Solid phase reaction preparation method of cuprous sulfide nanopowder

A technology of nano-powder and cuprous sulfide, applied in the field of nano-materials, can solve the problems of complex preparation process, easy agglomeration of product particles, difficult to clean up, etc., and achieve simple preparation process, good photocatalytic activity and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

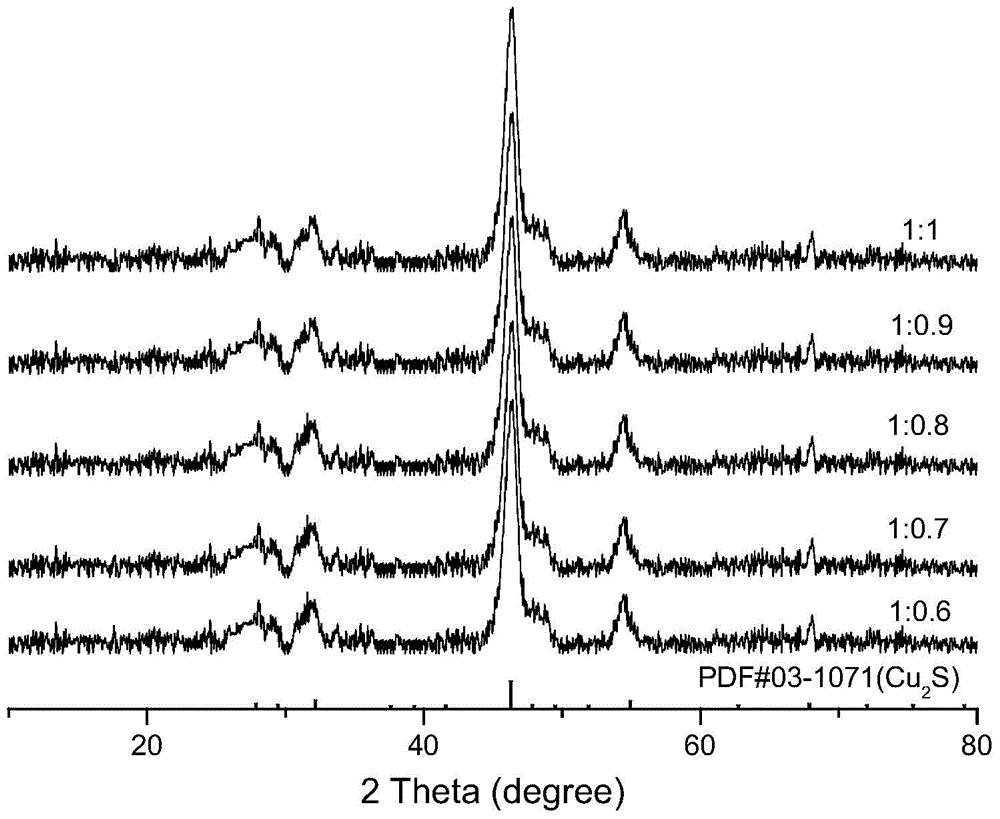

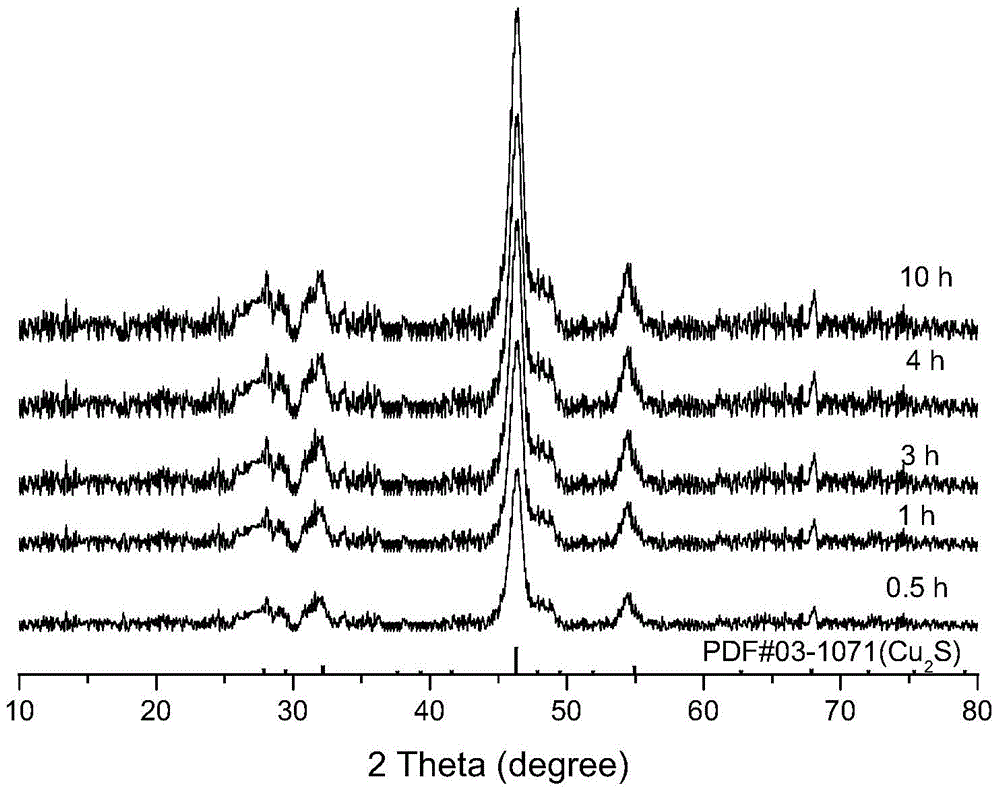

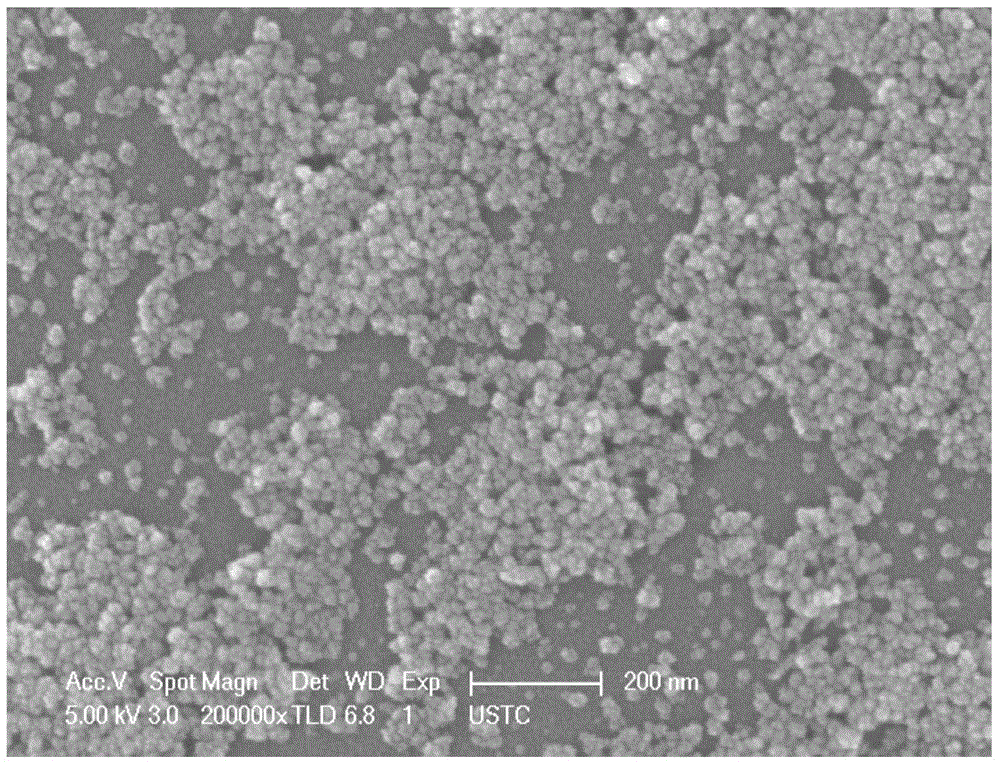

[0021] Weigh 0.02 moles of analytically pure CuCl and 0.012 moles of analytically pure Na according to the molar ratio of 1:0.6 2 S·9H 2 O was added into a 50mL zirconia ball mill jar equipped with 50 zirconia balls with a diameter of 6mm and 8 zirconia balls with a diameter of 10mm and continuously ground for 2.0 hours. Vacuum drying at 80°C and 0.1MPa vacuum for 2 hours to obtain an average grain size of 29.7nm Cu 2 S nano powder.

Embodiment 2

[0023] Weigh 0.02 moles of analytically pure CuCl and 0.014 moles of analytically pure Na according to a molar ratio of 1:0.7 2 S·9H 2 O was added into a 50mL zirconia ball mill jar equipped with 50 zirconia balls with a diameter of 6mm and 8 zirconia balls with a diameter of 10mm and continuously ground for 2.0 hours. Vacuum drying at 80°C and 0.1MPa vacuum for 2 hours to obtain an average grain size of 29.6nm Cu 2 S nano powder.

Embodiment 3

[0025] Weigh 0.02 moles of analytically pure CuCl and 0.016 moles of analytically pure Na according to a molar ratio of 1:0.8 2 S·9H 2 O was added into a 50mL zirconia ball mill jar equipped with 50 zirconia balls with a diameter of 6mm and 8 zirconia balls with a diameter of 10mm and continuously ground for 2.0 hours. Vacuum drying at 80°C and 0.1MPa vacuum for 2 hours to obtain an average grain size of 29.4nm Cu 2 S nano powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The size of granule | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com