Method for enhancing mussel astaxanthin fermentation production yield

A technology of red shrimp and green pigment, applied in the field of microorganisms, can solve problems such as high prices and failure to meet market demand, and achieve the effects of reducing production costs, reducing fermentation operating costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

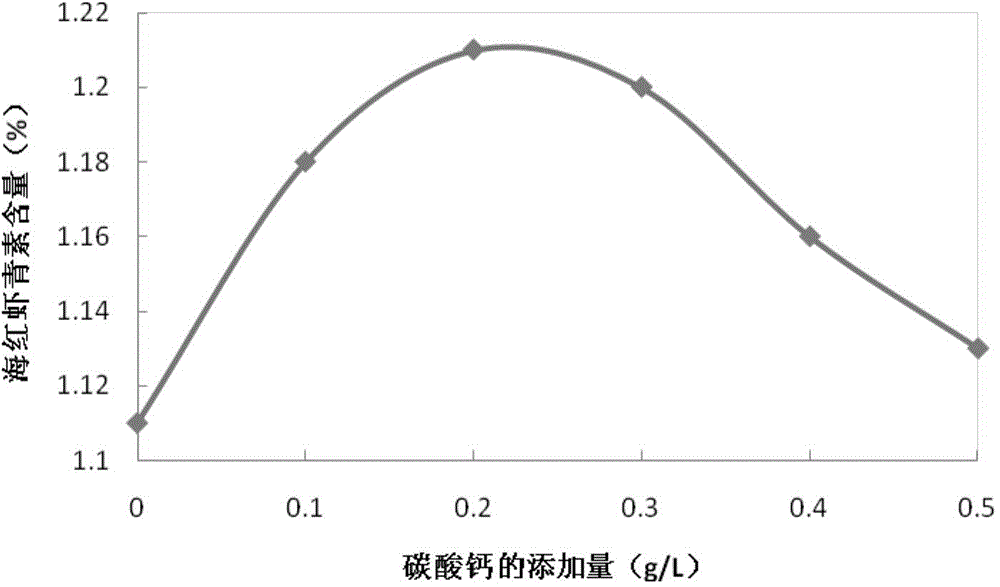

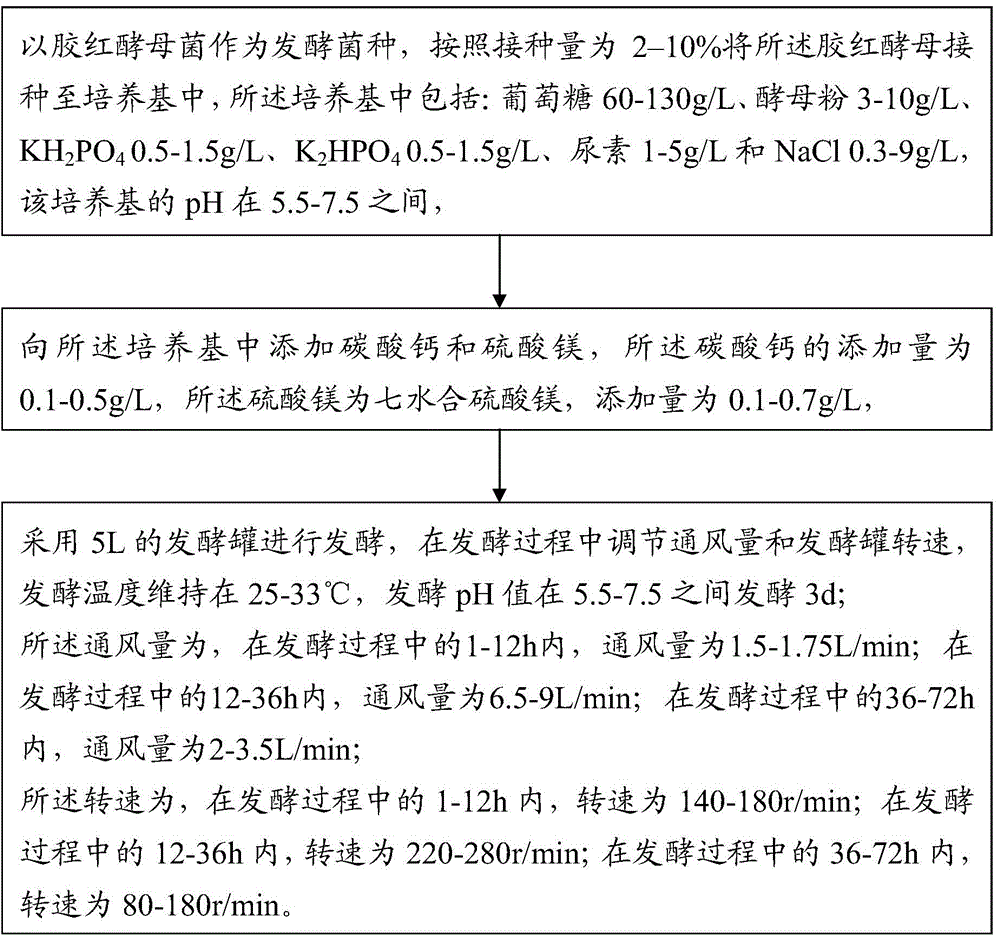

[0027] This example provides a method for improving the yield of sea red astaxanthin produced by fermentation, which is realized by the following steps: using Rhodotorula gelatinum as the fermentation strain, according to the inoculum size of 2%, inoculating the rhodotorula gelatinous yeast into the culture medium , the medium includes: glucose 60g / L, yeast powder 3g / L, KH 2 PO 4 0.5g / L, K 2 HPO 4 0.5g / L, urea 1g / L and NaCl0.3g / L, the pH of this culture medium is 6.5, in described culture medium, add calcium carbonate and magnesium sulfate, adopt the fermentor of 5L to carry out fermentation, adjust in fermentation process The ventilation rate and the rotation speed of the fermenter, the fermentation temperature was maintained at 25°C, and the fermentation pH value was 5.5 for 3 days of fermentation.

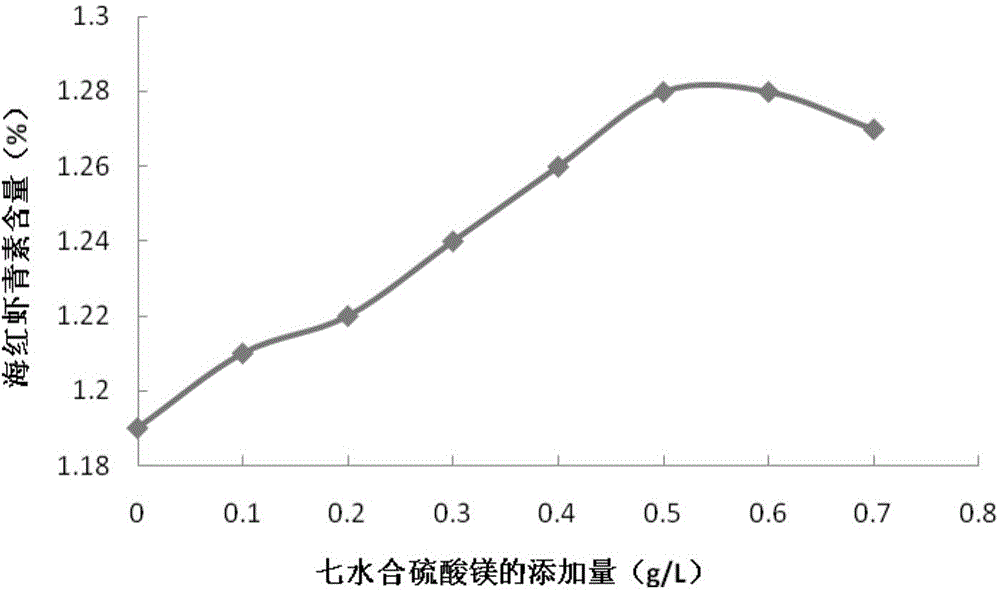

[0028] The calcium carbonate is added in an amount of 0.1 g / L, and the magnesium sulfate is magnesium sulfate heptahydrate, and the added amount is 0.1-0.7 g / L.

[0029] T...

Embodiment 2

[0032] This example provides a method for improving the yield of sea red astaxanthin produced by fermentation, which is realized by the following steps: using Rhodotorula gelatin as the fermentation strain, and inoculating the rhodotorula gelatin into the culture medium