A particle-reinforced iron-based composite material, ball milling preparation method and application thereof

A technology of iron-based composite materials and composite materials, which is applied in the field of particle-reinforced iron-based composite materials and ball mill preparation. It can solve the problems of difficult repeated use of ball mill materials and in-situ repairs that are difficult to apply on a large scale, and achieve efficient and stable treatment effects. The effect of high reuse rate and wide range of pH adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

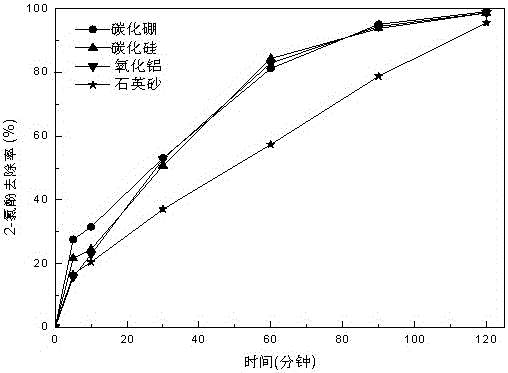

[0029] Example 1: Preparation of SiO with quartz sand as particle reinforcement 2 Reductive Degradation of 2-Chlorophenol Wastewater by -Fe Composite

[0030] (1) According to the mass ratio of iron powder: quartz sand=9:1, weigh 5g of iron powder and quartz sand, and mix them evenly;

[0031] (2) Add the above mixed powder into a 100 mL stainless steel ball mill tank, add 0.3 mL ethanol as a process control agent, and the ball mill medium is stainless steel balls, including 16 large balls (Φ10 mm) and 100 small balls (Φ6 mm) , the ball-milling ratio is 31.2:1, the speed of the planetary ball mill is 550 rpm, and the ball milling is 2 h;

[0032] (3) After ball milling, cool down for 30 minutes until the temperature of the ball mill drops to room temperature, open the ball mill tank to let air in, slowly oxidize the material in the tank for 30 min, and then take out the SiO 2 -Fe composite material;

[0033] (4) SiO obtained above 2 -Fe composite materials were added to 2-ch...

Embodiment 2

[0034] Example 2: Preparation of B with boron carbide as particle reinforcement 4 Reductive Degradation of 2-Chlorophenol Wastewater by C-Fe Composite

[0035] Preparation of B using boron carbide as precursor 4 C-Fe composite material, other conditions are the same as embodiment 1, the difference is that by mass ratio iron powder: boron carbide=9:1, join in the ball mill jar, prepare B 4 C-Fe composites. The dechlorination rate of 2-chlorophenol was 99.1% in 120 min.

Embodiment 3

[0036] Example 3: Preparation of SiC-Fe Composite Material Reductive Degradation of 2-Chlorophenol Wastewater Using Silicon Carbide as Particle Reinforcement

[0037] The SiC-Fe composite material was prepared with boron carbide as the precursor, and the other conditions were the same as in Example 1, except that the mass ratio of iron powder: silicon carbide=9:1 was added to the ball mill tank to prepare the SiC-Fe composite material. The dechlorination rate of 2-chlorophenol was 98.7% in 120 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com