Acrylate emulsion of water-based ink for soft PVC (Polyvinyl Chloride) and preparation method thereof

An acrylate and water-based technology, which is applied to the acrylate emulsion of soft PVC water-based ink and its preparation field, can solve the problems affecting the stability and printing effect of water-based ink, poor adhesion of printing substrates, poor color paste compatibility, etc. problem, to achieve the effect of increased strength, improved adhesion, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

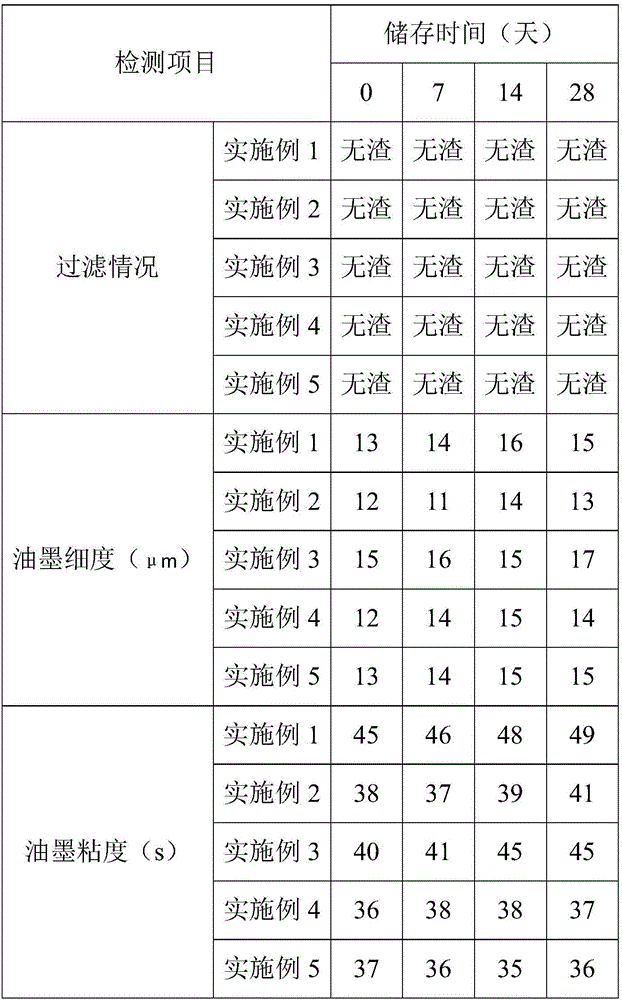

Examples

Embodiment 1

[0035] Take 15 parts of methyl acrylate, 10 parts of ethyl acrylate, 10 parts of methyl methacrylate and 8 parts of methacrylic acid and mix uniformly to obtain mixture A; 10 parts of butyl acrylate, 10 parts of vinyl acetate, methyl methacrylate Mix 6 parts with 1.2 parts of ethylene glycol diacrylate to obtain mixture B; 15 parts of butyl acrylate, 15 parts of methyl methacrylate and 1.2 parts of ethylene glycol diacrylate to obtain mixture C, set aside.

[0036] Add 200 parts of deionized water to the reactor, raise the temperature of the reactor to 83, then add 3 parts of 1-allyloxy-2-hydroxypropanesulfonate sodium, stir for five minutes and then add ammonium persulfate 0.35 servings.

[0037] Add the mixture A into the reaction kettle dropwise, and control the dropping within 1.5 to 2.5 hours. After holding the heat for half an hour, add 8.5 parts of 22% ammonia water at one time, and continue stirring for ten minutes.

Embodiment 2

[0041] Take 12 parts of ethyl acrylate, 15 parts of hydroxyethyl methacrylate, 3 parts of methyl methacrylate, 9 parts of ethyl methacrylate, and 10 parts of acrylic acid to obtain mixture A; 4 parts of methyl acrylate, ethyl acrylate 10 parts of butyl methacrylate, 5 parts of butyl methacrylate, 2 parts of methyl methacrylate, 5 parts of ethyl methacrylate, 0.5 parts of dicyclopentyl acrylate, and 1.4 parts of diethylene glycol diacrylate were mixed uniformly to obtain mixture B ; 18 parts of butyl acrylate, 2 parts of ethylene tertiary carbonic acid, 5 parts of methyl methacrylate, 1 part of styrene, 0.5 parts of dicyclopentyl acrylate, 0.5 parts of 1,3-butanediol diacrylate to obtain mixture C ,spare.

[0042] Add 185 parts of deionized water into the reactor, raise the temperature of the reactor to 85°C, then add 0.5 parts of allyl polyether sodium sulfate, 2.7 parts of allyl phenoxy polyether ammonium sulfate, and stir for five Minutes later, 0.45 parts of ammonium persu...

Embodiment 3

[0047] Take 8 parts of hydroxyethyl acrylate, 7 parts of hydroxypropyl acrylate, 14 parts of hydroxypropyl methacrylate, 2 parts of methyl methacrylate, 10 parts of sodium p-styrenesulfonate, 6 parts of itaconic acid, fumarate Mix 7 parts of monobutyl acrylate to obtain mixture A; 12 parts of tert-butyl acrylate, 9 parts of isooctyl methacrylate, 6 parts of methyl methacrylate, 1 part of styrene, 1.5 parts of ethylene glycol diacrylate, Mix 0.6 parts of polyethylene glycol diacrylate to obtain mixture B; 14 parts of tert-butyl acrylate, 8 parts of butyl methacrylate, 6 parts of ethyl methacrylate, and 1 part of ethylene glycol diacrylate to obtain mixture C. spare.

[0048] Add 220 parts of deionized water into the reactor, raise the temperature of the reactor to 80°C, then add 3.8 parts of sodium vinylsulfonate, stir for five minutes and then add 0.5 parts of sodium persulfate.

[0049] Add the mixture A into the reaction kettle dropwise, and control the dropping within 1.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com