A kind of gypsum-based wave-absorbing composite material and its preparation method

A composite wave absorbing material and gypsum-based technology, which is applied in the field of building materials to achieve the effect of simple and feasible production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the present embodiment, the mass percent that each raw material occupies is as follows:

[0025] Gypsum powder accounts for 75%; wave absorbing agent accounts for 15%, including carbon black 2%, manganese zinc ferrite 13%; expanded perlite accounts for 10%; The ratio is 0.5:100; the weight ratio of dry material to water is 0.6:1.

[0026] Prepared as follows:

[0027] 1) Mix dry materials and dry mix evenly;

[0028] 2) Add water to the dry material and mix well;

[0029] 3) Pour the mixture in step 2) into a mould, vibrate and mold, remove the mold after 24 hours of molding, and maintain for 28 days under standard conditions.

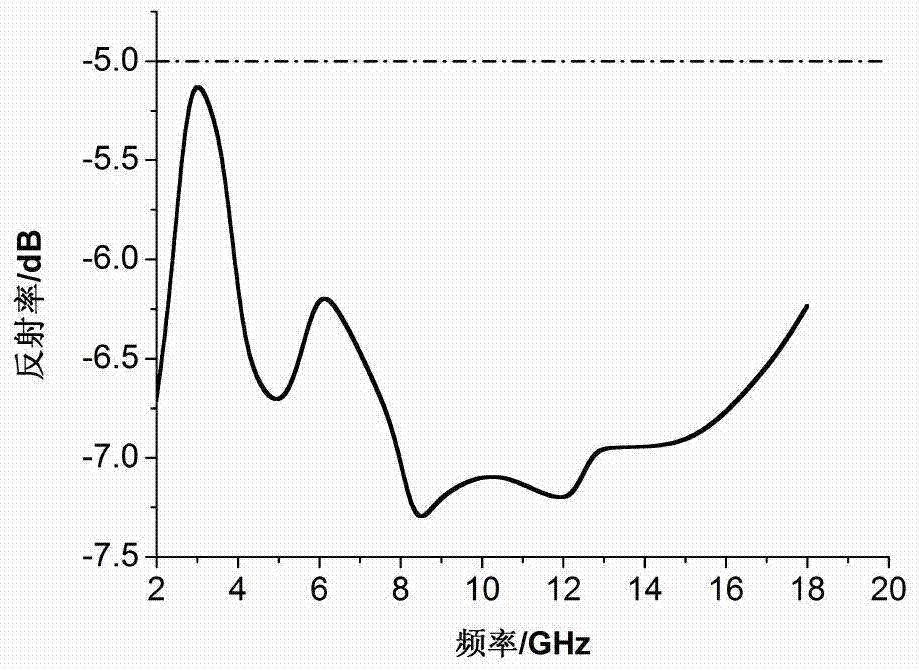

[0030] The sample prepared in this embodiment is tested for absorbing performance, and the reflectivity curve is shown in figure 1 shown.

Embodiment 2

[0032] In the present embodiment, the mass percent that each raw material occupies is as follows:

[0033] Gypsum powder accounts for 75%; wave absorbing agent manganese zinc ferrite powder accounts for 20%; expanded vitrified microspheres account for 5%; the ratio of polycarboxylate high-performance water reducer to the total weight of dry materials is 0.5:100; The weight ratio of material to water is 0.65:1.

[0034] Prepared as follows:

[0035] 1) Mix and dry mix the dry materials evenly;

[0036] 2) Add water to the dry material and mix well;

[0037] 3) Pour the mixture in step 2) into a mould, vibrate and mold, remove the mold after 24 hours of molding, and maintain for 28 days under standard conditions.

