Preparation method of soybean protein isolate transparent hydrogel with high gel strength and high swelling property

A technology of soybean protein isolate with high strength, which is applied in the field of preparation of transparent hydrogel with high gel strength and high swelling property of soybean protein isolate. , the effect of high charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

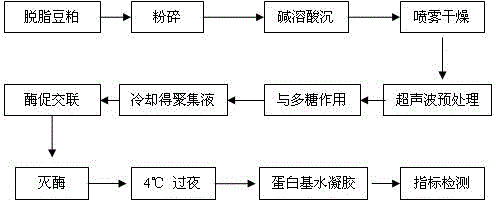

Method used

Image

Examples

Embodiment 1

[0018] 1. Preparation of soybean protein isolate: Prepare soybean protein isolate by alkali-soluble acid precipitation method, add low-temperature defatted soybean meal to distilled water at 1:15 (w / v), and use 2mol L -1 Adjust the pH to 8.0 with NaOH, stir electrically for 4 h at room temperature, centrifuge at 9000 r / min for 20 min, take the supernatant, and use 2 mol·L -1 Adjust the pH to 4.5 with HCl, centrifuge at 4000 r / min for 20 min, take the precipitate, and add the precipitate to distilled water at 1:10 (w / v), 2mol L -1 Adjust the pH to 7.0 with NaOH, fully dissolve, dialyze for 48 hours, and spray-dry to obtain soybean protein isolate powder with a protein content greater than 90%.

[0019] 2. Ultrasonic pretreatment: The above-mentioned soybean protein isolate was prepared into a protein dispersion with a concentration of 5% (w / v), and treated with ultrasonic (20 kHz, 400W) for 60 minutes.

[0020] 3. Preparation of protein / polysaccharide aggregate solution: Diss...

Embodiment 2

[0024] 1. Preparation of soybean protein isolate: Prepare soybean protein isolate by alkali-soluble acid precipitation method, add low-temperature defatted soybean meal to distilled water at 1:15 (w / v), and use 2mol L -1 Adjust the pH to 8.0 with NaOH, stir electrically for 4 h at room temperature, centrifuge at 9000 r / min for 20 min, take the supernatant, and use 2 mol·L -1 Adjust the pH to 4.5 with HCl, centrifuge at 4000 r / min for 20 min, take the precipitate, and add the precipitate to distilled water at 1:10 (w / v), 2mol L -1 Adjust the pH to 7.0 with NaOH, fully dissolve, dialyze for 48 hours, and spray-dry to obtain soybean protein isolate powder with a protein content greater than 90%.

[0025] 2. Ultrasonic pretreatment: The above-mentioned soybean protein isolate was prepared into a protein dispersion with a concentration of 5% (w / v), and treated with ultrasonic (20 kHz, 600W) for 90 minutes.

[0026] 3. Preparation of protein / polysaccharide aggregate solution: Diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com