Method for preparing water-retaining biological organic fertilizer by using high-water-content poultry and livestock manure

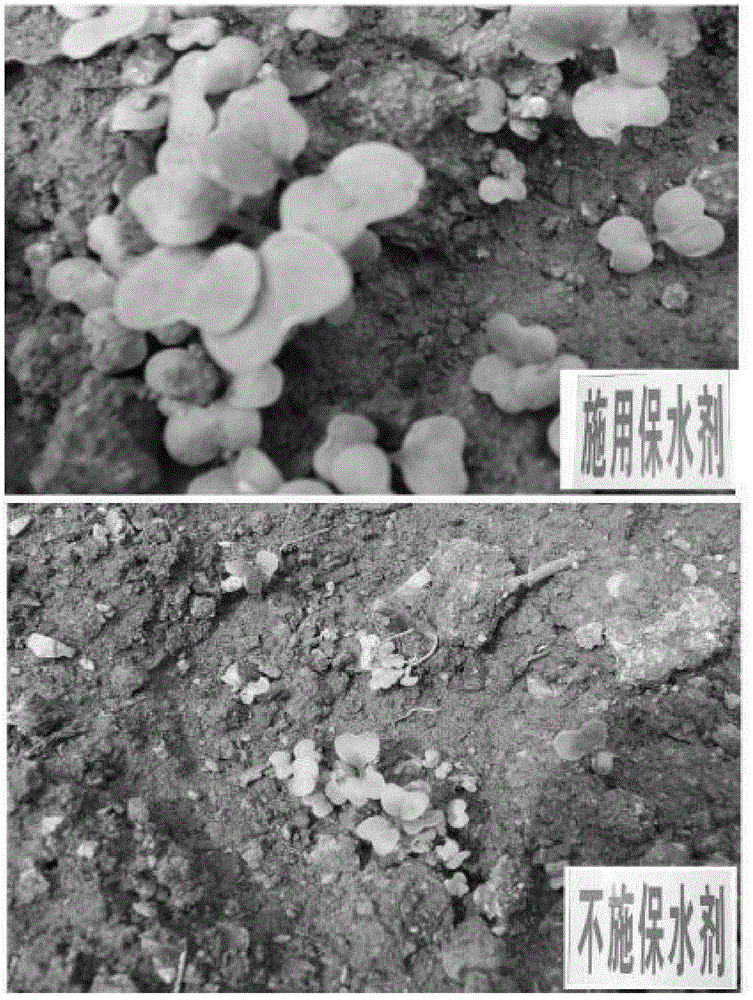

A technology of poultry manure and high water content, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problems of unreasonable use of chemical fertilizers, soil compaction, and lack of water resources, so as to promote sustainable development , improve the sanitation environment, and reduce the effect of mosquito breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Collect 10 tons of feces sewage with a water content ≥ 95% produced by the pig farm on the same day in a mixing tank, add 1500 kg of limestone powder, start the agitator to stir and mix evenly to form a feces slurry. From the quantitative discharge valve under the tank, the feces slurry is introduced into the screw conveyor reactor at a certain flow rate, and injected into the screw conveyor reactor with the corresponding sulfuric acid flow rate from the concentrated sulfuric acid storage tank (the total amount of sulfuric acid is 1050kg), and mixed with the feces slurry to react and solidify into solidified pig manure. Add 150kg of Zhuhai Nongshen brand soil bio-enzyme water-retaining agent, and ferment it into decomposed water-containing bio-organic fertilizer. Heating and dehydrating in a heating agitator until the water content is <12%, that is, about 3500kg of water-retaining bio-organic fertilizer is obtained.

Embodiment 2

[0028] Collect 10 tons of fecal sewage with a water content close to 100% produced by the pig farm on the same day in a mixing tank, add 2000 kg of wollastonite mineral powder, and start the agitator to stir and mix evenly to form a fecal slurry. From the quantitative discharge valve under the tank, the feces slurry is introduced into the screw conveyor reactor at a certain flow rate, and injected into the screw conveyor reactor with the corresponding sulfuric acid flow rate from the concentrated sulfuric acid storage tank (the total amount of sulfuric acid is 1300kg), and mixed with the feces slurry to react and solidify into solidified pig manure. Add 150kg of Zhuhai Nongshen brand soil bio-enzyme water-retaining agent, and mix and ferment to obtain water-containing and water-retaining bio-organic fertilizer. Heating and dehydrating in a heating agitator until the water content is <12%, that is, about 3900kg of stable water-retaining bio-organic fertilizer is obtained.

Embodiment 3

[0030] Collect 10 tons of feces sewage with a water content ≥ 90% produced by the pig farm on the same day in a mixing tank, add 1800 kg of lime powder, start the agitator to stir and mix evenly to form a feces slurry. From the quantitative discharge valve under the tank, the feces slurry is introduced into the screw conveyor reactor at a certain flow rate, and injected into the screw conveyor reactor with the corresponding sulfuric acid flow rate from the concentrated sulfuric acid storage tank (the total amount of sulfuric acid is 1710kg), and mixed with the feces slurry to react and solidify into solidified pig manure. Add 250kg of Zhuhai Nongshen brand soil bio-enzyme water-retaining agent to ferment into decomposed water-containing and water-retaining bio-organic fertilizer, heat and dehydrate in a heating mixer until the moisture content is <12%, and then obtain about 5300kg of stable water-retaining bio-organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com