Method for recovering sapphire substrate

A sapphire substrate and sapphire technology, applied in the field of optoelectronics, can solve the problems of high production cost and complicated etching process, and achieve the effects of short recovery period, low cost and remarkable removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

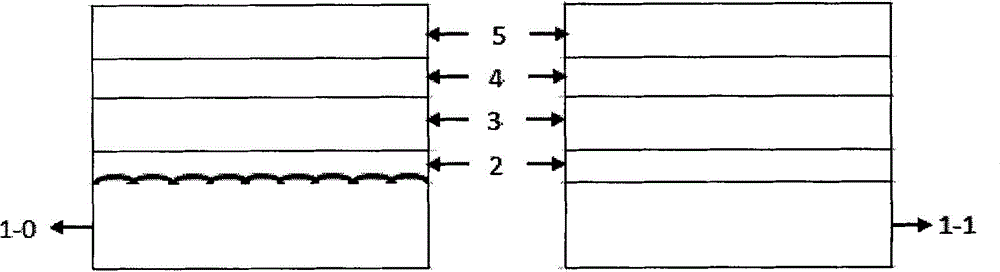

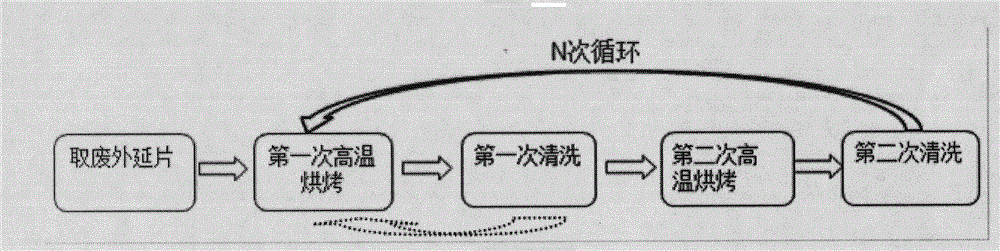

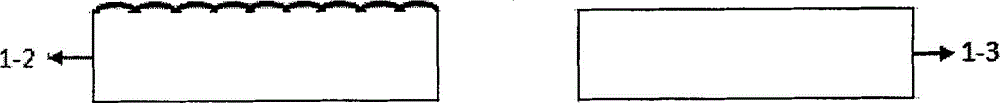

[0044] Such as figure 2 Shown, a kind of method of reclaiming sapphire substrate comprises steps as follows:

[0045] (1) get waste epitaxial wafer,

[0046] Receive waste epitaxial wafers, check the number of wafers, and check whether the wafers are complete;

[0047] (2) The first high temperature baking,

[0048] Put the waste epitaxial wafer into a high-temperature baking furnace for the first high-temperature baking. The baking time is 2.5 hours, the baking temperature is 850°C, and the atmosphere in the baking room is a mixture of nitrogen and hydrogen. Among them, hydrogen occupies The volume ratio is 0.5%;

[0049] (3) the first cleaning,

[0050] The epitaxial wafer after the above-mentioned step (2) baking is cleaned for the first time, and the etching solution for the first cleaning is a mixed solution of sulfuric acid and hydrogen peroxide, the concentration of sulfuric acid is 95%, and the volume ratio of sulfuric acid and hydrogen peroxide is 3:4, corrosion t...

Embodiment 2

[0059] A kind of method for reclaiming sapphire substrate as described in embodiment 1, its difference is,

[0060] The baking time in step (2) is 8 hours, the baking temperature is 1200°C, and the volume occupied by hydrogen is 5%;

[0061] The corrosion solution described in step (3) is a mixed solution of phosphoric acid and hydrogen peroxide, the concentration of phosphoric acid is 90%, the volume ratio of phosphoric acid and hydrogen peroxide is 2: 3, and the corrosion time is 10 minutes;

[0062] The baking time in step (4) is 8 hours, the baking temperature is 1200° C., and the volume ratio of ammonia gas is 4%;

[0063] The second cleaning described in step (5) is first cleaned with a mixed solution of phosphoric acid and hydrogen peroxide, wherein the concentration of phosphoric acid is 87%, the volume ratio of phosphoric acid and hydrogen peroxide is 1:3, and the corrosion time is 15 minutes; Mixed liquid cleaning, wherein the concentration of ammonia water is 68%, ...

Embodiment 3

[0065] A kind of method for reclaiming sapphire substrate as described in embodiment 1, its difference is,

[0066] The baking time in step (2) is 15 hours, the baking temperature is 1600° C., and the volume occupied by hydrogen is 15%;

[0067] The corrosion solution described in step (3) is a mixed solution of nitric acid and hydrogen peroxide, the concentration of nitric acid is 82%, the volume ratio of nitric acid and hydrogen peroxide is 3: 2, and the corrosion time is 20 minutes;

[0068] The baking time in step (4) is 14 hours, the baking temperature is 2000°C, and the volume ratio of ammonia is 15%;

[0069] The second cleaning described in step (5) is first cleaned with a mixed solution of nitric acid and hydrogen peroxide, wherein the concentration of nitric acid is 80%, the volume ratio of phosphoric acid and hydrogen peroxide is 2: 1, and the corrosion time is 20 minutes; Mixed liquid cleaning, wherein the concentration of ammonia water is 89%, the mixing ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com