Production method of living vaccine of Brucella meliteusis

A Brucella and production method technology, applied in the directions of antibacterial drugs, bacterial antigen components, etc., can solve the problems of low freeze-drying survival rate, difficult storage, transportation and use in remote areas, poor protection function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] - vaccine preparation

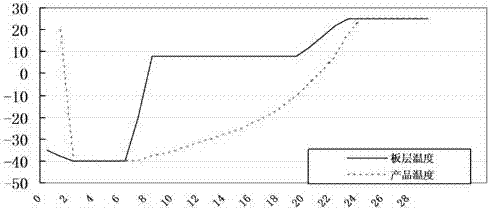

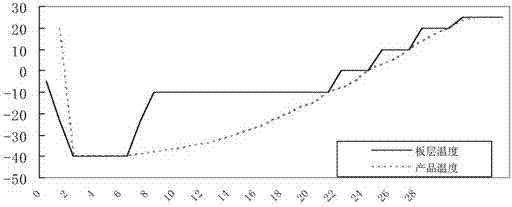

[0068] Brucella suis (CVCC70502 strain) seed liquid is inoculated in the liquid culture medium provided by the present invention by 1%~2% of culture medium total amount, 37 ℃ of fermentations or aerated culture 30~36h, in the cultivation process according to It is necessary to add an appropriate amount of antifoaming agent, and add an appropriate amount of sterilized 40% glucose to control the pH value according to the increase in pH. After the cultivation, centrifuge at 4500r / min for 20min, remove the supernatant, immediately add the sterilized and preheated to 37°C heat-resistant freeze-drying protective agent provided by the present invention, mix well, and dispense according to the regulations. Should pay attention to insulated and shaken evenly in the subpackaging process, and carry out freeze vacuum drying rapidly, press the method that " Chinese Veterinary Pharmacopoeia " stipulates, use freeze-drying curve 2 that the present invention pro...

Embodiment 2

[0070] --Product testing

[0071] Appearance Off-white spongy loose mass, easy to separate from the bottle wall, dissolve quickly after adding diluent.

[0072] The pure test was carried out according to the method stipulated in the "Chinese Veterinary Pharmacopoeia", all of which were pure.

[0073] Sampling for variation test, dilute the vaccine appropriately and inoculate with trypsin On the agar plate, culture at 37°C for at least 72 hours, and check with Brucella colony crystal violet staining method, and the rough colonies do not exceed 5%.

[0074] Viable bacteria counts are marked according to the bottle label, with trypsin Count the live bacteria on the agar plate (according to the method stipulated in the "Chinese Veterinary Pharmacopoeia"), and the number of live bacteria in each head should be greater than 1×10 10 CFU.

[0075] In the safety inspection, the head portion should be marked according to the bottle label, and the vaccine should be filled with tryp...

Embodiment 3

[0080] ——Screening of heat-resistant protective agent formula and freeze-drying curve

[0081] Through the freeze-thaw test and freeze-drying test of 10 kinds of protective agent matrices, the applicable concentrations of various protective agent matrices were preliminarily clarified, ascorbic acid (0.2%, 0.1%), vitamin C (0.2%, 0.1%), trehalose (5 %, 7.5%), BSA (0.5%) had the highest bacterial survival rate in the freeze-thaw test; 1.5% PVP + 5% trehalose + 5% mannitol + 1% thiourea could significantly improve the freeze-dried bacterial storage rate, in addition, 1.5% Adding 0.2% vitamin C, 0.2% ascorbic acid, 0.5% BSA, and 0.5% 199 medium to PVP and 5% trehalose can obviously improve the anti-aging effect of bacteria. Based on this, four heat-resistant protective agent formulas 1, 2, 3 and 4 were designed, mixed with Brucella liquid in equal amounts, and freeze-dried by freeze-drying curves 1 and 2 respectively. The results showed that heat-resistant protective agent formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com