A kind of preparation method and application of phosphorus-containing polyether ester

A polyether ester and reactor technology, which is applied in the field of preparation of phosphorus-containing polyether ester, can solve the problems of not being able to meet the requirements at the same time, not being environmentally friendly, etc., and achieve the effects of excellent anti-dripping, low cost, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

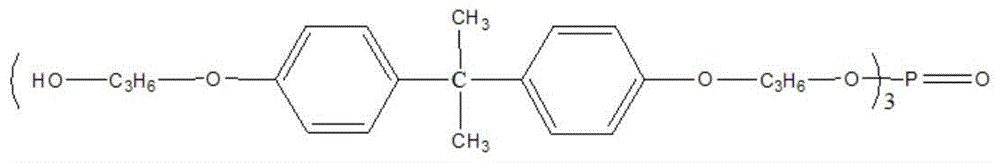

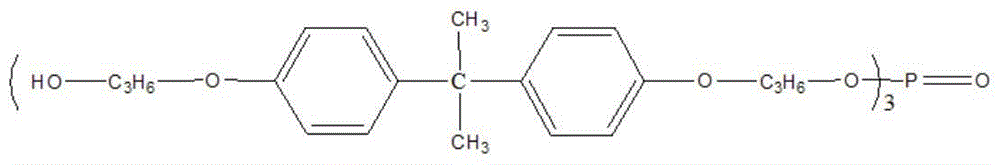

Image

Examples

Embodiment 1

[0048] Add 50kg of toluene to the reaction kettle, raise the temperature to 60°C while stirring, then add 103.2kg of D-33 into the reaction kettle while maintaining stirring and heating, stop heating until D-33 is completely dissolved, and cool down with cooling water To 25°C, control the temperature at 15-25°C and add 15.3 kg of phosphorus oxychloride dropwise to the reactor at a rate of about 5 kg / h, and the drop will be completed in about 3 hours. During this process, hydrogen chloride gas will escape from the reactor. , so that the escaped gas is passed into the lye tank, and the acid gas is absorbed with a sodium hydroxide solution with a mass concentration of 50% in the tank. The gas not absorbed by the lye tank is inert solvent vapor, which will be recovered by the condenser connected after the lye tank. After the dropwise addition of phosphorus oxychloride is completed, the temperature of the material in the reactor is raised to 110°C within 3 hours, so that the materi...

Embodiment 2

[0058] Add 50kg of toluene to the reaction kettle, raise the temperature to 70°C while stirring, then add 86kg of D-33 and 3.7kg of butanol into the reaction kettle successively while maintaining stirring and heating until D-33 is completely melted and stop Heating, passing cooling water to cool down to 15°C, and slowly adding 15.3kg of phosphorus oxychloride to the reactor at 15-25°C under control of the temperature. The lye tank uses a 10% sodium hydroxide solution to absorb acid gas in the tank. The gas not absorbed by the lye tank is inert solvent vapor, which will be recovered by the condenser connected after the lye tank. After the phosphorus oxychloride has been added dropwise, the temperature of the material in the reactor is raised to 130°C within 4 hours, so that the material in the kettle reaches a slight boiling state, and is kept in this state for 4 hours, and then the condenser, lye Vacuumize the tank and reactor, extract residual hydrogen chloride and all tolue...

Embodiment 3

[0067] Add 50kg of toluene to the reaction kettle, raise the temperature to 80°C while stirring, then add 86kg of D-33 and 2.3kg of absolute ethanol into the reaction kettle successively while maintaining stirring and heating until D-33 is completely dissolved Then stop heating, pass cooling water to cool down to 20°C, control the temperature at 15-25°C and slowly add 15.3kg of phosphorus oxychloride into the reactor dropwise, and drop it in about 3 hours. During this process, hydrogen chloride gas will be generated in the reactor Escape, make the escaped gas pass into the lye tank, and absorb the acid gas with a sodium hydroxide solution with a mass concentration of 30%. The gas not absorbed by the lye tank is inert solvent vapor, which will be recovered by the condenser connected after the lye tank. After the phosphorus oxychloride has been added dropwise, the temperature of the material in the reactor is raised to 120°C within 3.5 hours, so that the material in the kettle r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com