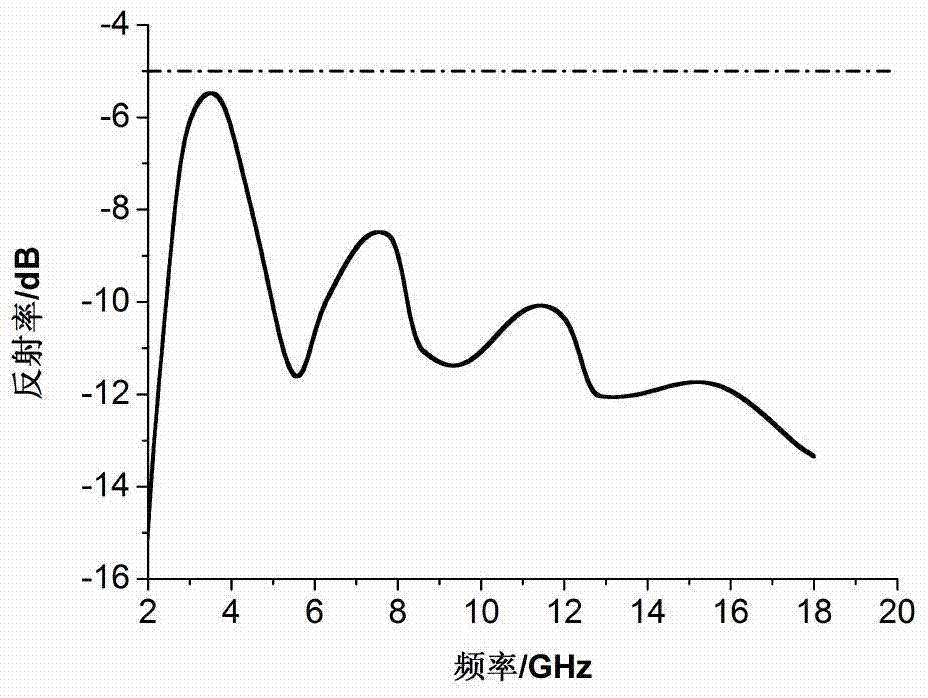

[0038] The sample prepared in this embodiment is tested for absorbing performance, and the reflectivity curve is shown in figure 2 shown.

Embodiment 3

[0040] In the present embodiment, the mass percent that each raw material occupies is as follows:

[0041] Gypsum powder accounts for 75%; wave absorbing agent accounts for 15%, including expanded graphite 5%, carbonyl iron powder 10%; expanded perlite accounts for 10%; the ratio of polycarboxylate high-performance water reducer to the total weight of dry materials is 0.8:100; the weight ratio of dry material to water is 0.55:1.

[0042] Prepared as follows:

[0043] 1) Mix dry materials and dry mix evenly;

[0044] 2) Add water to the dry material and mix well;

[0045] 3) Pour the mixture in step 2) into a mould, vibrate and mold, remove the mold after 24 hours of molding, and maintain for 28 days under standard conditions.

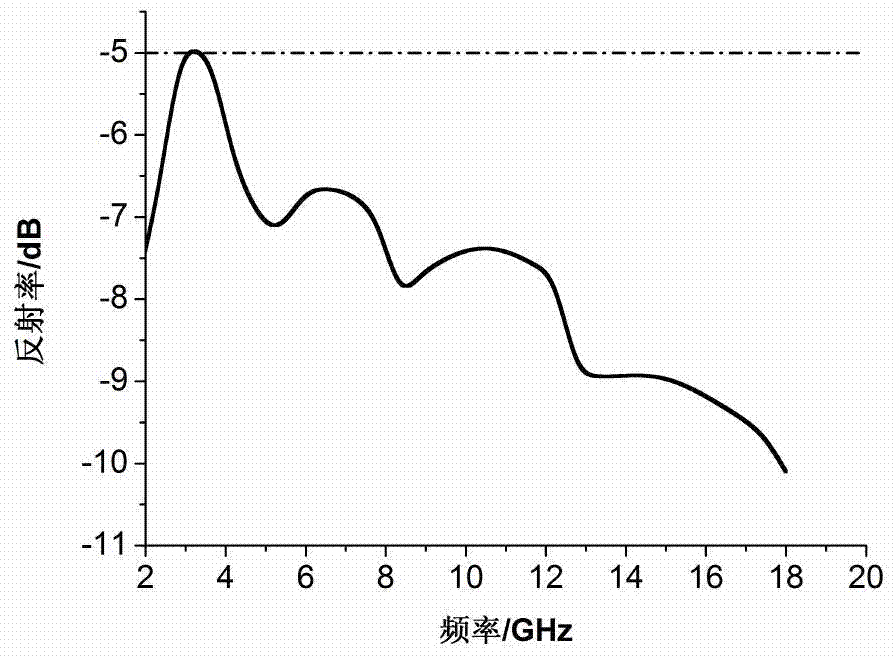

[0046] The sample prepared in this embodiment is tested for absorbing performance, and the reflectivity curve is shown in image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com