Modified peanut shell adsorbent for treating sunset yellow dye wastewater and its preparing method and application thereof

A technology for dye wastewater and peanut shells, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of cumbersome operation, high cost, and large energy consumption, and achieve enhanced adsorption effect and reduced Treatment cost, effect of physical strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 peanut shell epoxy cellulose ether intermediate

[0027] (1) Peanut shells are washed and pulverized, and passed through a 40-mesh sieve;

[0028] (2) Take the sieved peanut shell powder, add epichlorohydrin whose volume is 12.5 times the weight of the peanut shell powder, mix well, then add NaOH solution to react, filter after the reaction, wash with water until neutral, and dry. Obtain an epoxy-based cellulose ether intermediate; the weight ratio of the content of NaOH in the NaOH solution to the amount of peanut shell powder added is 1:1.8; the temperature of the reaction is 40°C, and the reaction time is 4h; the drying Drying means drying at 50-70°C.

Embodiment 2

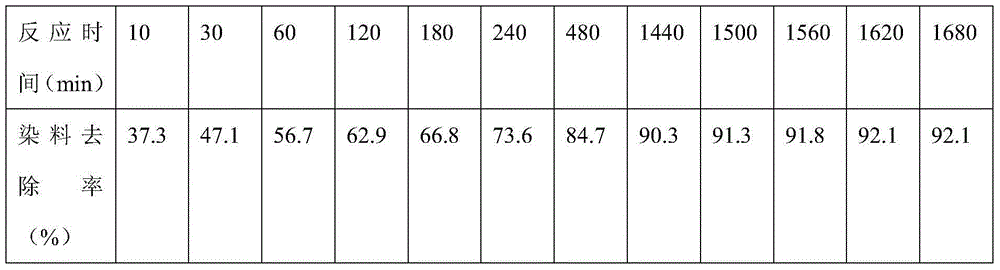

[0029] Embodiment 2 Influence of reaction time on the adsorption effect of adsorbent in the process of generating adsorbent by peanut shell epoxy cellulose ether intermediate

[0030] Get 2.0g of the peanut shell epoxy cellulose ether intermediate obtained according to Example 1, after mixing with ethylenediamine in a ratio of 1:1 (w / v), add Na 2 CO 3 solution, Na 2 CO 3 Na in solution 2 CO 3 The weight ratio of the content of epoxy cellulose ether intermediate to the added amount of epoxy cellulose ether is 1:0.53, react at 65°C for 1-5h, filter, wash with water until neutral, and dry at 50-70°C to obtain modified Peanut shell sunset yellow dye adsorbent.

[0031] Accurately weigh 0.1 g of the above-mentioned modified peanut shell adsorbents prepared under different reaction times, add 30 mL of sunset yellow solution with a concentration of 200 mg / L, adjust the pH to about 2.0, and place them in a constant temperature water bath shaker. Shake for 15 hours at a speed of ...

Embodiment 3

[0035] Example 3 Influence of reaction temperature on the adsorption effect of adsorbent in the process of generating adsorbent from peanut shell epoxy cellulose ether intermediate

[0036] Get 2.0g of the peanut shell epoxy cellulose ether intermediate obtained according to Example 1, mix it with ethylenediamine in a ratio of 1:1 (w / v), add 0.1mol / L Na 2 CO 3 100 mL of the solution was reacted at 45-75°C for 2 hours, filtered, washed with water until neutral, and dried at 50-70°C to obtain the modified peanut shell sunset yellow dye adsorbent.

[0037] Accurately weigh 0.1 g of the above-mentioned modified peanut shell adsorbent prepared at different reaction temperatures, add 30 mL of sunset yellow solution with a concentration of 200 mg / L, adjust the pH to about 2.0, place in a constant temperature water bath shaker, and Shake for 15 hours at a speed of 150 rpm, measure the concentration of sunset yellow in the residual liquid, and calculate the removal rate. The results a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com