Method for preparing few-layer black scales by ultrasonically stripping black scale

A technology of ultrasonic stripping and black phosphorus flakes, which is applied in the preparation of functional materials and the field of optoelectronic materials, can solve the problems of low purity of black phosphorus, high atmospheric pressure temperature, high energy consumption, etc., and achieve the effect of high quality, less impurities and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

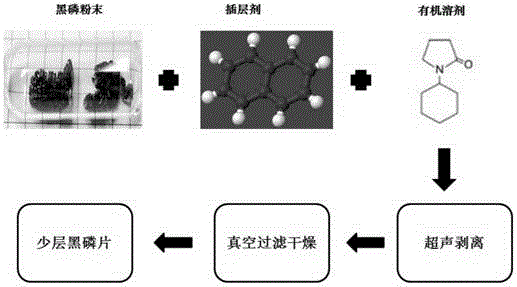

Method used

Image

Examples

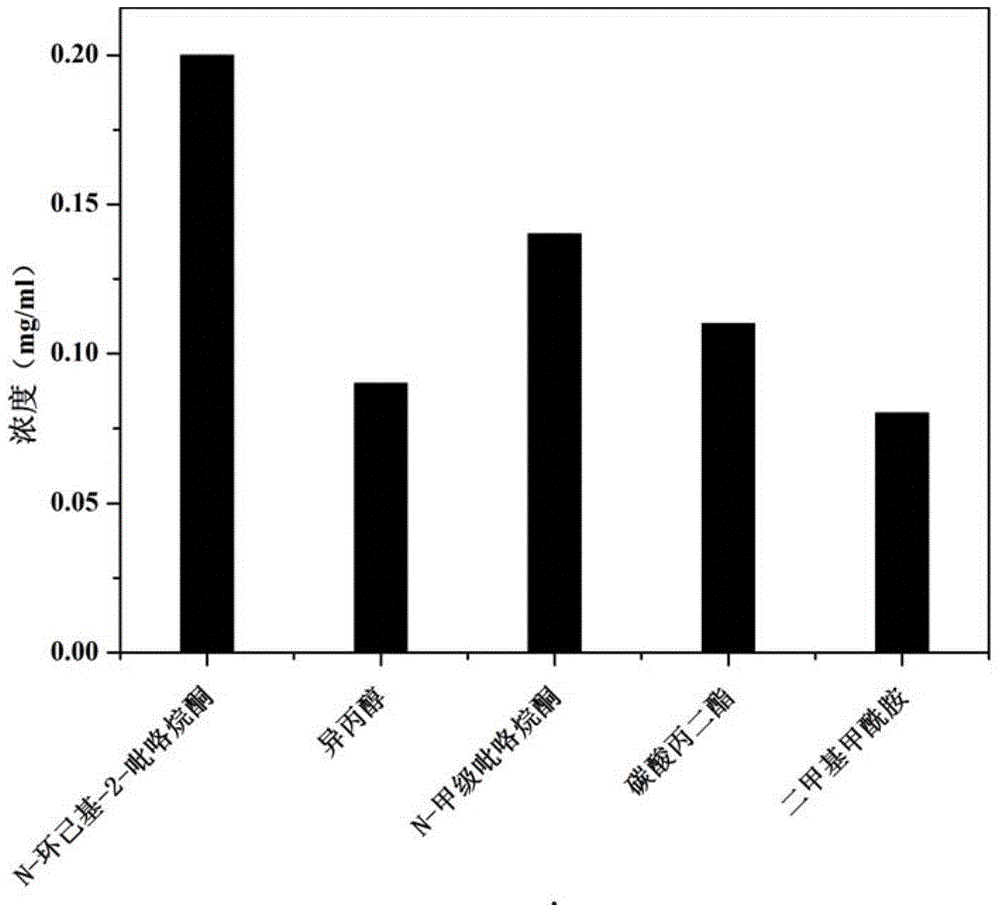

Embodiment 1

[0028] Put the black phosphorus powder and the intercalation agent into N-cyclohexyl-2-pyrrolidone (CHP) according to the mass ratio of 1:0.5, wherein the size of the black phosphorus powder is 50 μm, the intercalation agent is naphthalene, and the intercalation agent The concentration is controlled at 5mg / mL; the oxygen content and water content in the mixed solution are controlled to be lower than 20ppm, and the stripping reaction temperature is 40°C for 2 hours of ultrasonic reaction; the pore diameter of the vacuum filter membrane obtained by ultrasonic stripping is 0.1μm After vacuum filtration at 60°C, few-layer black phosphorus flakes can be obtained by vacuum drying.

Embodiment 2

[0030] Put the black phosphorus powder and the intercalation agent into N-cyclohexyl-2-pyrrolidone (CHP) according to the mass ratio of 1:1, wherein the size of the black phosphorus powder is 50 μm, the intercalation agent is naphthalene, and the intercalation agent The concentration is controlled at 10mg / mL; the oxygen content and water content in the mixed solution are controlled to be lower than 20ppm, and the stripping reaction temperature is 40°C for 1 hour of ultrasonic reaction; the pore diameter of the vacuum filter membrane obtained by ultrasonic stripping is 0.1μm After vacuum filtration at 60°C, few-layer black phosphorus flakes can be obtained by vacuum drying.

Embodiment 3

[0032] Put the black phosphorus powder and the intercalation agent into N-cyclohexyl-2-pyrrolidone (CHP) according to the mass ratio of 1:0.5, wherein the size of the black phosphorus powder is 50 μm, the intercalation agent is naphthalene, and the intercalation agent The concentration is controlled at 5 mg / mL; the oxygen content and water content in the mixed solution are controlled to be lower than 20 ppm, and the stripping reaction temperature is 60 ° C for 1 hour of ultrasonic reaction; the pore diameter of the vacuum filter membrane obtained by ultrasonic stripping is 0.1 μm After vacuum filtration at 60°C, few-layer black phosphorus flakes can be obtained by vacuum drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com