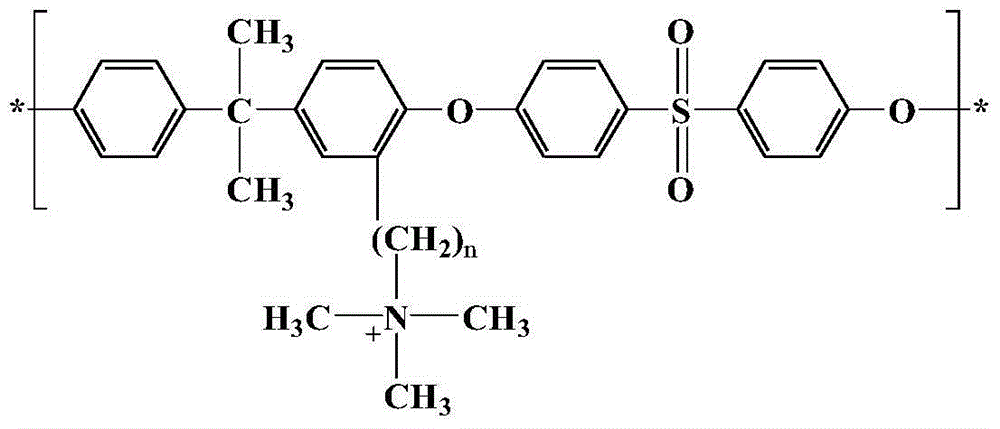

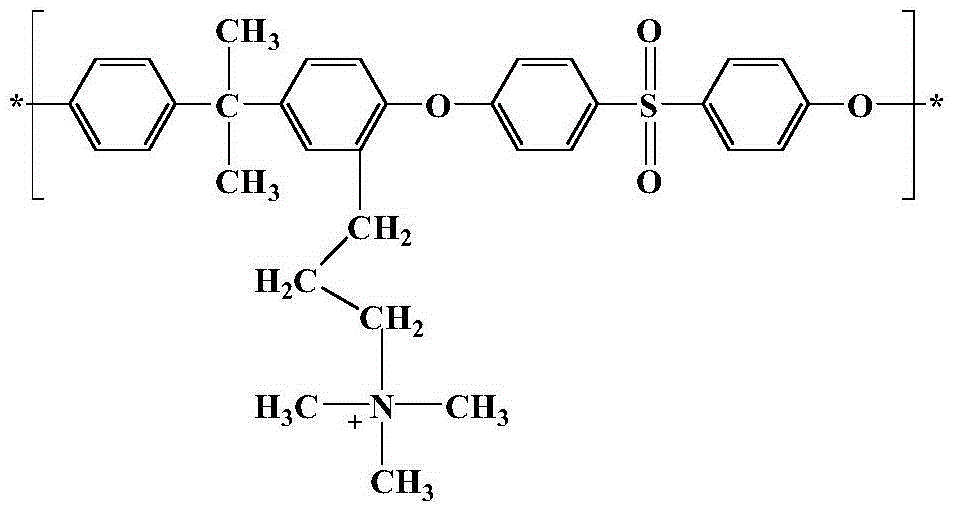

Long-branched-chain polysulfone anionic membrane and preparation method thereof

An anion exchange membrane and long-chain branched technology, which is applied in the field of long-chain branched polysulfone anion membrane and its preparation, can solve the problems of reduced mechanical properties of the membrane and increased water absorption, so as to reduce swelling, improve connectivity, and enhance phase The effect of separation drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

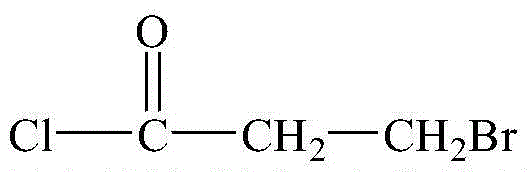

Embodiment 1

[0021] Because the acylation reaction requires anhydrous reaction, various flasks and other instruments need to be vacuumed under double-row tubes before the experiment. When vacuuming, the flask should be burned with an alcohol lamp. After the burning is stopped, vacuum should be drawn until the flask is cooled. Pour in inert gas such as nitrogen, and then vacuum, repeat 2-3 times in this way, and then add 1g PSF solid and 40ml dichloromethane (put into active molecular sieve one week in advance) to dissolve at room temperature under nitrogen protection. After dissolving, add 2ml of anhydrous tin tetrachloride, then place the reaction in an ice-water bath, 15 minutes later when the temperature drops to 3℃, mix 1ml of acylating reagent 3-bromopropionyl chloride with 10ml of dichloromethane In the normal pressure dropping funnel, under the protection of nitrogen, slowly drip the reaction liquid. Because the acylation reaction will emit hydrogen chloride gas, a bubbler is connect...

Embodiment 2

[0030] The flask was evacuated under a double-row tube, and then under the protection of nitrogen, 1g PSF solid and 40ml dichloromethane (put into the active molecular sieve one week in advance) were added to dissolve at room temperature. After dissolving, add 2ml of anhydrous tin tetrachloride, and then place the reaction in an ice-water bath. After 15 minutes, when the temperature drops to 3℃, mix 1ml of acylation reagent 6-bromohexanoyl chloride with 10ml of dichloromethane. In the normal pressure dropping funnel, under the protection of nitrogen, slowly drip the reaction liquid. Because the acylation reaction will emit hydrogen chloride gas, a bubbler is connected to the other outlet of the flask while dripping, and then a rubber tube is connected to the water to absorb the gas generated by the reaction and ensure that the pressure in the flask is moderate. The dripping is completed for 20 minutes. Then the ice water bath was removed, and the reaction was allowed to react ...

Embodiment 3

[0038] The flask was evacuated under a double-row tube, and then under nitrogen protection, 0.5 g of PSF solid and 15 ml of dichloromethane (put into the active molecular sieve one week in advance) were added to dissolve at room temperature. After dissolving, add 2ml of anhydrous tin tetrachloride, and then place the reaction in an ice water bath. After 15 minutes, when the temperature drops to 3℃, mix 2ml of acylating reagent 6-bromohexanoyl chloride with 10ml of dichloromethane. In the normal pressure dropping funnel, under the protection of nitrogen, slowly drip the reaction liquid. Because the acylation reaction will emit hydrogen chloride gas, a bubbler is connected to the other outlet of the flask while dripping, and then a rubber tube is connected to the water to absorb the gas generated by the reaction and ensure that the pressure in the flask is moderate. The dripping is completed for 20 minutes. Then the ice water bath was removed, and the reaction was allowed to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com