Preparation method for sodium aescinate freeze-dried emulsion for injection

A technology of sodium aescinate and freeze-dried emulsion, which is applied in the direction of freeze-dried transportation, medical preparations containing active ingredients, drying, etc., and can solve the problem of low content of sodium aescinate, instability of aescinate, and influence on curative effect, etc. problem, to achieve the effect of good resolubility, less irritation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

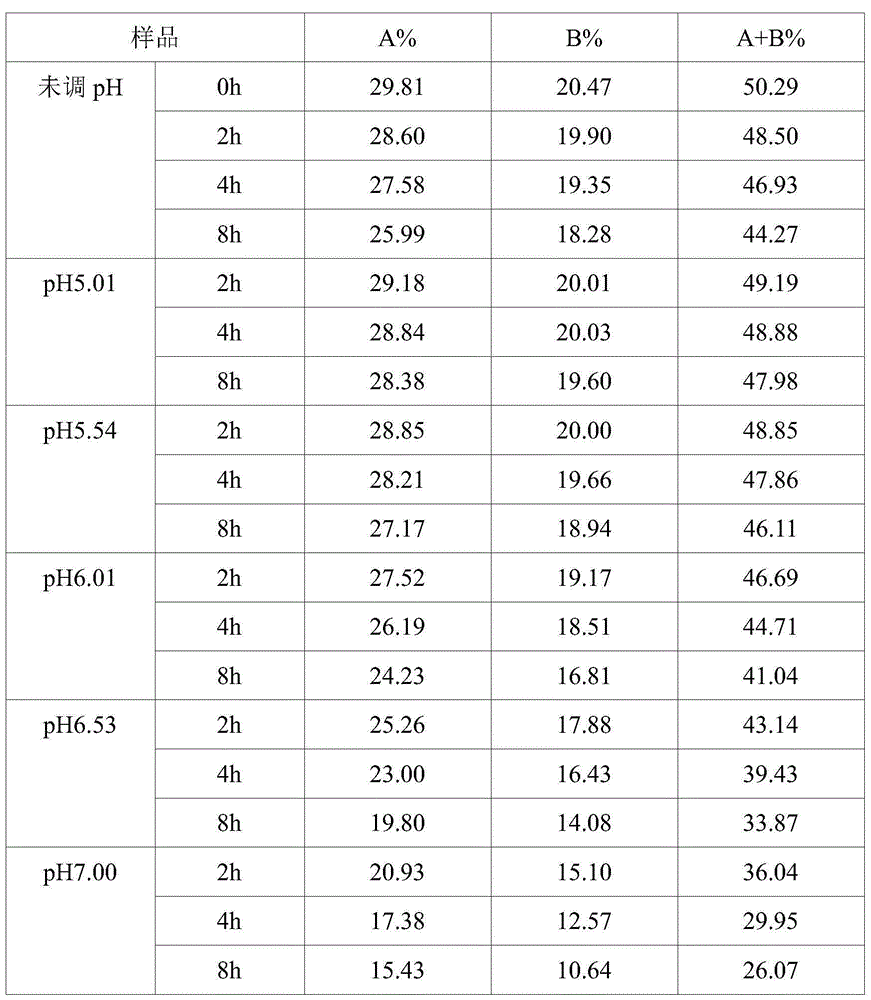

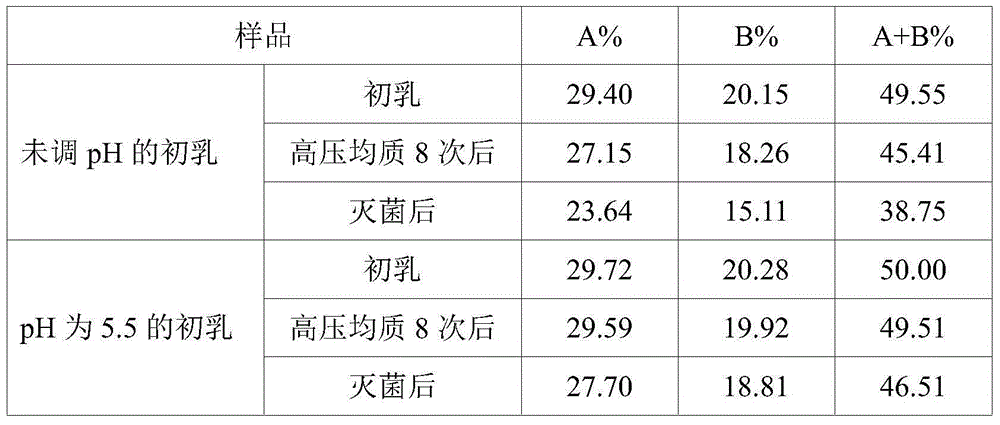

Method used

Image

Examples

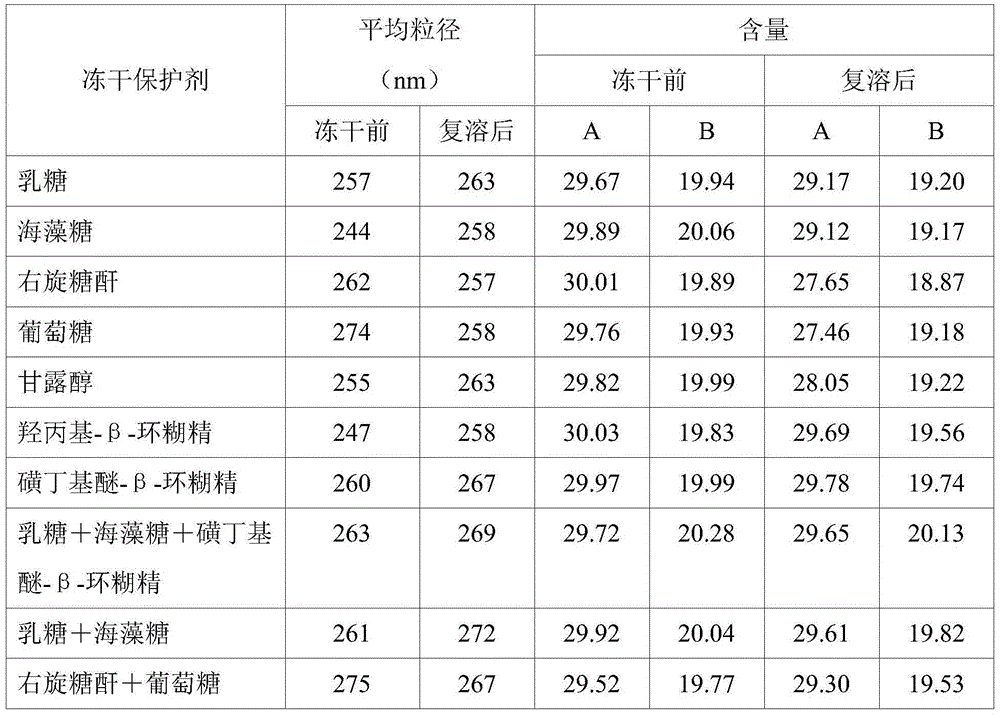

Embodiment 1

[0022] A preparation method of sodium aescinate freeze-dried emulsion for injection: 2g sodium aescinate is dissolved in 20ml acetone, then added to 100ml soybean oil for injection together with 6g lecithin and 0.15g oleic acid, stirred evenly, and then Remove acetone by rotary evaporation to obtain the oil phase; dissolve 12g glycerin and 0.025g EDTA-2Na in 400ml water for injection to obtain the water phase; add the oil phase to the water phase and shear at 70°C and 8000rpm 30min to obtain colostrum; adjust the pH of colostrum to 5, and homogenize 8 times under 800bar pressure to obtain emulsion; take 80g of lyoprotectant (lactose 24g, trehalose 40g, sulfobutyl ether-β-cyclodextrin 16g) into the homogeneous emulsion, stirred until the lyoprotectant is completely dissolved, then filtered through a 0.22 μm filter membrane, subpackaged, and lyophilized to obtain the product.

[0023] Described freeze-drying comprises the following steps:

[0024] 1) Pre-freezing: place the fil...

Embodiment 2

