Silicon aerogel material preparation method

A silicon aerogel, wet gel technology, applied in the directions of silicon oxide, silicon dioxide, etc., can solve the problems of low mechanical strength and difficult to be widely used, and achieve the effect of enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a silicon airgel material, comprising:

[0030] a), silicate ester, water, auxiliary agent and organic solvent are mixed, carry out hydrolysis reaction under acidic condition, obtain sol;

[0031] The auxiliary agent is one or more of cetyltrimethylammonium bromide, sodium dodecylbenzenesulfonate, sodium dioctylsuccinatesulfonate and sodium glycocholate;

[0032] b), the sol is subjected to polycondensation reaction under alkaline conditions to obtain a wet gel material;

[0033] c) The wet gel material is dried to obtain a silica airgel material.

[0034] In the present invention, the silicate ester, water, auxiliary agent and organic solvent are firstly mixed, and the hydrolysis reaction is carried out under acidic conditions to obtain the sol. Wherein, the silicate is preferably ethyl orthosilicate, more preferably one or more of ethyl orthosilicate-28, ethyl orthosilicate-32 and ethyl orthosilicate-40. The auxiliary a...

Embodiment 1

[0045] Weigh 100g tetraethyl orthosilicate-32 and 800g water into the container, start stirring, and add a certain amount of 1mol / L hydrochloric acid at the same time to adjust the pH value of the system to 4, then slowly add 1000mL of 95wt% alcohol, the alcohol addition process , the vessel temperature was maintained at 30 °C. After the alcohol was added, 100 g of cetyltrimethylammonium bromide was added, and reacted at 40° C. for 2 hours to obtain a silica sol.

[0046] Concentrated ammonia water was slowly added to the above silica sol to adjust the pH of the system to 13, and reacted at 50°C for 24 hours to obtain a wet gel material.

[0047] The wet gel material prepared above was soaked in ethanol and soaked at 50° C. for 24 hours. After soaking, separate the wet gel material and ethanol, put the separated wet gel material into a mixed solution of 100mL hexamethyldisilazane and 1000mL ethanol, and heat at 65°C for 24h.

