Macromolecule solid micro needle and batched preparing method thereof

A polymer and polymer material technology, applied in the field of polymer solid microneedles and their batch preparation, can solve the problems of human body damage, broken skin, and increased risk of microneedle use, and achieve good durability, low price, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

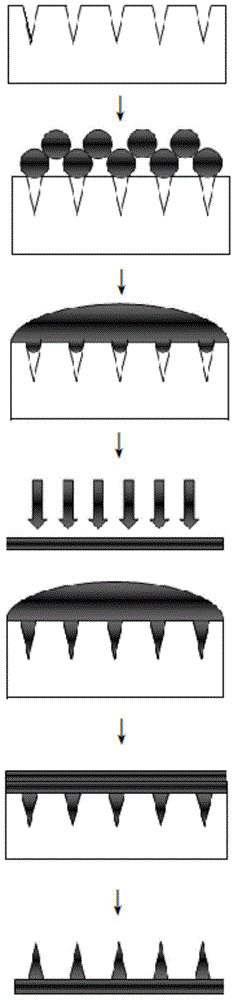

[0034] 1) Mix polydimethylsiloxane and aminoethylpiperazine curing agent at a mass ratio of 10:1, stir well and vacuumize to remove air bubbles, then place them in a horizontal container and place them in an oven at 60°C Heating in a medium temperature for 8 hours to obtain solid polydimethylsiloxane, then take it out from the container, and use laser cutting and micro-nano processing technology to prepare micro-needle molds;

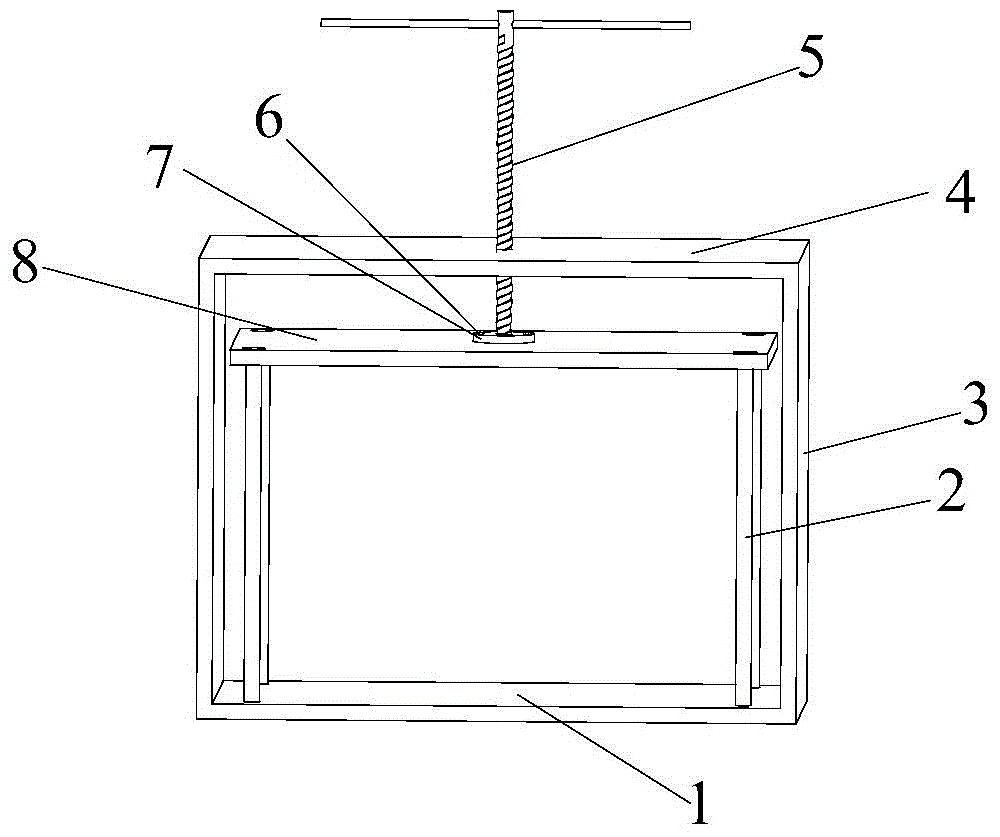

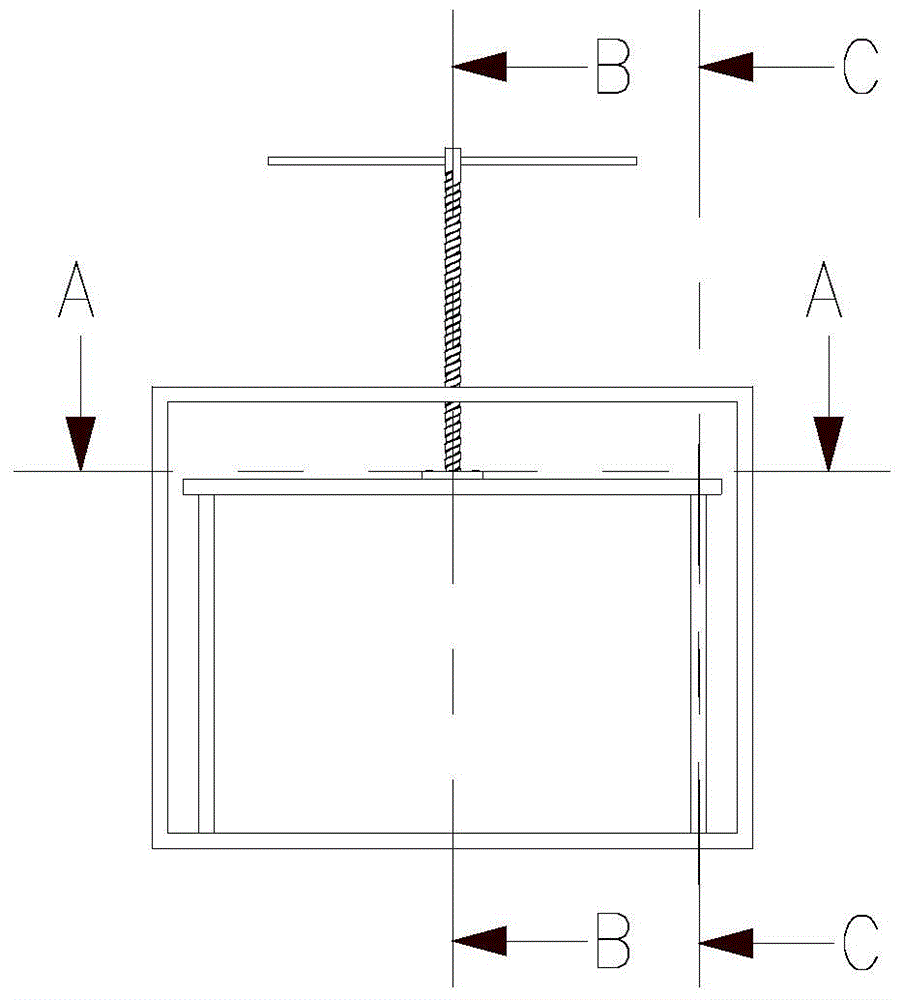

[0035] 2) Fix the microneedle mold on the bottom plate of the preparation device, then place polylactic acid particles on the microneedle mold, and then place the entire preparation device in a closed heating device to heat until the particles melt, and the heating temperature is 180°C;

[0036] 3) The preparation device is taken out from the closed heating device, and the melt of polylactic acid is molded while hot through the preparation device;

[0037] 4) cooling the preparation device to room temperature, and then demoulding through the preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com