Smelting method for industrial silicon

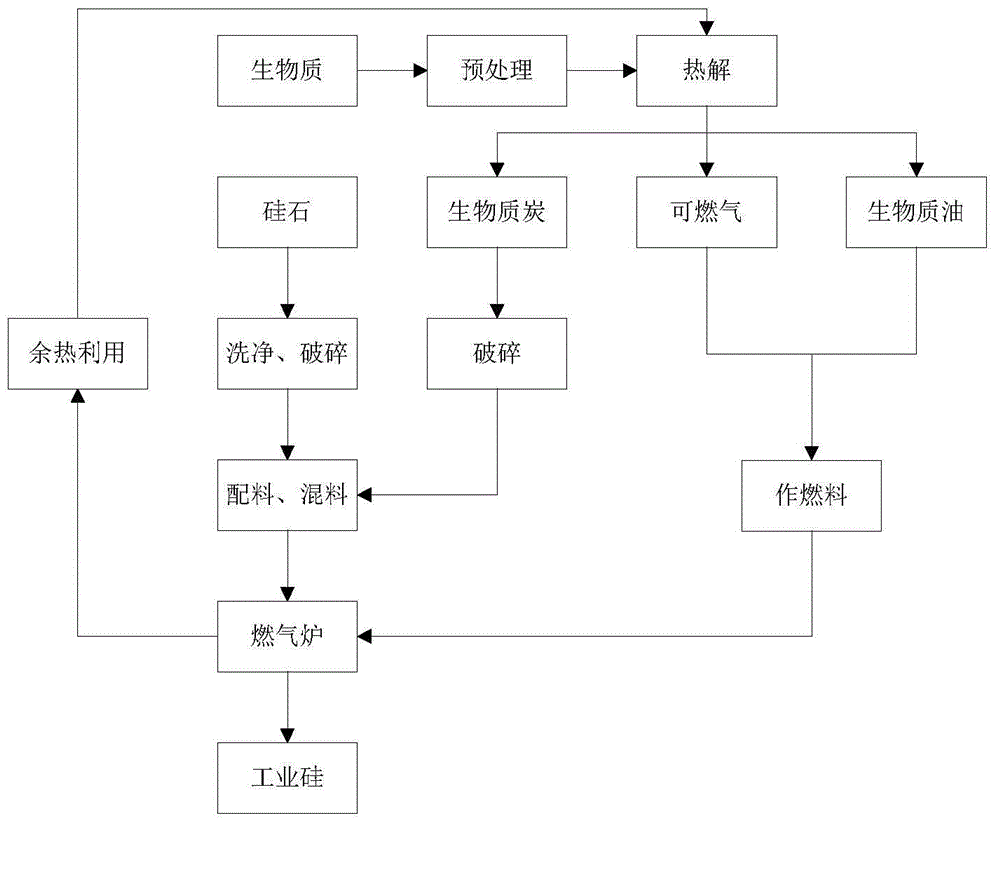

A smelting method, a technology for industrial silicon, applied in the petroleum industry, chemical instruments and methods, coke ovens, etc., can solve the problem of not mentioning the source of reducing agents and fuel sources, not mentioning the comprehensive utilization of biomass, and not mentioning how to produce Industrial silicon and other problems, to achieve the effect of improving process thermal efficiency and production efficiency, high comprehensive utilization value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] Example 1. After pretreatment, the biomass was put into a pyrolysis furnace for pyrolysis. The pyrolysis temperature was 450° C., and the pyrolysis time was 60 minutes. The fixed carbon content of the obtained biochar was 77.33%. Select the SiO2 content of silica ≥ 99.4%, Fe2O3 content ≤ 0.15%, Al2O3 content ≤ 0.2%, CaO content ≤ 0.1%, crush and sieve the silica to a particle size of 60-80mm as the silicon source, and use the pyrolyzed biomass charcoal Broken to less than 10mm as a reducing agent. Then mix the silica and the reducing agent in a mass ratio of 100:41, mix them evenly, and place them in a gas-fired heating furnace for reduction. The reduction temperature is 1950°C and the reduction time is 3.5 hours. The Si grade of the obtained industrial silicon is ≥99%, and other indicators of the industrial silicon meet the national standard GB / T2881-2008.

example 2

[0051] Example 2. After pretreatment, the biomass was put into a pyrolysis furnace for pyrolysis. The pyrolysis temperature was 600° C. and the pyrolysis time was 45 minutes. The fixed carbon content of the obtained biochar was 83.21%. Select the SiO2 content of silica ≥ 99%, Fe2O3 content ≤ 0.3%, Al2O3 content ≤ 0.3%, CaO content ≤ 0.1%, crush and sieve the silica to a particle size of 50-100 mm as the silicon source, and pyrolyze the biochar Broken to less than 10mm as a reducing agent. Then mix the silica and the reducing agent in a mass ratio of 100:32, mix them evenly, and place them in a gas-fired heating furnace for reduction. The reduction temperature is 2350°C and the reduction time is 2.5 hours. The Si grade of the obtained industrial silicon is ≥99%, and other indicators of the industrial silicon meet the national standard GB / T2881-2008.

example 3

[0052] Example 3. After pretreatment, the biomass was put into a pyrolysis furnace for pyrolysis. The pyrolysis temperature was 700° C. and the pyrolysis time was 30 minutes. The fixed carbon content of the obtained biochar was 85.19%. Select the SiO2 content of silica ≥ 99.2%, Fe2O3 content ≤ 0.2%, Al2O3 content ≤ 0.2%, CaO content ≤ 0.1%, crush and sieve the silica to a particle size of 50-90mm as the silicon source, and use the pyrolyzed biomass charcoal Broken to less than 10mm as a reducing agent. Then mix the silica and the reducing agent in a mass ratio of 100:47, mix them evenly and place them in a gas heating furnace for reduction. The reduction temperature is 2100°C and the reduction time is 3 hours. The Si grade of the obtained industrial silicon is ≥99%, and other indicators of the industrial silicon meet the national standard GB / T2881-2008.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com