Tanning wastewater gas deodorization system and method

A technology for tanning wastewater and gas, applied in separation methods, chemical instruments and methods, air quality improvement and other directions, can solve the problems of unfavorable popularization and application, secondary pollution, high cost, and achieve easy removal, easy replacement, and increased contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

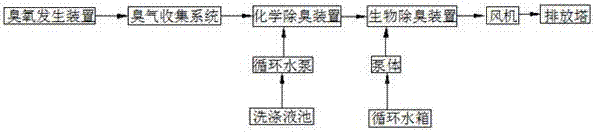

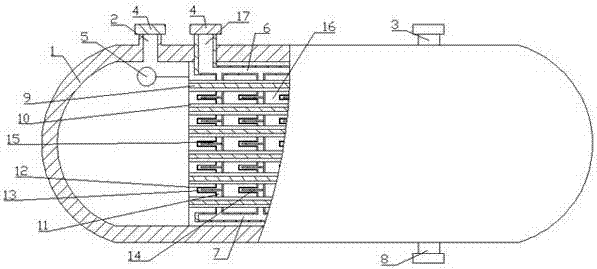

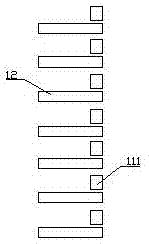

[0013] Example 1, such as figure 1 The gas deodorization system for tannery wastewater shown includes an ozone generator, an odor collection device, a chemical deodorizer, a biological deodorizer, a washing liquid tank, a circulating water tank, a supplementary tank and a discharge tower. The ozone outlet of the ozone generator is The gas port is connected to the odor collection device through a pipeline, so that the prepared ozone is passed into the odor collection device for preliminary purification through the strong oxidizing property of ozone. The gas outlet of the odor collection device is sequentially connected with a chemical deodorization device, a biological deodorization device, and a discharge tower, so that the odor is purified by chemical methods and biological methods in sequence, and finally the odor is discharged through the discharge tower. A fan is connected between the biological deodorization device and the discharge tower, and the gas is sucked into the d...

Embodiment 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the washing liquid used is a mixture of liquid alkali and water, and the formula of liquid alkali and water is determined according to the pH value of the final discharged treatment liquid. By adjusting the liquid The ratio of alkali and water keeps the pH value of the treatment liquid at 7.

Embodiment 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the washing liquid used is a mixture of liquid alkali and water, and the formula of liquid alkali and water is determined according to the pH value of the final discharged treatment liquid. By adjusting the liquid The ratio of alkali and water keeps the pH value of the treatment liquid at 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com