according to the inoculum size of 10% In, the medium includes: glucose 130g / L, yeast powder 10g / L, KH 2 PO 4 1.5g / L, K 2 HPO 4 1.5g / L, urea 5g / L and NaCl9g / L, the pH of this culture medium is 7.5, adds calcium carbonate and magnesium sulfate in described culture medium, adopts the fermentor of 5L to carry out fermentation, regulates ventilation in fermentation process and the rotation speed of the fermenter, the fermentation temperature was maintained at 25°C, and the pH value was 7.5 for 3 days of fermentation.

[0033] The addition amount of described calcium carbonate is 0.5g / L, and described magnesium sulfate is magnesium sulfate heptahydrate, and addition amount is 0.7g / L.

[0034] The ventilation ra...

Embodiment 3

[0037] This example provides a method for improving the yield of sea red astaxanthin produced by fermentation, which is realized by the following steps: using Rhodotorula gelatinum as the fermentation strain, according to the inoculum size of 6%, inoculating the rhodotorula gelatinous yeast into the culture medium In, the medium includes: glucose 95g / L, yeast powder 7g / L, KH 2PO 4 1g / L, K 2 HPO 4 1g / L, urea 3g / L and NaCl4.65g / L, the pH of this culture medium is 6.5, add calcium carbonate and magnesium sulfate in described culture medium, adopt the fermentation tank of 5L to carry out fermentation, regulate ventilation during fermentation The fermentation temperature was maintained at 31°C, and the fermentation pH value was 6.5 for 3 days.

[0038] The addition of described calcium carbonate is 0.3g / L, and described magnesium sulfate is magnesium sulfate heptahydrate, and addition is 0.4g / L.

[0039] The ventilation rate is 1.65L / min in 1-12h during the fermentation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com