Zero-valent iron ceramsite and preparation method thereof

A technology of zero-valent iron and ceramsite, which is applied in the direction of adsorption water/sewage treatment, reduced water/sewage treatment, etc., can solve the problems of weak adsorption of ceramsite, instability of zero-valent iron, non-recyclable use, etc., and achieve density The effect of being small, maintaining stability, and maximizing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

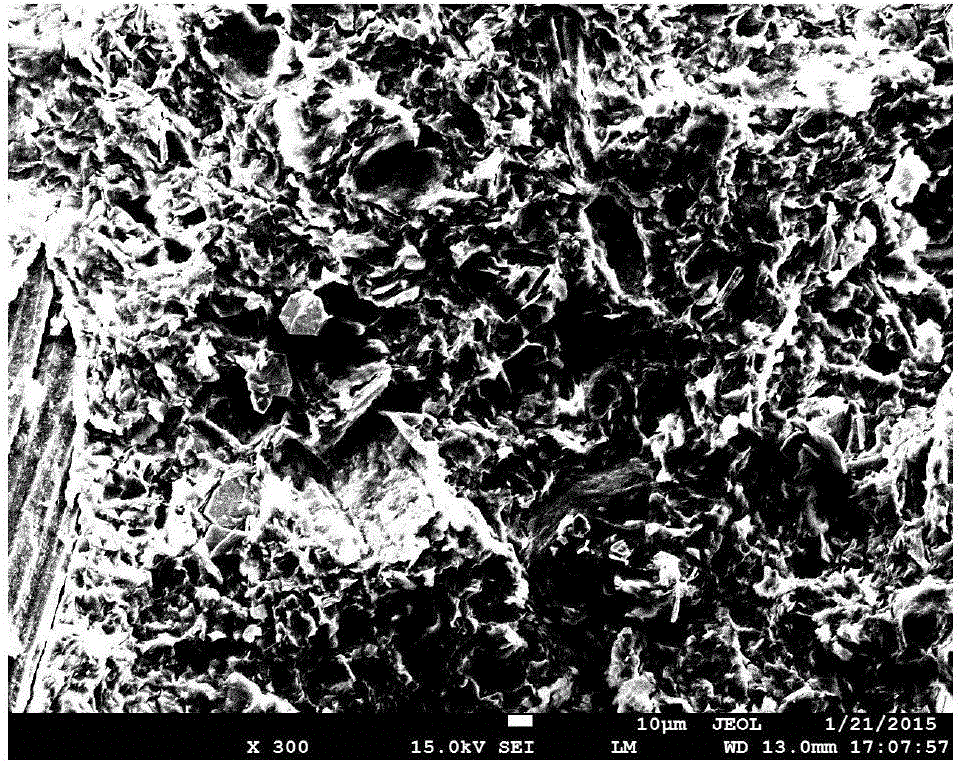

[0039] The preparation method of zero-valent iron ceramsite comprises the following steps: (1) Preparation of ceramsite blank: Weigh 40 parts by weight of construction dregs, 10 parts of rice straw crushed straw and 10 parts of iron oxide and mix to obtain a mixture, press water and The weight ratio of the solid mixture is 1:0.3 and stirred evenly. Among them, the construction dregs are used as the bonding material, the straw is carbonized to form a porous structure, granulated into balls and then sintered, and it is easy to recycle after absorbing nitrogen and phosphorus; (2) Drying and sintering the blank : first air-dry the above-mentioned ceramsite blank, then heat it up, the heating rate is 2°C / min, and then sinter at 500°C for 30min; (3) Reduction of the sintered product: cool the above-mentioned sintered product to room temperature, preferably Cool naturally for 24 hours, and then reduce with 0.4mol / L sodium borohydride solution to obtain zero-valent iron ceramsite. The ...

