Application of Cr3+ doped PZT film in preparation of ferroelectric film solar cell

A technology of solar cells and ferroelectric thin films, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of reduced transparency and conductivity, low photoelectric conversion efficiency, and reduced depolarization field, and achieves Improve the efficiency of photovoltaic power generation and improve the effect of residual polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

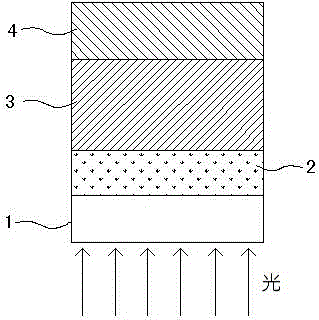

[0035] Deposit an ITO conductive layer on the glass to form a transparent ITO conductive glass (ITO / glass), with a light transmittance greater than 85% and a surface resistivity of about 90Ω / □; deposit a thickness of 400nm on the ITO / glass by sol-gel method The PZT film with a Cr3+ doping concentration of 2% is annealed in air at 520°C to form a polycrystalline Cr3+ doped PZT film (PCZT2); then, use magnetron sputtering ITO conductive layer on PCZT2 / ITO / glass, Form ITO / PCZT2 / ITO / glass structure, that is, ferroelectric thin film solar cells with high remanent polarization; figure 1 A schematic diagram of its structure.

Embodiment 2

[0037] Deposit an ITO conductive layer on the glass to form an ITO conductive glass. Its light transmittance is greater than 85%, and its surface resistivity is about 90Ω / □, forming a conductive and transparent conductive ITO / glass; use sol-gel method to deposit on ITO / glass A 400nm-thick PZT film with a Cr3+ doping concentration of 5% was annealed in air at 520°C to form a polycrystalline Cr3+-doped PZT film (PCZT5); then, magnetron sputtering ITO was used to conduct electricity on PCZT5 / ITO / glass. Layer 2 forms an ITO / PCZT5 / ITO / glass structure, that is, a ferroelectric thin film solar cell with high residual polarization.

Embodiment 3

[0039] Deposit an ITO conductive layer 1 on the glass to form an ITO conductive glass with a light transmittance greater than 85% and a surface resistivity of about 90Ω / □, forming a conductive and transparent conductive ITO / glass; using the sol-gel method on the ITO / glass Deposit a 400nm-thick PZT film with a Cr3+ doping concentration of 10%, and anneal at 520°C in air to form a polycrystalline Cr3+-doped PZT film (PCZT10); then, magnetron sputtering ITO on PCZT10 / ITO / glass The conductive layer 2 forms an ITO / PCZT10 / ITO / glass structure, that is, a ferroelectric thin film solar cell with high residual polarization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com