Preparation method for titanium-containing hierarchical porous structure mesoporous molecular sieve catalyst

A technology of mesoporous molecular sieve and titanium-silicon molecular sieve is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve deep desulfurization, beneficial to industrial production, and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

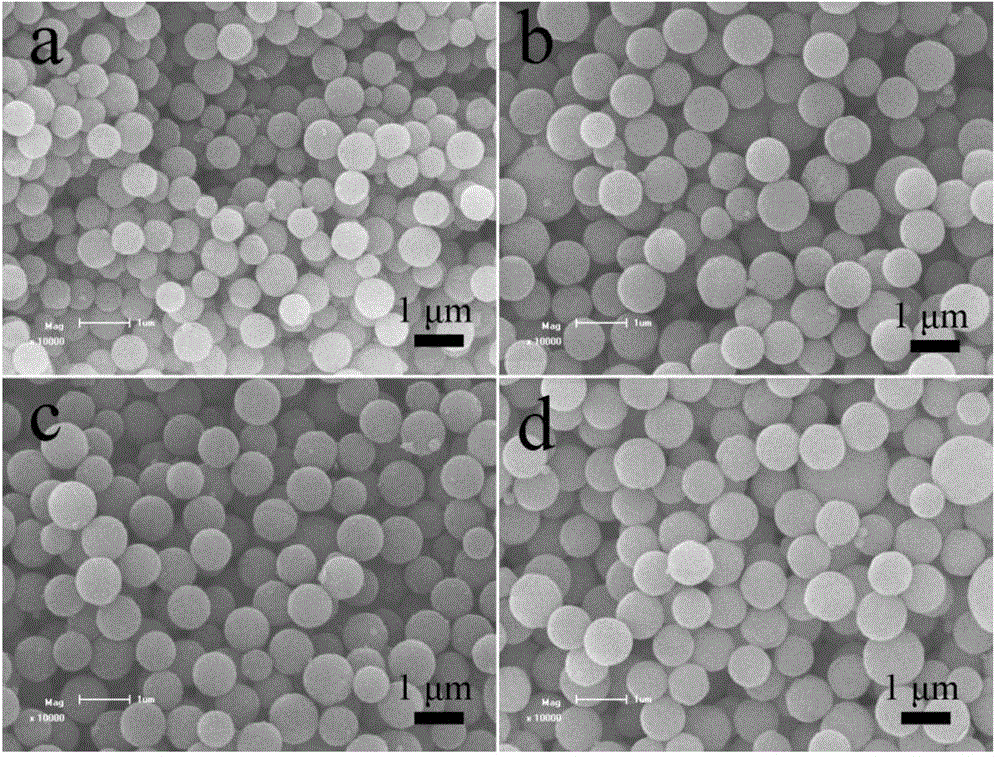

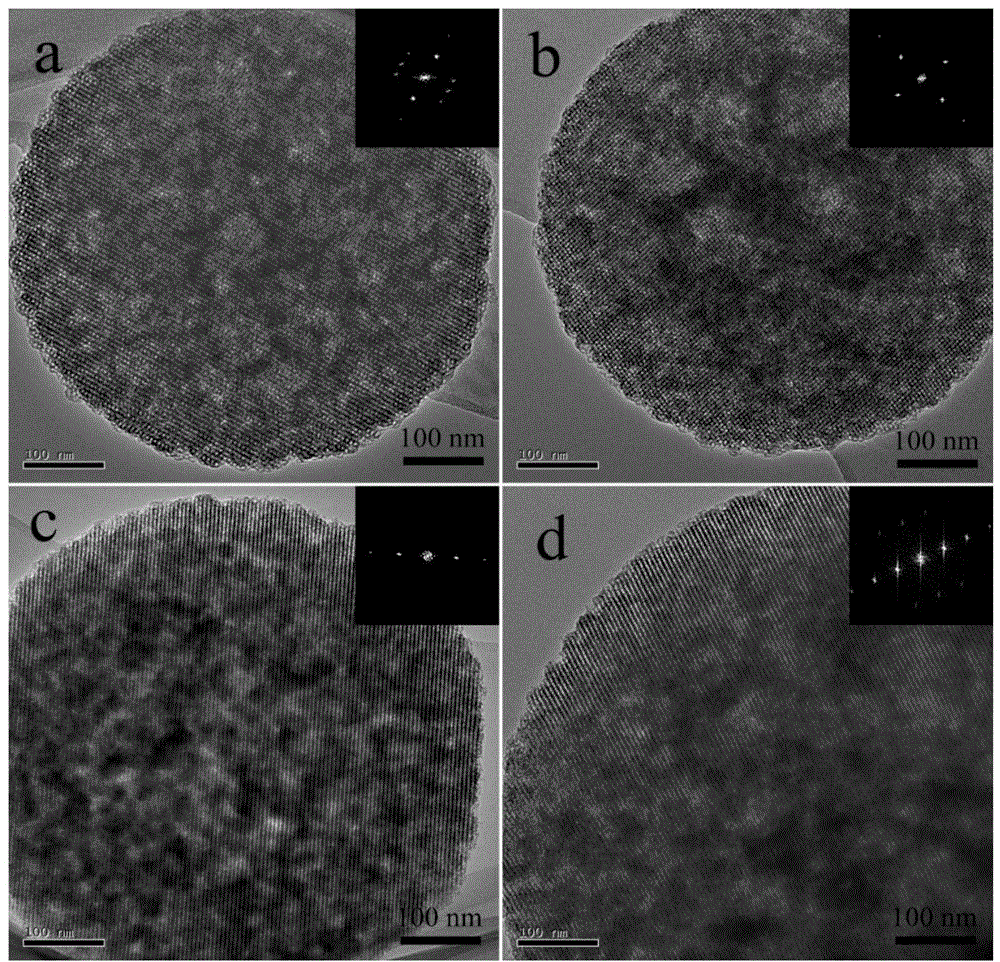

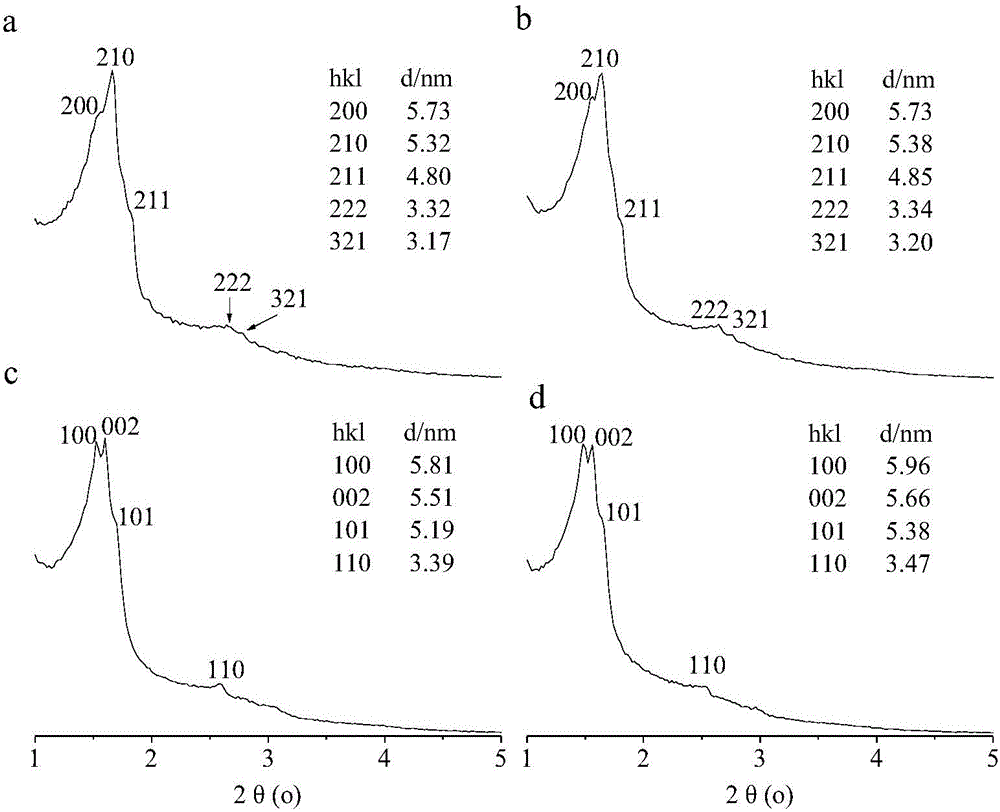

[0022] A preparation method of titanium-containing hierarchical porous structure mesoporous molecular sieve catalyst, using peroxotitanic acid as titanium source, cationic surfactant cetyltrimethylammonium bromide (CTAB) and anionic polyelectrolyte (PAA) The formed mesoscopic complex is used as a dynamic template to synthesize a hierarchically porous mesoporous titanium-silicon molecular sieve. The steps are as follows:

[0023] 1) Preparation of peroxotitanic acid aqueous solution

[0024] Dissolve 0.01 mol of titanyl sulfate hydrate completely in 25 mL of deionized water at room temperature, place the resulting solution in an ice-water bath and stir at 2°C for 30 min, then slowly add 0.04 mol mass percentage concentration of 30% under stirring Hydrogen peroxide aqueous solution, continue to stir 2h in ice-water bath, obtain stable peroxotitanic acid aqueous solution;

[0025] 2) Preparation of Hierarchical Mesoporous Ti-Si Molecular Sieve Catalyst

[0026] Dissolve 0.55 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com