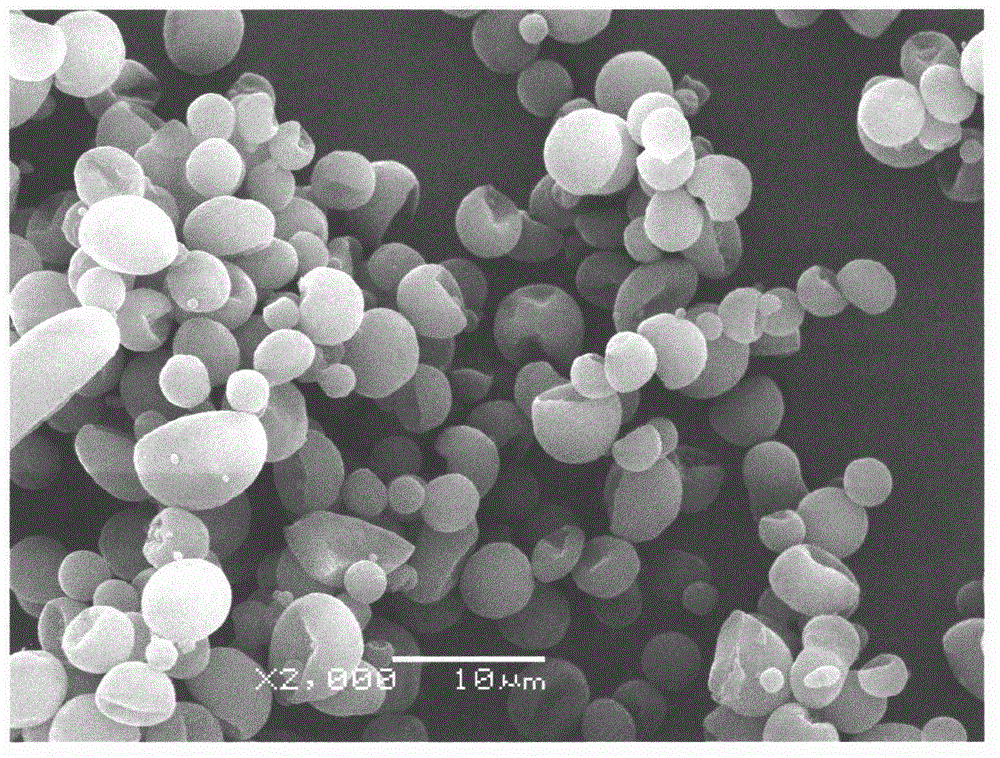

Preparation method of large-particle-size hollow polymer microspheres

A polymer, large particle size technology, applied in the field of hollow polymer microspheres, can solve problems such as viscosity increase, achieve the effects of less environmental pollution, easy to obtain, and avoid cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

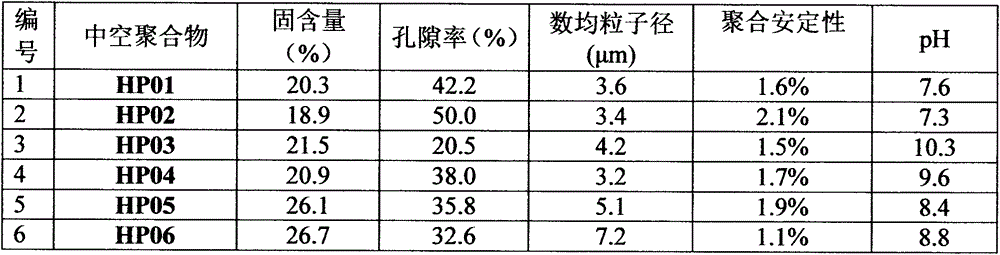

Examples

Embodiment 1

[0048] (1) Weigh 75g MgCl2 6H2O and dissolve it in 1000g deionized water to obtain MgCl2 solution, and then weigh 42g NaOH solid and dissolve it in 450g deionized water to obtain NaOH solution. Slowly add NaOH solution to MgCl2 under mechanical stirring at a speed of 650rpm In the solution, stir for 50min to obtain Mg(OH)2 colloid, which is used as a dispersant for subsequent use.

[0049] (2) Weigh 0.8g DAP (p-phenylenediamine) and dissolve it in 100g deionized water to form a water phase; successively weigh 32g of BPO (benzoyl peroxide), 250g of St (styrene), and MA (methyl acrylate) 150g, TDM (dodecyl mercaptan) 4.00g, stirring and dissolving to form a dispersed phase; under mechanical stirring at a speed of 650rpm, add the water phase and the dispersed phase to the Mg(OH)2 dispersant in turn, and maintain the pre-emulsification for 30min Add the obtained pre-emulsion into a high-speed shear disperser, emulsify and disperse for 30 min at a shear speed of 12000 rpm, rinse wi...

Embodiment 2

[0051] (1) Weigh 75g MgCl2 6H2O and dissolve it in 1000g deionized water to obtain MgCl2 solution, and then weigh 42g NaOH solid and dissolve it in 450g deionized water to obtain NaOH solution. Slowly add NaOH solution to MgCl2 under mechanical stirring at a speed of 650rpm In the solution, Mg(OH)2colloid is prepared, which is used as a dispersant for subsequent use.

[0052] (2) Weigh 1.2g of DAP (p-phenylenediamine) and dissolve it in 100g of deionized water to prepare the water phase; successively weigh 32g of BPO (benzoyl peroxide), 220g of St (styrene), and 220g of MA (methyl acrylate). ) 180g, TDM (dodecyl mercaptan) 8.00g, stirring and dissolving to form a dispersed phase; under mechanical stirring at a speed of 650rpm, add the water phase and the oil phase to the Mg(OH)2 dispersant in turn to maintain pre-emulsification 30min; the obtained pre-emulsion was added to a high-speed shear disperser, and at a shear speed of 12000rpm, emulsified and dispersed for 25min, after...

Embodiment 3

[0054] (1) Weigh 97.60g MgCl2 6H2O and dissolve it in 1000g deionized water to obtain MgCl2 solution, and then weigh 67.21g NaOH solid and dissolve it in 450g deionized water to obtain NaOH solution. Add MgCl2 solution to prepare Mg(OH)2 colloid, which is used as a dispersant for later use.

[0055] (2) Weigh 0.04g DAP (p-phenylenediamine) and dissolve it in 100g deionized water to form an aqueous phase; successively weigh 32g of BPO (benzoyl peroxide), 392g of St (styrene), and MA (methyl acrylate) 8g, TDM (dodecyl mercaptan) 2.00g, stirring and dissolving to form a dispersed phase; under mechanical stirring at a speed of 650rpm, add the water phase and the dispersed phase to the Mg(OH)2 dispersant in turn, and maintain the pre-emulsification for 30min The obtained pre-emulsion is joined in the high-speed shear disperser, and under the shear speed of 10000rpm, the emulsification is dispersed for 30min, and after the emulsification finishes, the emulsifier is rinsed with 100g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com