Aerobiotic and anaerobic coupled two-phase fermentation marsh gas generation process method

A process method and biogas production technology, applied in the direction of fermentation, biosynthesis, waste fuel, etc., can solve the problems of slow degradation of crude fiber, difficulty in heat and mass transfer of fermentation, difficulty in continuous operation, etc., to solve the problem of resource utilization, Effects of improving environmental pollution and increasing gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

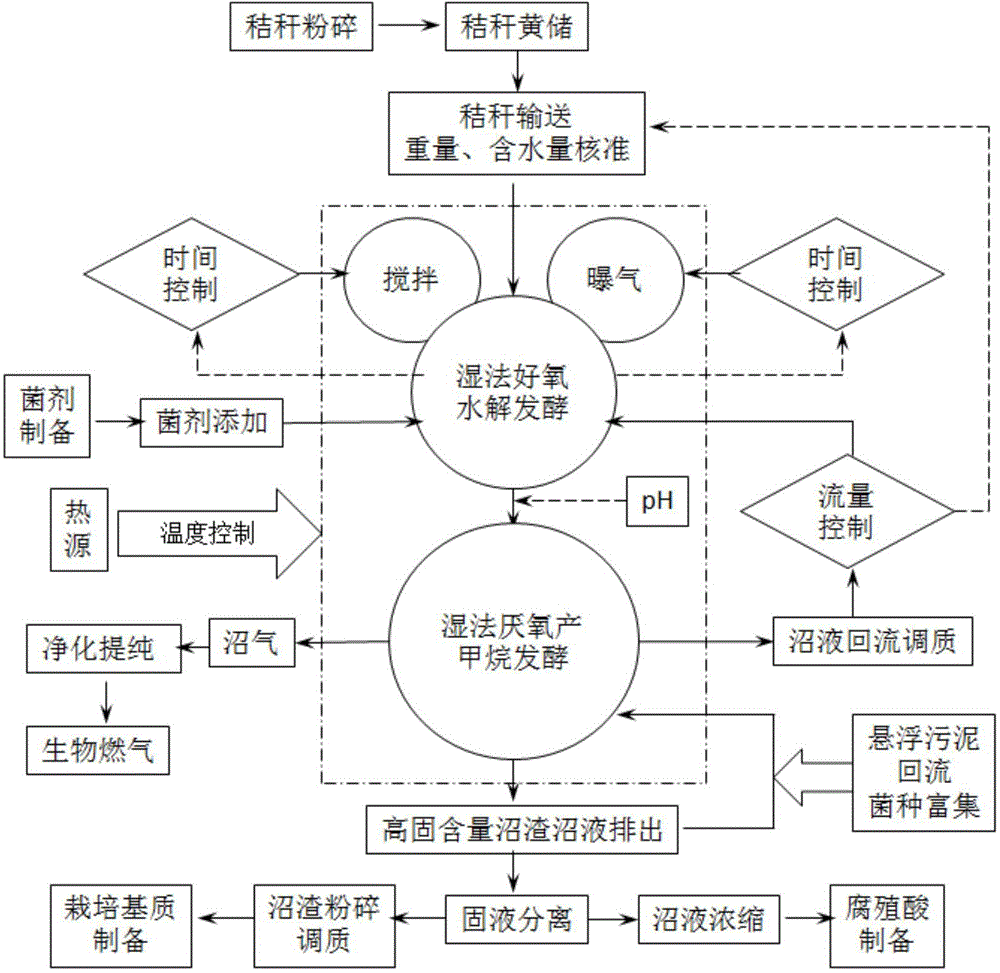

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] A process method for producing biogas by coupling aerobic and anaerobic two-phase fermentation, the steps of the method are as follows:

[0016] ①Batching and mixing: Crush the crop straw into straw raw materials with a particle size of 10-30mm. After yellow storage, mix it with the methane-producing fermentation phase backflow biogas slurry. The total solid concentration of the mixed slurry is 6-10%. Materials are evenly mixed;

[0017] ② Wet aerobic hydrolysis fermentation: send the mixed homogeneous material obtained above into the wet aerobic hydrolysis fermentation reactor for aerobic hydrolysis acidification, heating, and control the temperature of the aerobic acid production fermentation phase to 30-42 ℃ for medium temperature fermentation, Control the period and frequency of aeration and agitation according to the dissolved oxygen and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com