Method for extracting paralytic shellfish toxins from shell raw materials

A shellfish toxin and shellfish technology, applied in the direction of organic chemistry, can solve the problems of geographical restrictions, low toxin content, and difficulty in extracting pure samples, etc., and achieve the effects of easy acquisition, improved extraction rate, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

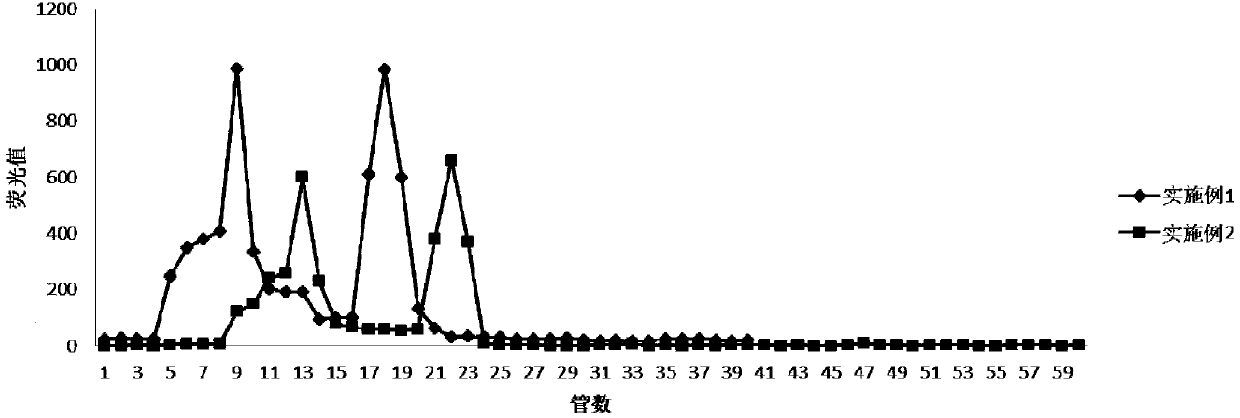

Embodiment 1

[0034] 1) Thaw the frozen Ezo scallop under running water, take the gonad and drain it, and weigh 1 kg. Homogenize with a homogenizer, put it into a beaker with a volume of 3 liters, add 1 liter of 0.1M acetic acid aqueous solution, stir well until the pH value of the mixture is 3, and use an ultrasonic breaker to crush for 10 minutes under the condition of 600W power , then heated in boiling water for 5 minutes, filtered with four layers of medical gauze after cooling, and collected the filtrate;

[0035] 2) Concentrate the filtrate obtained in step 1) under reduced pressure with a vacuum rotary evaporator until it reaches 0.3 liters, then refrigerate and centrifuge at 4°C for 10 minutes at 4000 rpm and a centrifugal radius of 5 cm, take the supernatant and put it in a separatory funnel. 150mLCHCl3 extracted twice to remove some fatty substances. Take the upper layer extract and mix it with 300mL ethanol, stir at room temperature for 24 hours, then perform a second centrifug...

Embodiment 2

[0041] 1) Remove the shell of the luxurious Chlamys farreri and take its gonads, drain and weigh 1 kg. Homogenize with a homogenizer, put it into a beaker with a volume of 3 liters, add 1 liter of 0.1M acetic acid aqueous solution, stir well until the pH value of the mixture is 2, and use an ultrasonic breaker to crush for 8 minutes under the condition of 600W power , then heated in boiling water for 10 minutes, filtered with four layers of medical gauze after cooling, and collected the filtrate;

[0042] 2) Concentrate the filtrate obtained in step 1) under reduced pressure with a vacuum rotary evaporator until it reaches 0.3 liters, then refrigerate and centrifuge at 4°C for 10 minutes at 5000 rpm and a centrifugal radius of 5 cm, take the supernatant and put it in a separatory funnel. Extract twice with 150mLCHCl3 to remove some fatty substances. Take the upper layer extract and mix it with 300mL ethanol and stir it at room temperature for 24 hours, then perform a second c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com