Rapid synthesis method for high-quantum-yield fluorescent carbon dots

A technology of fluorescent carbon dots and a synthesis method, applied in the fields of chemistry and nanomaterials science, can solve the problems of unfavorable continuous and large-scale production of fluorescent carbon quantum dots, low carbon quantum yield, non-renewable energy, etc. The effect of high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

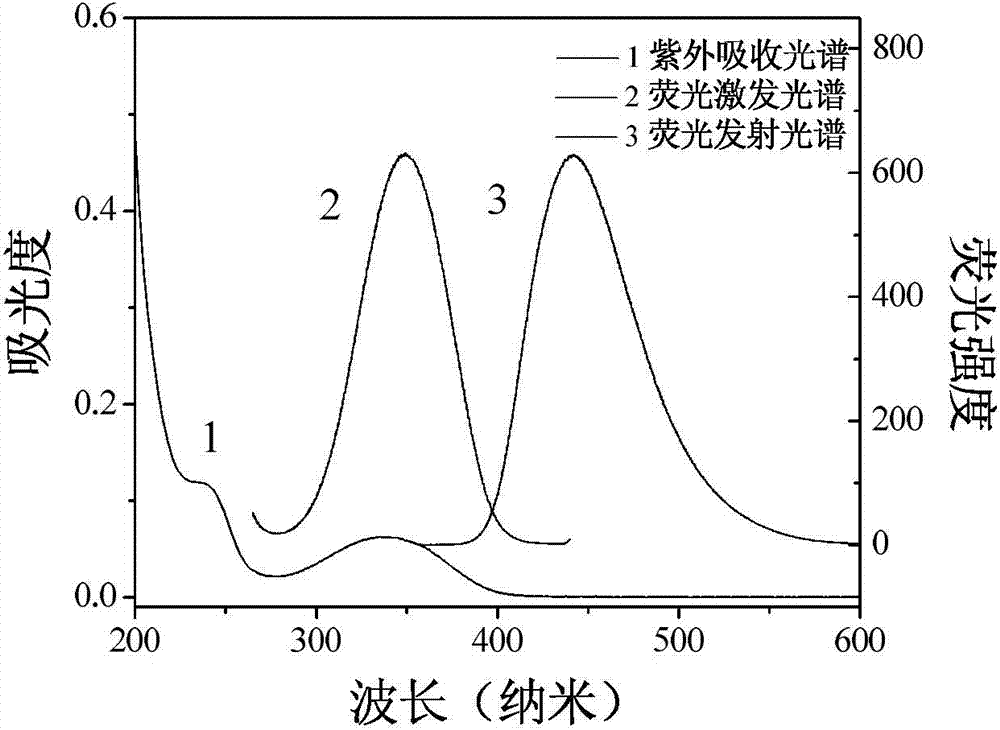

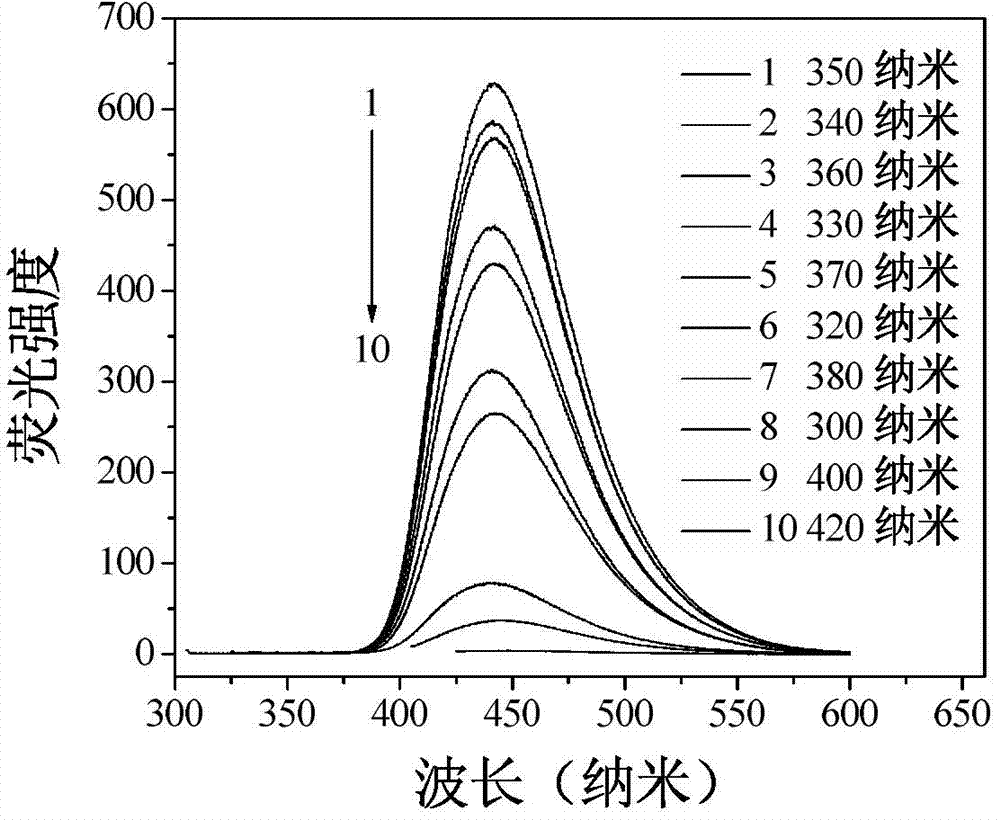

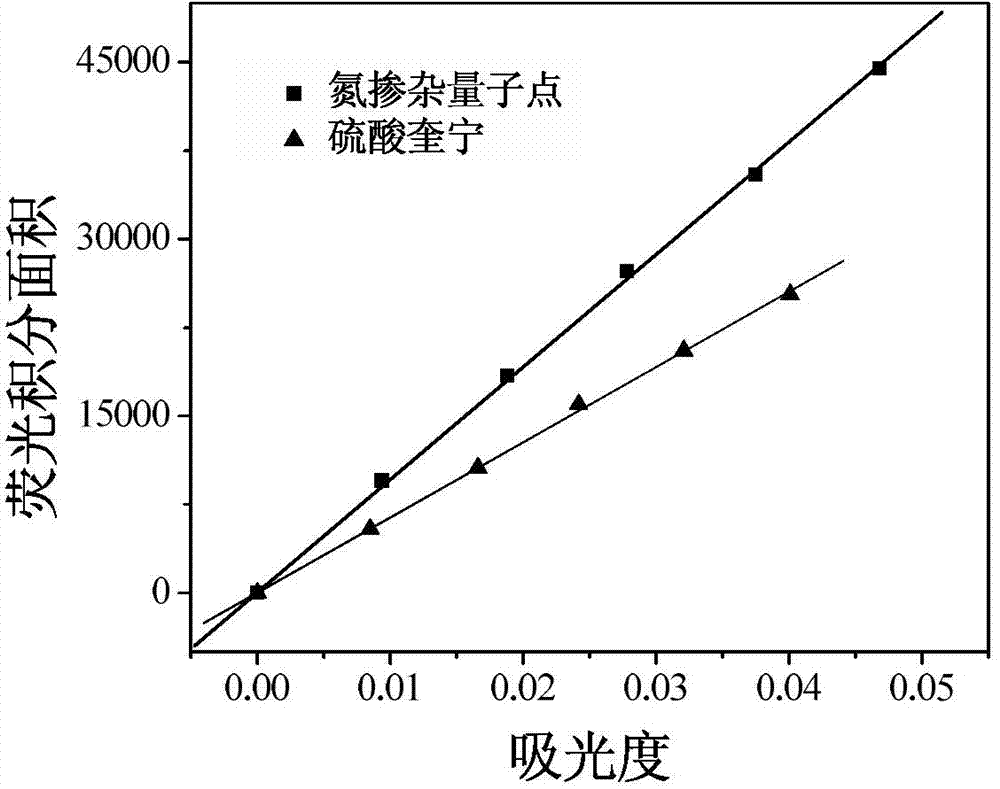

[0028] A kind of fast, the synthetic method of fluorescent carbon dot of high quantum yield, comprises the following steps:

[0029] 1) Mix citric acid monohydrate and ethylenediamine and stir evenly to obtain a mixed solution;

[0030] 2) The mixed solution in step 1) was placed in a microwave reactor model of CEM Discover for reaction, and the temperature was set at 130°C;

[0031] 3) Cool to obtain a brown liquid product, inject the brown liquid product into a dialysis bag for dialysis, the molecular weight of the dialysis bag is 500Da, collect the liquid in the dialysis bag, carry out rotary evaporation and concentration, and freeze-dry the concentrated sample to obtain Fluorescent carbon dots.

[0032] Wherein, the conditions for the rotary evaporation concentration are as follows: the temperature of the rotary evaporator is set at 50° C., and the time of the rotary evaporation is set at 10 minutes.

[0033] Wherein, in the step 3), the solution after the microwave reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com