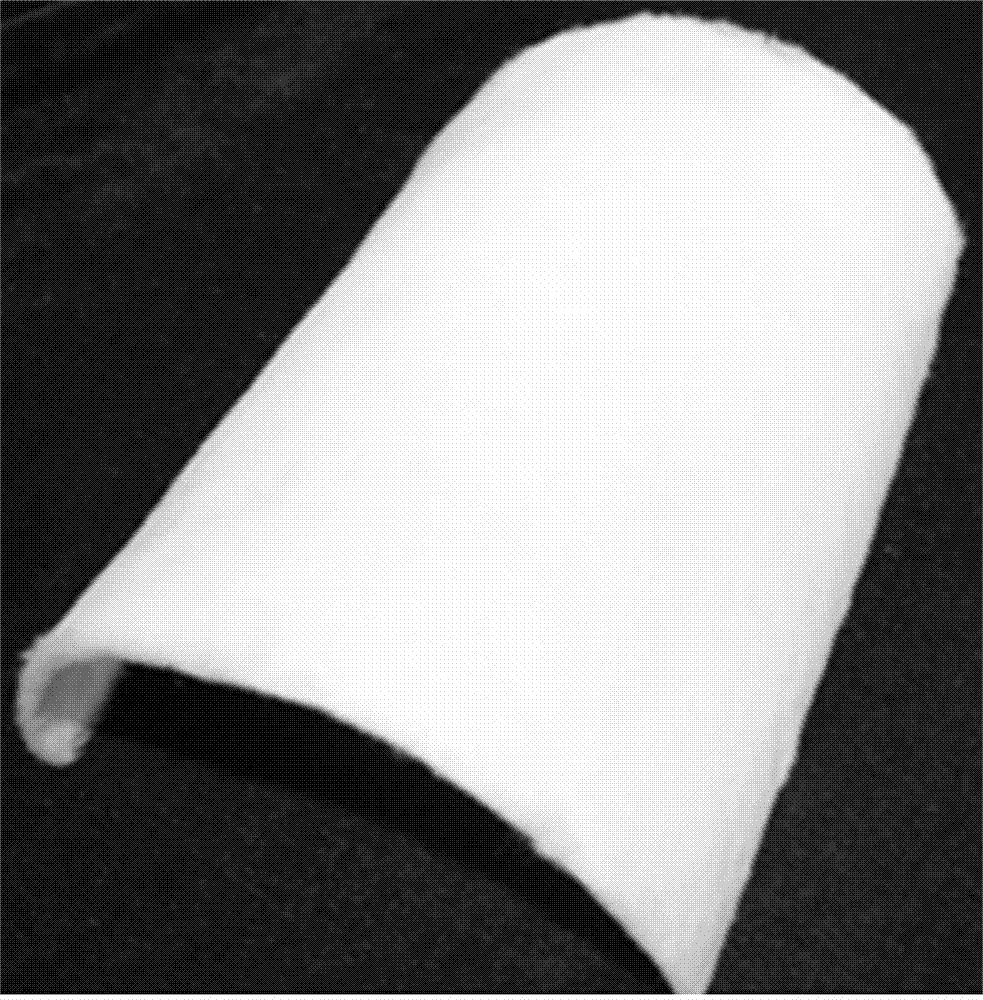

[0048] After heating, take out the wet gel mater...

Embodiment 2

[0052] Weigh 120g of tetraethyl orthosilicate-40 and 900g of water into the container, start stirring, and add a certain amount of 1mol / L hydrochloric acid to adjust the pH value of the system to 3, then slowly add 1200mL of 95wt% alcohol, the alcohol addition process , the vessel temperature was maintained at 32 °C. After the alcohol was added, 120 g of sodium dodecylbenzenesulfonate was added and reacted at 42° C. for 3 h to obtain a silica sol.

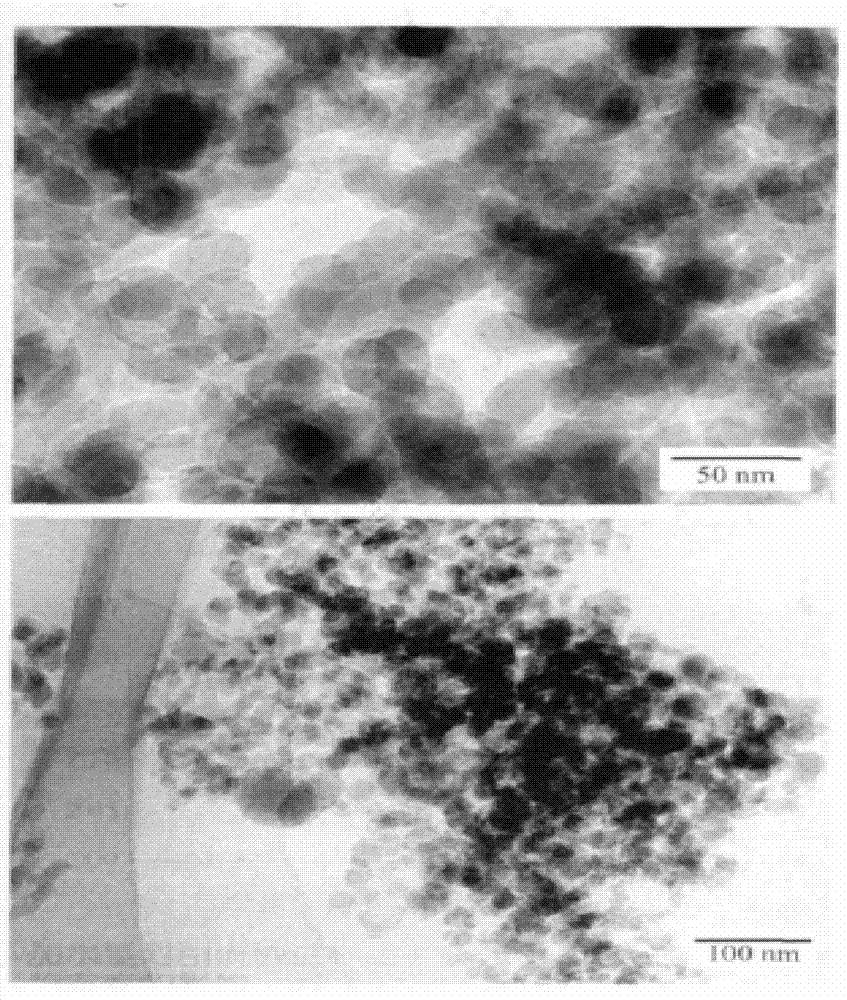

[0053] Slowly add concentrated ammoniacal liquor to the above-mentioned silica sol, adjust the pH value of the system to be 12, add glass fiber needle felt (gram weight: 950g / m 2 , Tensile breaking strength: 1900N / 50mm, Bursting strength: 3.6MPa, Air permeability: 10m 3 / m 2 .min, temperature resistance: 600°C, thickness: 3mm, density: 110kg / m 3 ), so that the needle felt is completely wetted by the solution. After absorbing the mixed solution of silica sol and ammonia water, the needle felt was reacted at 50°C for 16 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com