Depression-preventing low-swell-shrinking mirror plate

An anti-sag, expansion and contraction technology, applied in heating inorganic powder coating and other directions, can solve the problems of mirror plate failure, surface depression, no depression, etc., to improve the surface strength, improve the expansion range, overcome the effects of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

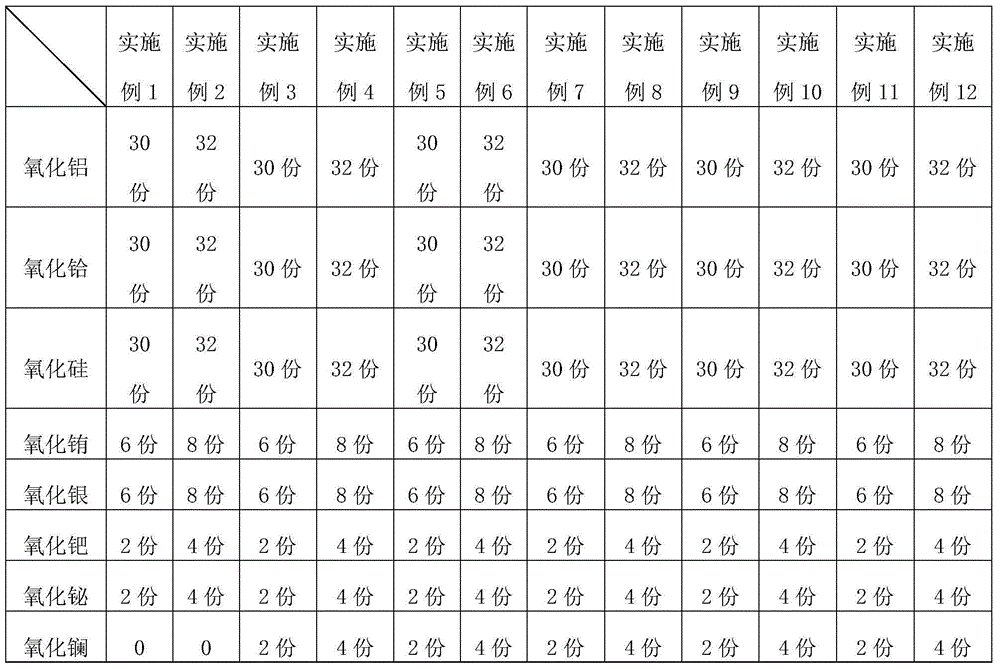

[0016] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

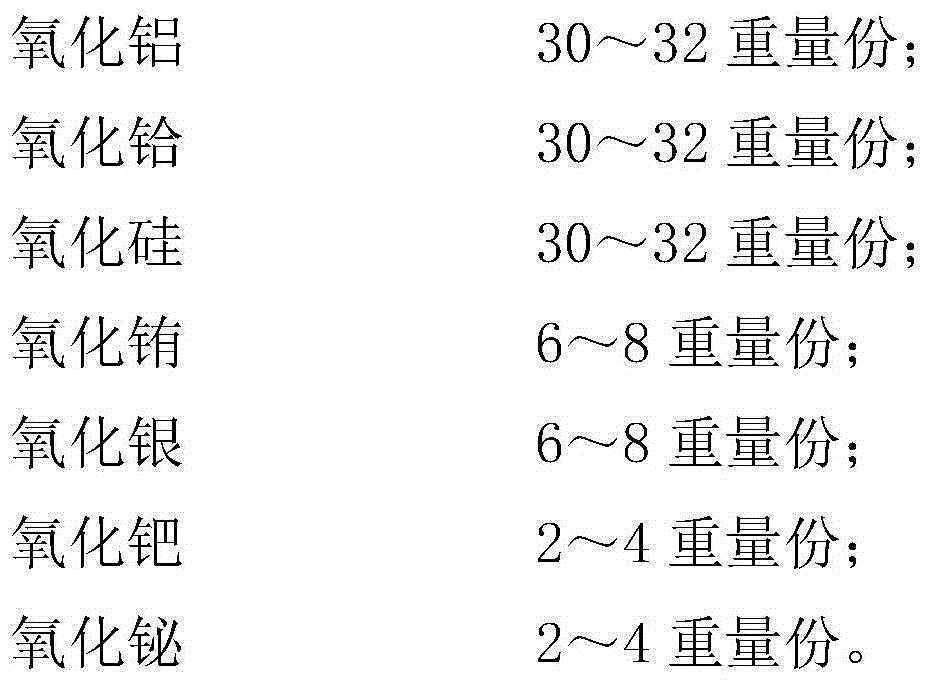

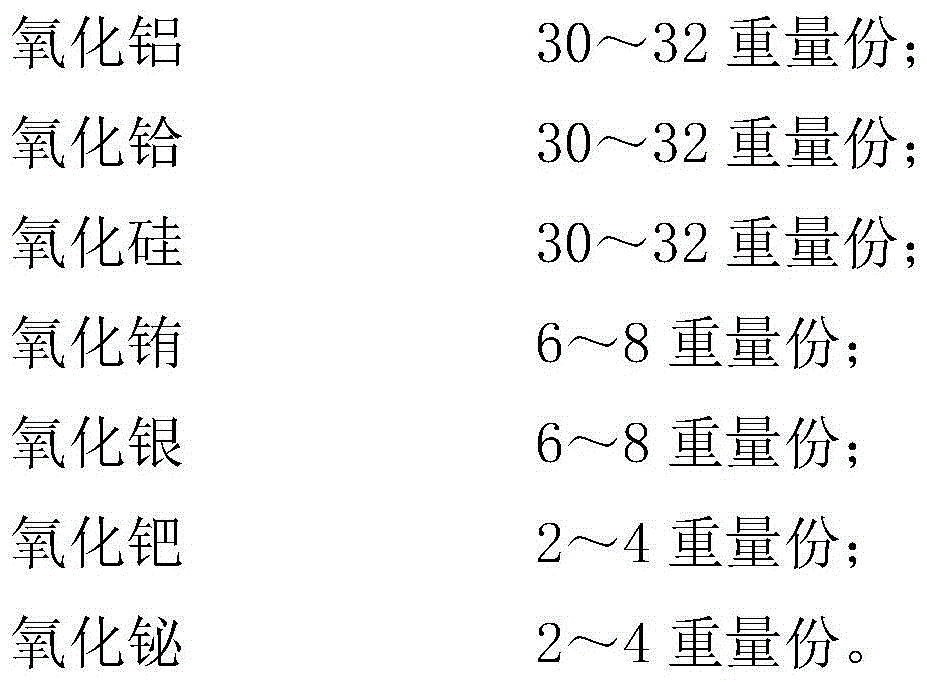

[0017] This case proposes an embodiment of an anti-sag low-expansion mirror plate, which uses a stainless steel plate as a base material, and a coating is provided on the surface of the stainless steel plate, and the coating includes the following fine powder materials in parts by weight:

[0018]

[0019] The material used in this case can preferably select nano-scale powder or micron-scale powder for use.

[0020] As another embodiment of the present application, wherein, the coating further includes 2-4 parts by weight of lanthanum oxide. Lanthanum oxide can improve the mechanical strength, hardness and impact resistance of the coating at high temperatures, but it should be noted that the amount of lanthanum oxide added should be limited. If the amount of lanthanum oxide added is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com