Titanium dioxide with core-shell structure constructed by nanosheets and its preparation method and application

A technology of core-shell structure and titanium dioxide, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of limited application, facilitate storage and penetration, improve structural stability, and improve monodispersity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

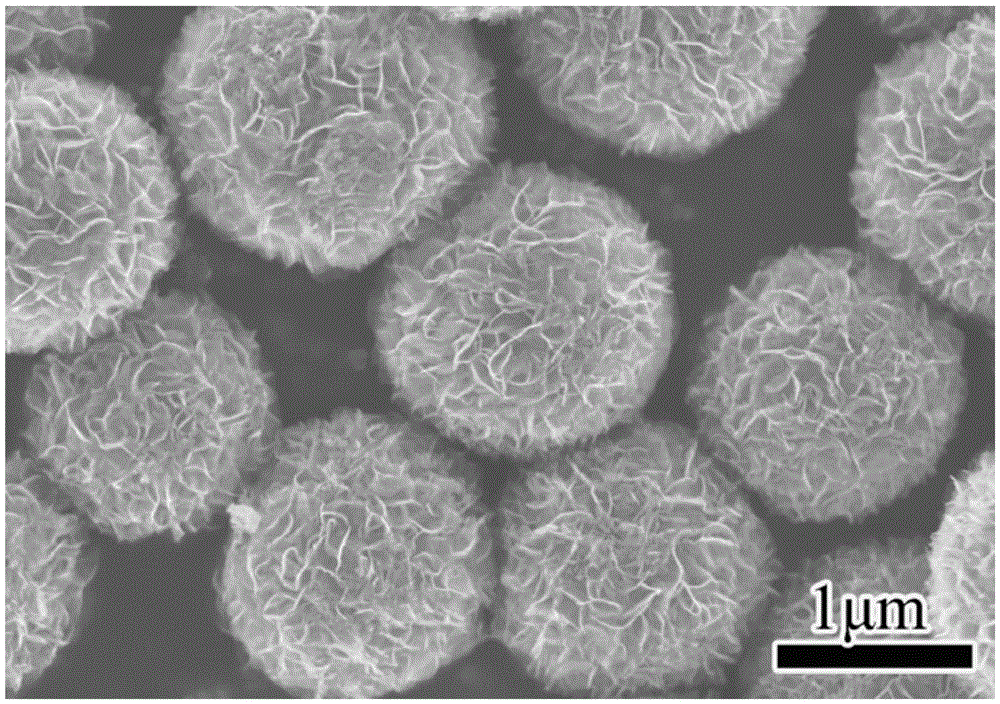

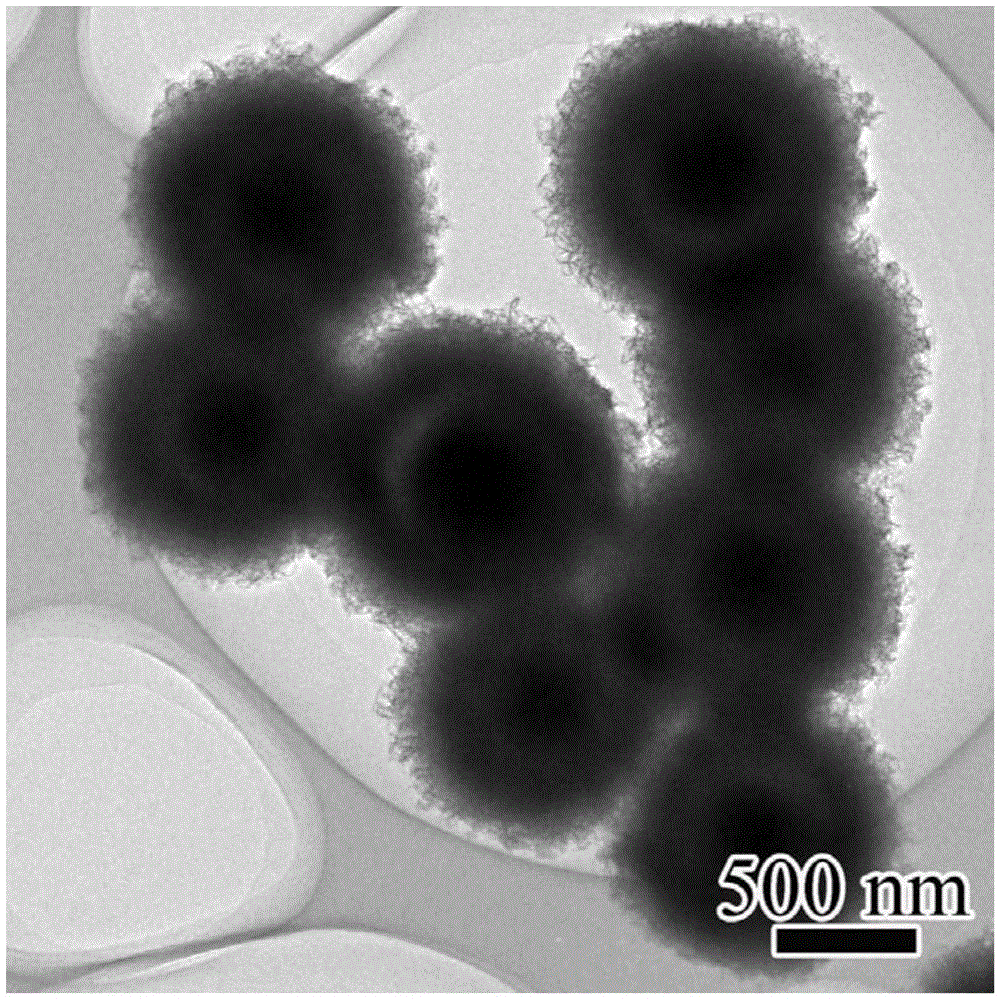

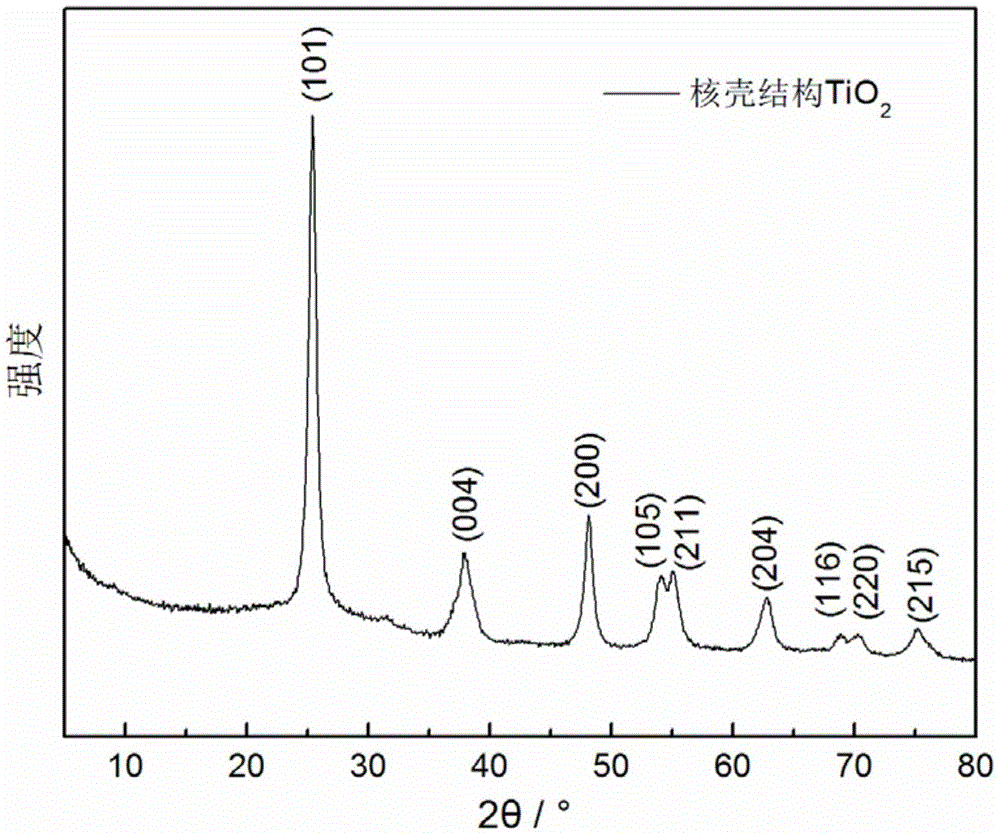

[0039] Add 0.12 mL of tetraethylenepentamine into 84 mL of isopropanol, stir evenly, then add 3 mL of tetraisopropyl titanate into the above solution, and stir for 30 minutes. The above solution was transferred to a 150mL reactor and reacted at 200°C for 24 hours. Then the obtained product is repeatedly washed with ethanol, centrifuged, dried, and roasted at 400° C. for 2 hours to obtain the core-shell structure titanium dioxide constructed by nanosheets.

[0040] During this process, nanoparticles are formed first, and the nanoparticles agglomerate to form larger spherical particles. At the same time, under the action of the surfactant, a nanosheet structure is formed on the surface of the spherical particle. Then, after the Ostwald ripening process, the shell structure of the nanosheets continues to grow, the core structure continues to decrease, and an obvious cavity is formed between the two, and the required special structure of "core-cavity-shell" can be obtained. The ...

Embodiment 2

[0044] Add 0.03mL of tetraethylenepentamine into 84mL of isopropanol, stir evenly, then add 3mL of tetraisopropyl titanate into the above solution, and stir for 30 minutes. The above solution was transferred to a 150mL reactor and reacted at 200°C for 24 hours. Then the obtained product is washed with ethanol, centrifuged, dried, and calcined at 400° C. for 2 hours to obtain titanium dioxide with a core-shell structure constructed of nanosheets.

Embodiment 3

[0046] Add 0.06mL of tetraethylenepentamine into 84mL of isopropanol, stir evenly, then add 3mL of tetraisopropyl titanate into the above solution, and stir for 30 minutes. The above solution was transferred to a 150mL reactor and reacted at 200°C for 24 hours. Then the obtained product is washed with ethanol, centrifuged, dried, and calcined at 400° C. for 2 hours to obtain titanium dioxide with a core-shell structure constructed of nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com