Two-chip brushless DC motor drive control system and control method thereof

A brushed DC motor and drive control technology, applied in the field of servo control, can solve the problems of increasing production cost, long response delay, inability to achieve high-precision control of torque and speed, and achieve the effect of reducing system cost and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

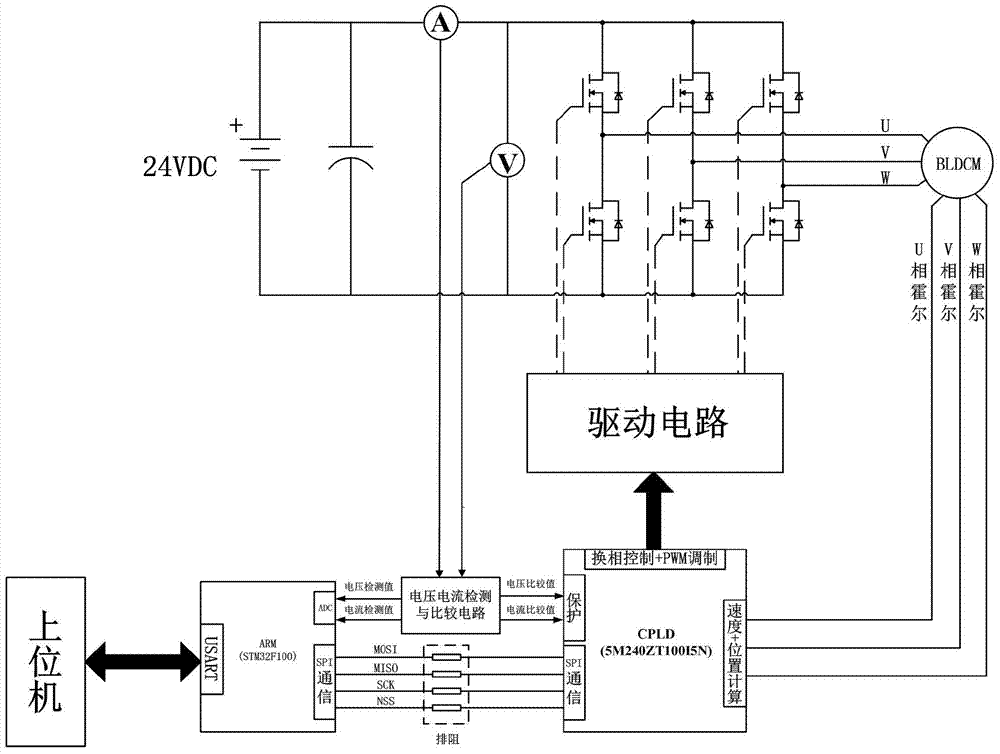

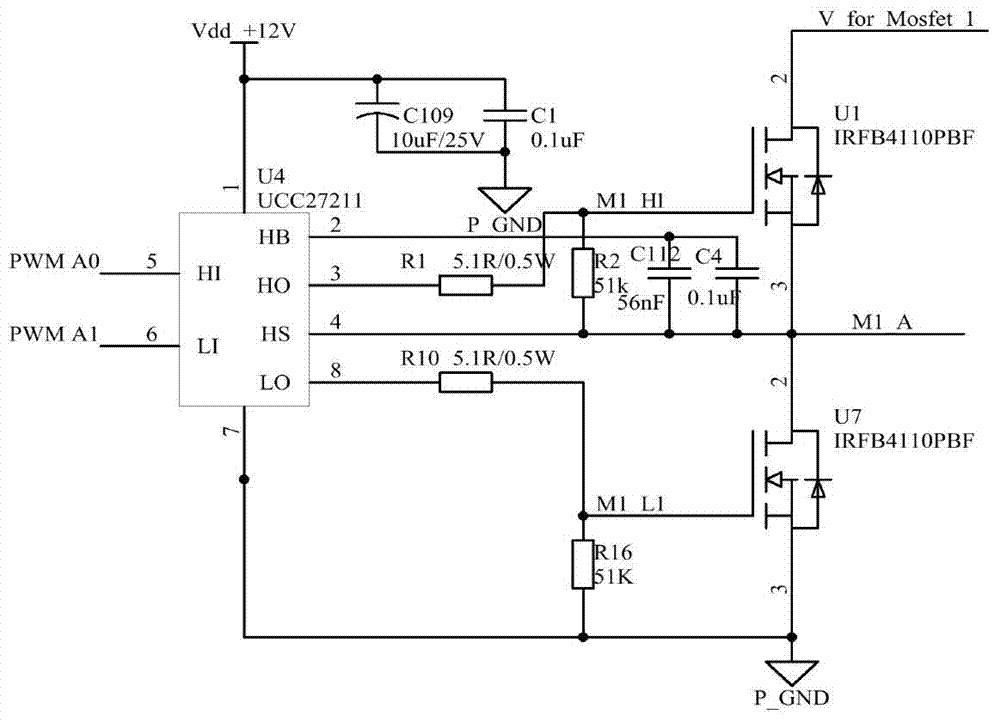

[0049] Such as figure 1 As shown, the brushless DC motor drive control system includes the motor host computer, drive circuit, current detection and comparison circuit, voltage detection and comparison circuit, and control system. The brushless DC motor has a built-in three-phase Hall sensor, and the motor drive circuit is a three-phase phase full bridge circuit.

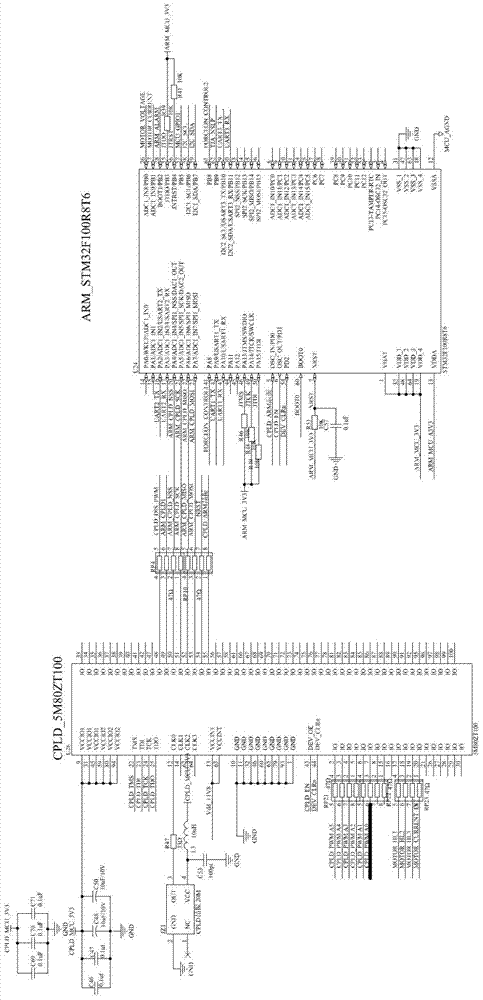

[0050] The control system includes a logical processor connected to each other, a microprocessor, and a drive circuit connected to the logical processor. Such as figure 2 As shown, the logic processor uses a CPLD chip of model 5M240ZT100I5N, and the microprocessor uses an ARM chip of model STM32F100R8T6, and the two communicate through the SPI bus.

[0051] The system does not use position and speed sensors, but uses the position value and speed value of the motor rotor fed back by the Hall sensor inside the brushless DC motor. Since the value fed back by the Hall sensor is not a continuous signal, but only a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com