion conductors, applied in the field of component design and preparation of lithium fast ion conductor materials, can solve the problems of low material density, gap in ion conductivity, high room temperature conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] Preparation of Lithium Phosphate Fast Ion Conductor Material

[0087] The invention also provides a method for preparing the material. In the prior art, the method for preparing lithium phosphate fast ion conductor materials needs to immediately anneal the glass formed after quenching at a medium-high temperature, such as 500°C. This process can easily cause cracks in the glass due to stress, and eventually affect material properties.

[0088]In the present invention, after high-temperature quenching to form glass, instead of immediately performing medium-high temperature annealing, it is immediately and thoroughly cooled, and then the glass powder is prepared, and finally the powder is pressed and annealed. This processing method can be very good The possibility of cracks in the current technology can be avoided, and dense and stable materials can be prepared well by subsequent cold isostatic pressing and annealing.

[0089] Specifically, the present invention provid...

Embodiment 1

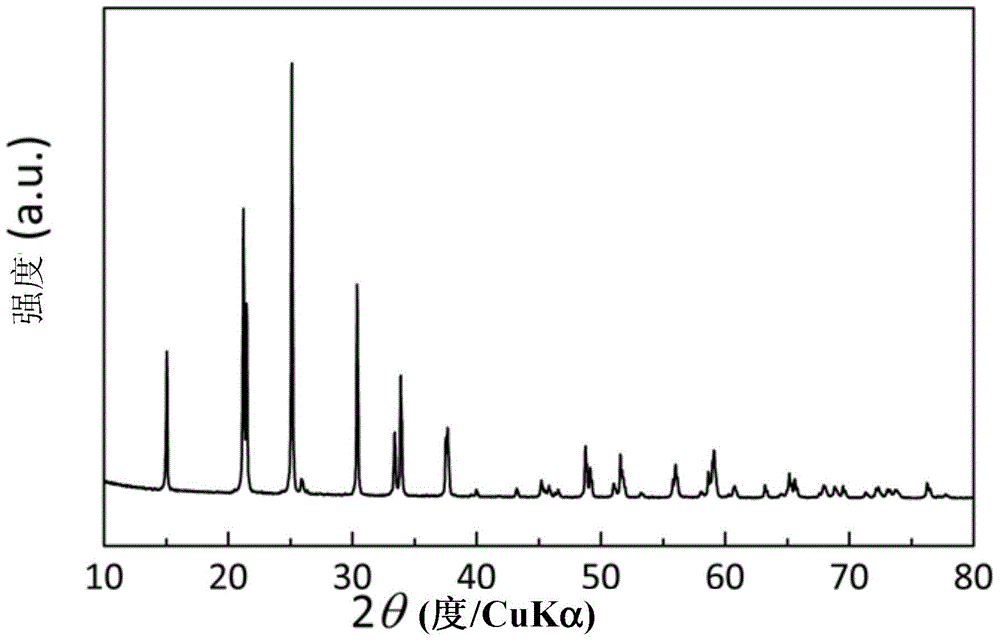

[0121] Will Li 2 CO 3 : Al(OH) 3 : GeO 2 : SiO 2 : NH 4 h 2 PO 4 According to Li 1.61 al 0.5 Ge 1.5 Si 0.01 P 2.99 o 12.05 Stoichiometric ingredients, evenly mixed and dried. The powder was heated to 700°C for 2 hours, cooled and crushed under wet grinding conditions and dried. Then heat the powder to 1400°C and keep it warm for 2 hours, and then pour it into liquid nitrogen to quench. After the product is cooled, it is pulverized and dried under wet grinding conditions, and the glass powder is pressed under 300 MPa. The block was first kept at 520°C for 6 hours, then at 900°C for 6 hours, and then cooled in the furnace to obtain a glass ceramic lithium fast ion block material. After the glass-ceramic block is machined, gold is used as the blocking electrode, and the AC impedance test is carried out at room temperature, and the test frequency is 1 MHz to 0.1 Hz. The ionic conductivity of the sample is obtained by calculation, and the room temperature AC impedan...

Embodiment 2

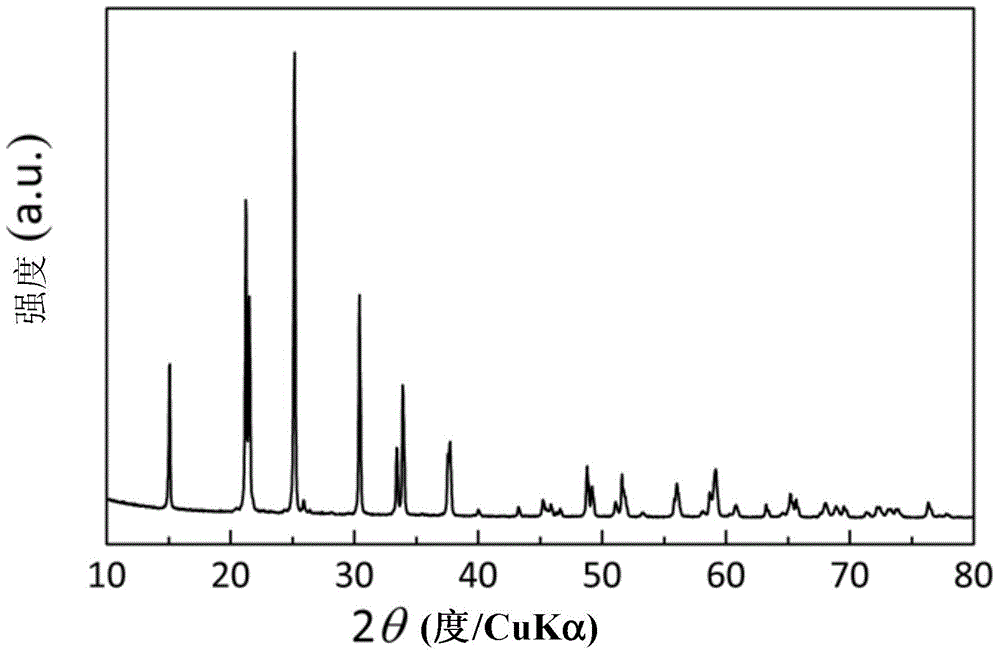

[0123] Will Li 2 CO 3 : Al(OH) 3 : GeO 2 : SiO 2 : NH 4 h 2 PO 4 According to Li1.62 Al 0.5 Ge 1.5 Si 0.02 P 2.98 o 12.05 Stoichiometric ingredients, evenly mixed and dried. The powder was heated to 750°C for 2 hours, cooled and crushed under wet grinding conditions and dried. Then heat the powder to 1450°C and keep it warm for 2 hours, and then pour it into liquid nitrogen to quench. After the product is cooled, it is pulverized and dried under wet grinding conditions, and the glass powder is pressed under 300 MPa. The block was first kept at 550°C for 4h, then at 900°C for 6h, and then cooled in the furnace to obtain a glass-ceramic lithium fast ion block material. After the glass-ceramic block is machined, gold is used as the blocking electrode, and the AC impedance test is carried out at room temperature, and the test frequency is 1 MHz to 0.1 Hz. The ionic conductivity of the sample was obtained by calculation, and its room temperature ionic conductivity wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com