Embodiment 2

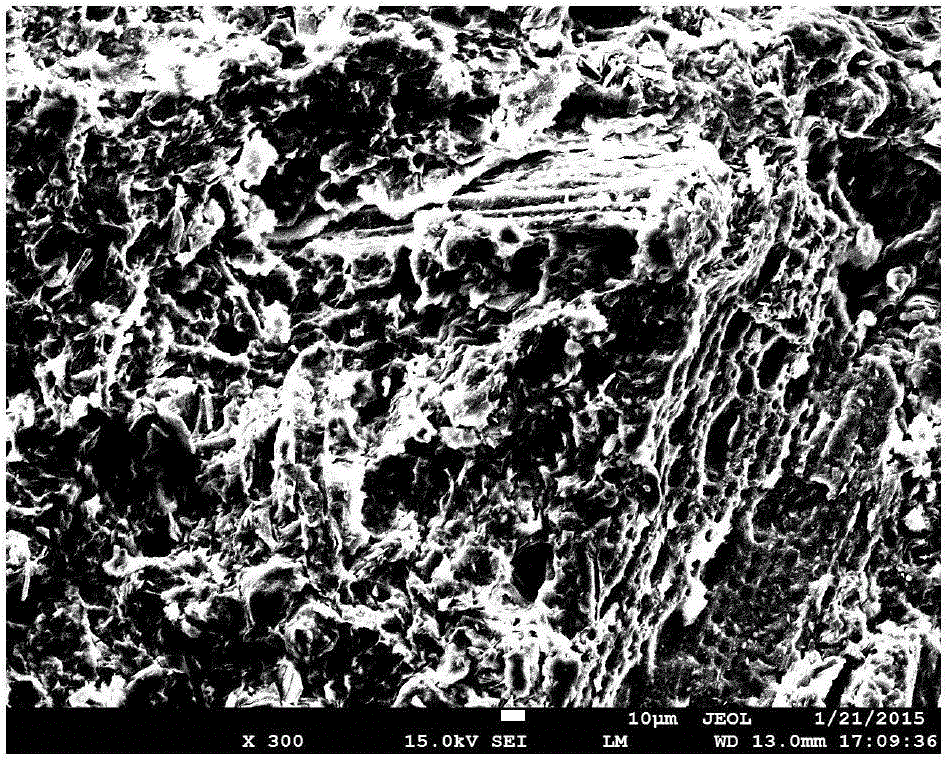

[0041]The preparation method of zero-valent iron ceramsite comprises the following steps: (1) Preparation of ceramsite blank: Weigh 80 parts by weight of construction dregs, 30 parts of crushed rice straw and 30 parts of iron oxide and mix to obtain a mixture. The weight ratio of the solid mixture is 1:0.5 and stirred evenly; (2) Drying and sintering blank: first blow dry the above-mentioned ceramsite blank with nitrogen, then raise its temperature at a rate of 4°C / min, and then sinter at 800°C for 60min (3) Reduction of the sintered product: the above-mentioned sintered product is cooled to room temperature, preferably naturally cooled for 24 hours, and then reduced with 0.5mol / L sodium borohydride solution to obtain zero-valent iron ceramsite, the best reduction time is 4 hours , wherein, the construction dregs include attapulgite, kaolin, bentonite and red soil. The morphology of the obtained zero-valent iron ceramsite is as follows figure 2 As shown, the ceramsite has a ...

Embodiment 3

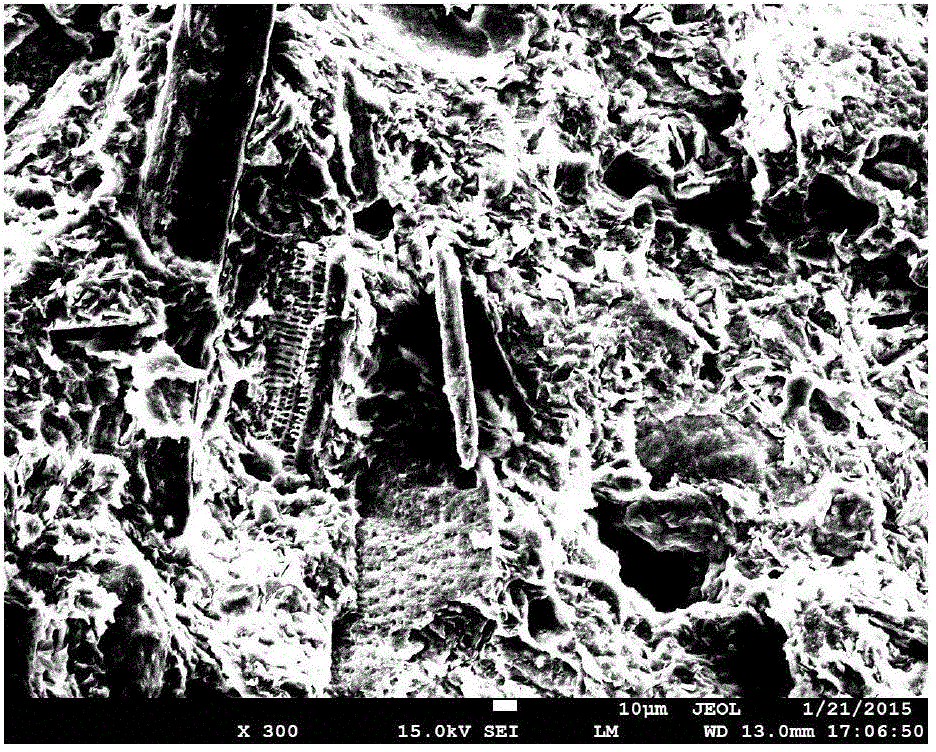

[0043] The preparation method of zero-valent iron ceramsite comprises the following steps: (1) preparation of ceramsite blank: take 60 parts by weight of construction dregs, 20 parts of crushed rice straw and 20 parts of iron oxide and mix to obtain a mixture, press water and The weight ratio of the solid mixture is 1:0.4 and stirred evenly; (2) Drying and sintering the billet: first put the above-mentioned ceramsite billet in an oven to dry, then heat it up at a rate of 3°C / min, and then heat it up at 650°C (3) Reduction of the sintered product: Cool the above sintered product to room temperature, and then reduce it with 0.8mol / L sodium borohydride solution to obtain zero-valent iron ceramsite. The optimal reduction time is 3 hours. The above crushed rice straws can be replaced by any one or more than two kinds of rapeseed, corn, wheat or bean straws. The morphology of the obtained zero-valent iron ceramsite is as follows image 3 As shown, there are uneven pores inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com