[0028] A preparation method of sodium aescinate freeze-dried emulsion for injection: 0.1g sodium aescinate is dissolved in 10ml tetrahydrofuran, then added to 50ml olive oil together with 2g lecithin and 0.05g oleic acid, stirred evenly, and then rotated Remove tetrahydrofuran by evaporation to obtain an oil phase; dissolve 5g glycerin and 0.01g EDTA-2Na in 200ml water for injection to obtain a water phase; add the oil phase to the water phase and cut for 60min at 80°C and 3000rpm , to obtain colostrum; adjust colostrum pH to 6, and homogenize 10 times under 600bar pressure to obtain emulsion; get 25g lyoprotectant (lactose 12.5g, trehalose 7.5g, sulfobutyl ether-β-cyclodex 5g of essence) was added to the homogeneous emulsion, stirred until the freeze-dried protective agent was completely dissolved, then filtered through a 0.1 μm filter membrane, subpackaged, and freeze-dried to obtain final product.

Embodiment 3

[0030] Dissolve 5g of sodium aescinate in 50ml of acetone, then add it together with 10g of lecithin and 0.35g of oleic acid into 200ml of oil for injection, stir evenly, then remove the acetone by rotary evaporation to obtain the oil phase; mix 20g of glycerin, 0.05g of EDTA -2Na was dissolved in 600ml of water for injection to obtain the water phase; the oil phase was added to the water phase, and sheared at 40°C for 10 minutes at a speed of 12000rpm to obtain colostrum; the pH of the colostrum was adjusted to 7, and the Homogenize 5 times under pressure to obtain an emulsion; take 150g of lyoprotectant (lactose 30g, trehalose 75g, sulfobutyl ether-β-cyclodextrin 45g) into the homogenized emulsion, stir until freeze-dried The protective agent is completely dissolved, then filtered through a 0.5 μm filter membrane, subpackaged and freeze-dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com