Solidifying and melting composite material increase forming method suitable for complex parts

A technology for additive forming and complex parts, applied in the field of additive forming of parts, which can solve the problems of low material utilization rate, high operating cost, poor forming quality of parts, etc., and achieves no arc radiation pollution, good working conditions, and stable formability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

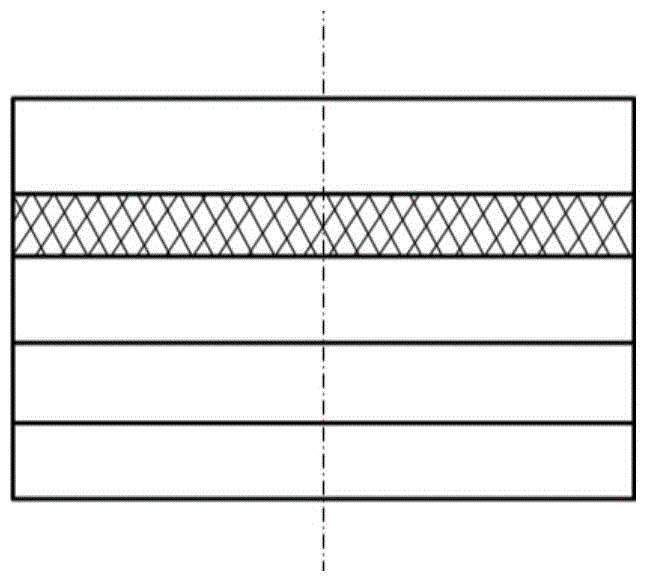

[0024] A solid-solution composite additive forming method suitable for solid cylindrical aluminum alloy parts as shown in Figure 1, which comprises the following steps:

[0025] (1) Referring to Fig. 1(a), establish the CAD geometric model of the part according to the three-dimensional shape and size of the target solid cylindrical aluminum alloy part, extract the STL model of the part, and select a layered thickness of 1.5mm according to the actual forming shape and size of the part; Referring to Fig. 1 (b) according to the STL model and layer thickness, the STL model is divided into 5 layers with a thickness of 1.5mm by the layered slicing software with a unit of 1.5mm. In this embodiment, layers 1-3 are selected Aluminum plate, insulating plate is used for the 4th layer, and copper plate is used for the 5th layer;

[0026] (2) Extract the inner and outer contour points of the STL model of each layer, and then perform filling processing based on these inner and outer contour...

Embodiment 2

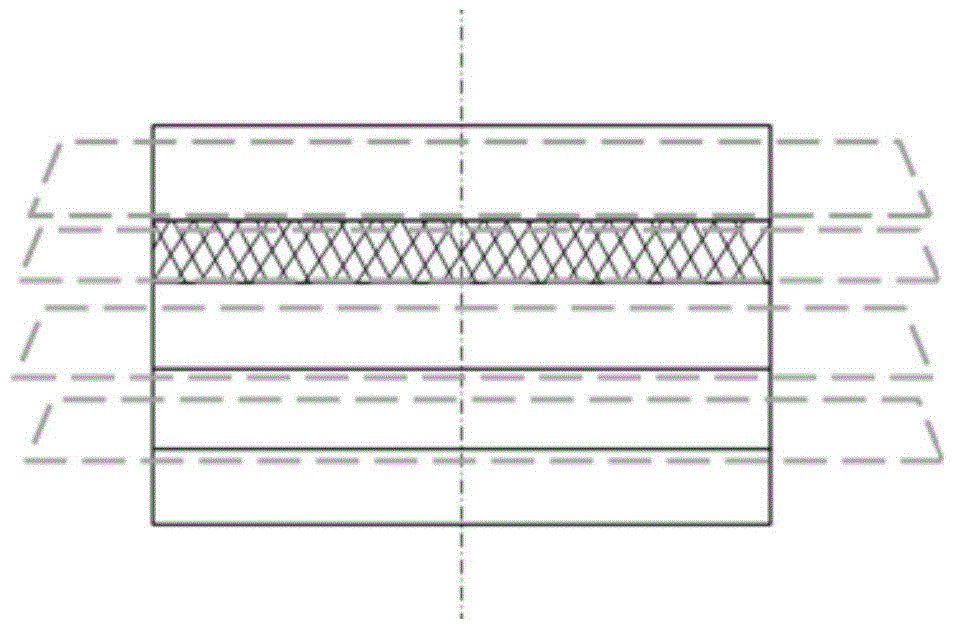

[0031] A solid-solution composite additive forming method suitable for complex metal parts with holes in the middle as shown in Figure 2, which includes the following steps:

[0032](1) Referring to Figure 2(a), the CAD geometric model of the part is established according to the three-dimensional shape and size of the target part, the STL model of the part is extracted, and the layer thickness is selected according to the actual shape and size of the part. In the actual operation process, the The layer thickness can be selected according to the actual needs. According to the shape and complexity of the part, the layer thickness of each layer can be the same or different, which is determined by the processing technology requirements of the part. The operator can make a reasonable selection and division according to the needs. In this embodiment, the layered thickness of each layer is selected to be 1mm; see Figure 2 (b) according to the STL model and layered thickness, the STL m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com